Injection Molding Solutions Scientific Molding

1019 Balfour St.

Midland, MI 48640 US

989-832-2424

scientificmolding.com

IS THIS YOUR COMPANY?

As Seen On Plastics Technology

Injection Molding Solutions Scientific Molding Supplies the Following Products

- Consultants - Design, Manufacturing, Purchasing

- R&D, Training Institutes

- Training Programs in Plastics

- Troubleshooting, Problem Solving Systems

Editorial, News, and Products

-

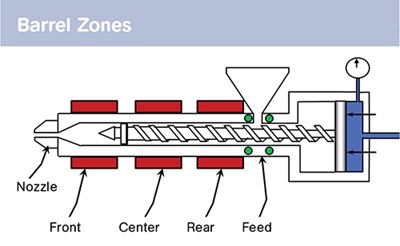

How to Set Barrel Zone Temps in Injection Molding

Start by picking a target melt temperature, and double-check data sheets for the resin supplier’s recommendations. Now for the rest...

-

What to Do About Weak Weld Lines

Weld or knit lines are perhaps the most common and difficult injection molding defect to eliminate.

-

Are Your Sprue or Parts Sticking? Here Are Some Solutions

When a sprue or part sticks, the result of trying to unstick it is often more scratches or undercuts, making the problem worse and the fix more costly. Here’s how to set up a proper procedure for this sticky wicket.

-

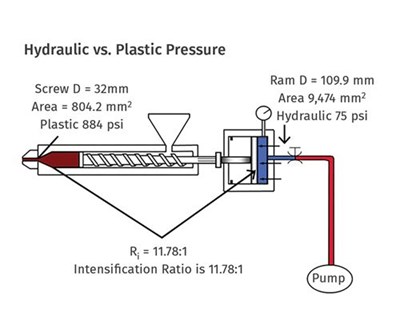

Understanding Intensification Ratio

A first step in taking the “art” out of molding.

-

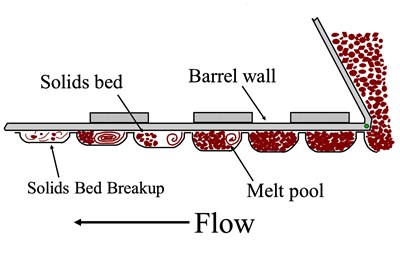

Improve Quality & Productivity With Advanced Screw Design

Most molders are still running with screw designs that haven’t changed much in 30 years. But they don’t need to.

-

How to Stop Flash

Flashing of a part can occur for several reasons—from variations in the process or material to tooling trouble.

-

A Simpler Way to Calculate Shot Size vs. Barrel Capacity

Let’s take another look at this seemingly dull but oh-so-crucial topic.

-

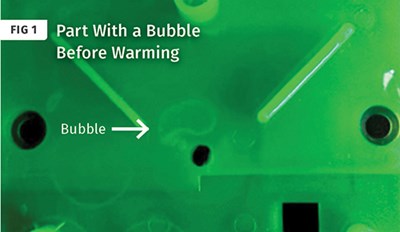

How to Get Rid of Bubbles in Injection Molding

First find out if they are the result of trapped gas or a vacuum void. Then follow these steps to get rid of them.

-

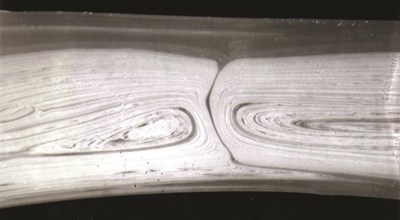

The Awful Truth About Weld Lines

As everyone knows, weld lines are weak points. What’s less well known is just what’s going on inside that weld line on a microstructural level. Here’s a close-up look at some nasty little secrets.

-

What’s Controlling Your Cycle Time? Part 1

Follow these guidelines to maximize your profits.

-

How Does Your Molding Machine Control Pack Pressure?

It seems some new machines have pack velocity issues, as machine builders are confusing processors with controllers that are more complicated than they need to be and less user-friendly.

-

Injection Molding: Understand the Link Between Feed Throat Temperature & Bridging

Save time and money by properly controlling the feed-throat temperature. In some cases—but not all—it can help you solve a bridging problem.

-

How to Know When Your Process is Ready to Make Acceptable Parts

Focus on six key metrics to help you determine when a process is lined out and stable enough to start production.

-

Fast, Simple, Low-Cost Method Unveils ‘True’ Melt Temperature

Long a mystery to injection molders, actual temperature of melt entering the mold is said to be revealed by an easy procedure that is repeatable and takes less than a minute.

-

Need Help with a Molding Project to Counter the Coronavirus?

Expert help at a steep discount, and the fee goes to a COVID-19 related charity.

-

Follow These Tips to Sanitize Machine Controller Screens & Buttons

Keeping your workers safe from the coronavirus makes it extremely important to institute a sanitizing procedure on all touch surfaces of the controller, screen and operating panel. I did some research and here’s what I found.

