Dyna-Purge, Div. of Shuman Plastics, Inc.

35 Neoga St.

Depew (Buffalo), NY 14043 US

866-607-8743 | 716-685-2121

dynapurge.com

About Dyna-Purge, Div. of Shuman Plastics, Inc.

Buy your surplus obsolete and scrap plastic materials.

Produce and supply consistent quality plastic compounds.

Supply quality plastic material in various forms, including: regrind, off-grade and virgin.

Provide dependable plastic recycling and toll processing services.

IS THIS YOUR COMPANY?

Video Gallery

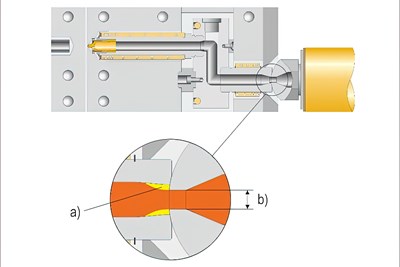

Extrusion Blow Molding

Thank you for taking time to learn more about how Dyna-Purge can help you! For additional information or assistance please visit ...

Extrusion Shut Down and Start Up

Thank you for taking time to learn more about how Dyna-Purge can help you! For additional information or assistance, please visit ...

Blown Film Extrusion – While Maintaining Bubble

Thank you for taking time to learn more about how Dyna-Purge can help you! For additional information or assistance, please visit ...

Injection Start Up & Shut Down

Thank you for taking time to learn more about how Dyna-Purge can help you! For additional information or assistance, please visit ...

As Seen On Plastics Technology

Dyna-Purge, Div. of Shuman Plastics, Inc. Supplies the Following Products

Trade Names Offered by Dyna-Purge, Div. of Shuman Plastics, Inc.

- Dyna-Purge