-

In Search of a Universal Setup Sheet

Duplicating a process from one injection machine to another is frustrating and time-consuming. Develop a mold-specific setup sheet that works in all kinds of presses by differentiating plastic parameters from machine parameters and duplicating those plastic conditions from machine to machine, electric or hydraulic.

-

Revisiting Shot Size vs. Barrel Capacity

We’ve covered this topic before, but it’s important enough to warrant another look..

-

Tension-Indicating ‘Smart’ Bolts Make Mold Mounting Safer, More Efficient

No more guessing about whether mold-mounting bolts are tightened properly, with an alternative to unreliable torque measurements.

-

Prices for Nearly All Volume Resins Down

Flat pricing projected in fourth quarter for volume resins.

-

Graphing Injection Pressure: What Should Pack & Hold Curves Show?

Are you sure your press is doing what you want? Visit your controller often to ensure your machines plot the pressure vs. time graph for all your processes. Here let’s focus on pack and hold.

-

To Succeed in Manufacturing, Focus on Your People First

It’s not easy being a custom injection molder in the NYC metro area. For Natech Plastics, the key is developing employees’ skills and commitment.

-

How to Deal With Residual Stress in Molded Parts

Here are design, molding, and fixturing considerations to help you handle this unavoidable issue.

-

How to Quickly Verify Your Machine & Process Setpoints

For a quick check of your process setup, the injection-pressure-vs.-time graph is your best tool.

-

PART 2: The Importance of Consistent Fill Time

To make identical parts, you need to keep fill time constant. In part one we covered the why. Here’s the how.

-

Part 1: The Importance of Consistent Fill Time

To make identical parts, you need to keep fill time constant. Here’s why.

-

Injection Molding: How Backpressure Adjustments Influence Shot Size

Raising backpressure results in increasing shot size, which can cause a host of other problems.

-

B&B Molders Sticks to Its Core— Core Values & Core Competencies

To compete in today’s market, you need good technology, but you also need to know what you stand for and what you’re good at.

-

INJECTION MOLDING: Setting Mold Protection Takes Time But Saves More

Mold protection is often neglected, but it more than pays for the time and attention required.

-

MRPC Takes ‘Holistic’ Approach To Scientific Molding

Last year this family-owned molder made a major commitment to Scientific Molding by starting a training process involving all employees.

-

A New Look at Evaluating Fill Times For Injection Molding

One of the important process parameters to establish and record for any injection molded part is its injection or fill time. Research research reveals the limitations of popularly taught methods of establishing this critical parameter.

-

Understanding Polymer Flow: Interpreting the Viscosity Curve

Take the time to do the viscosity curve on new molds. You will learn more in that hour than many learn in years about the process for this tool.

-

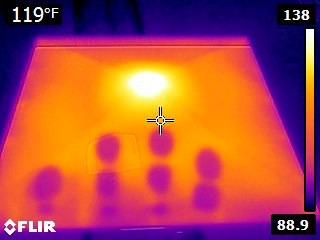

Taking the Temperature of Mold Productivity

Increasing traffic in transfer tooling from molders that have shuttered operations or are unable to successfully produce parts is driving interest in a long-established but under-utilized diagnostic technique for injection molding.

-

Injection Molding: How to Set Second-Stage (Pack & Hold) Pressure

Most molders work with two parameters for establishing second-stage pressure. But within Scientific Molding there are actually four.

-

Injection Molding: Understanding Pressure Loss In Injection Molding

One of the more prominent trends in processing is the need for higher plastic pressures to mold parts.

-

Injection Molding: Processors: Teach Part Designers The Golden Rule

Make sure the designers you work with understand that there are limits to what processing can do.

-

Injection Molding: Why & How to Do Gate-Seal Experiments

Part of optimizing any molding process is determining the second-stage injection, or pack and hold, parameters.

-

On-Site: An ‘Empire’ Built on Scientific Molding

A U.S. custom injection molder that’s hiring?

-

Injection Molding: The Basics of Machine Evaluation, Part III

In the last two issues, we started defining some basic tests to ensure your injection molding machine is working properly.

-

How to Make the Transition to Electric Presses

Electric injection machines are becoming more and more prevalent, and as they hit the shop floor, you are responsible for making them produce parts with dimensions, appearance, and performance to client specifications.

-

Balanced Filling Is Critical for Holding Molding Tolerances

Processors face a multitude of challenges whenever they approach an injection molding machine.

-

Injection Molding Know-How: The ABCs of Delta P: Setting the First-Stage Pressure Limit

Here’s another trick of the trade that will make your life easier.

-

How to Solve Uneven Clamping

Of the hundreds of variables involved in injection molding, clamping mechanisms and platens often get less attention than they deserve.

-

Find the Source of Visual Defects

The appearance of visual defects on parts such as cracking, crazing, grooves, ripples, wave marks, and flaky brittleness often indicates more than an aesthetic problem.

-

Sticking Sprues or Parts? Lots of Possible Causes and Solutions

Material sticking in the mold can be a production killer, whether it is the sprue or the formed part in the cavity.

-

Eliminate Blemishes on Cosmetic Parts

Black specks, streaks, or poor color mixing are the most common problems that mar the appearance of cosmetic injection molded parts.