Momentive Performance Materials Inc.

260 Hudson River Rd.

Waterford, NY 12188 US

800-295-2392 | 614-986-2495

momentive.com

IS THIS YOUR COMPANY?

As Seen On Plastics Technology

Momentive Performance Materials Inc. Supplies the Following Products

- Abrasion Resistant Coatings

- Adhesion Promoters (for Inks, Coatings)

- Adhesives for Plastics

- Air Release Agents

- Antiblocking Agents

- Antifog Coatings

- Antifogging Agents

- Cooling-water Treatment Chemicals

- Decorative Coatings

- Desiccant Additives

- Desiccant for Dryers

- Ethylene Vinyl Acetate (EVA)

- Ethylene Vinyl Alcohol (EVOH)

- Fillers--Microspheres (Hollow or Solid)

- Fillers--Mineral or Other Inorganic Type

- Fillers--Organic Type

- Flame Retardant Concentrates

- Flame Retardants/Smoke Suppressants

- Flame-resistant Coatings

- Impact Modifiers

- Lubricants

- Polyarylsulfone

- Polyetheretheketone (PEEK), Polyetherketone (PEK) and Other Polyketones

- Processing Aids--Mineral/Inorganic Type

- Processing Aids--Other Organic Types

- Processing Aids--Polymeric Type

- Release Agents--External (Spray or Wipe-on)

- Release Agents--Internal (Additive Type)

- Slip Agents

- Surfactants

- UV Stabilizer Concentrates

- UV-resistant Coatings

- Viscosity Depressants

Editorial, News, and Products

-

IMM Cells Display Communications, Energy Measurement and Energy Recovery

NPE2024: Wittmann will feature five injection molding machines incorporating its range of robotics and auxiliaries, with all products employing industry 4.0 communications, energy measurement and a brand-new red color.

-

Partnership Augments LSR Molding Simulation

SIGMA Engineering and Momentive Performance Materials announced a cooperation to optimize material data for silicone elastomers to make LSR molding simulation more reliable.

-

LSRs Developed for Alternative Drive Concepts

Momentive’s newly developed NevSil LSRs boast low curing temperatures.

-

Advanced Hardcoat Technologies for Automotive

Momentive’s SilFort technology geared to auto exterior applications.

-

Materials: New Self-Bonding LSR for Overmolding onto PC, PBT

Primerless adhesion of Momentive’s new LSR to PC and polyesters will be demonstrated at K 2019.

-

Injection Molding: New Software Shares Simulation Results Among Development Partners

New SigmaInteract software from Sigma Engineering helps different departments or project partners share simulation results.

-

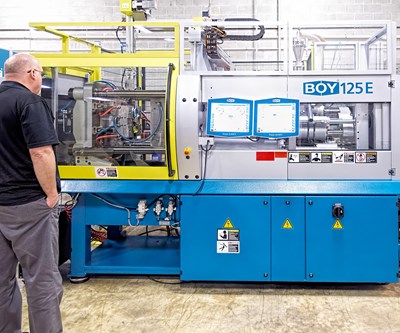

New, Largest Boy Machine Arrives in U.S.

Open house displays first model of Boy 125 E to hit our shores.

-

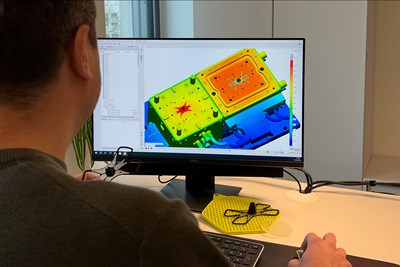

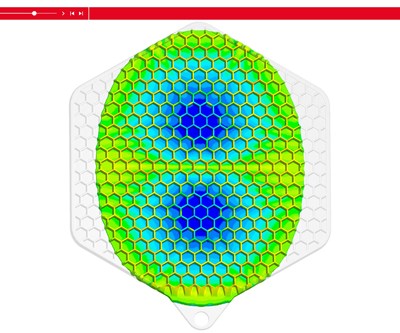

Autonomous Optimization Proves Its Worth in LSR Molding

Sigmasoft Autonomous Optimization automatically ran and analyzed 60 simulations to find the best way to mold a challenging LSR part.

-

Materials: Self-Bonding LSR Optimizes Overmolding with Specialty Copolyester

Momentive’s new LSR series enables overmolding with Eastman’s Tritan in a single-step process.

-

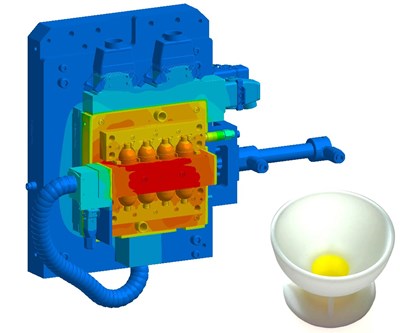

Two-Color LSR Molding Fine-Tuned with Flow Simulation

“Virtual Molding” simulation can model all aspects of LSR molding, even with two colors.

-

LSR & TPE Summit Highlights Trends And New Materials

Among them: an LSR for 3D printing and low-VOC TPEs for auto interiors.

-

News in LSR Molding at K 2016

Two-color molding with one injection barrel and pumping system.

-

K 2016 Preview: Injection Molding

Adapting injection molding to the concept of Industry 4.0 is gaining momentum. At this show you’ll see that the interconnected, integrated “factory of the future” is almost here.

-

New Materials Shine Bright In Growing LED Market

Rapid expansion of LED technology has spurred development of new formulations for a wide range of lighting components. Here are examples of activity in this fast-moving field.

-

LSR Developments in LEDs for Automotive and Street Lighting

LSR’s resistance to UV light and high temperatures allow direct contact to LED, while low injection pressure allows overmolding of sensitive parts.

-

Simulation Meets Reality: Physical & Virtual Molding of LSR

Growing sophistication in simulating the molding performance of LSR is evident in the case of this exceedingly complex part. Actual molding trials validated the predictions of simulated ‘virtual molding.’

-

What Customers Actually 'Need' When They 'Want' Certain Material Properties

Despite the fact that material specification in a part drawing will literally make or break a component, this key attribute is often treated like an afterthought, if addressed at all.

-

Materials at NPE: New Solutions to Enhance Processing, Performance, Sustainability & Cost

There was no shortage of new thermoplastics and additives covering the full range of end-use applications.

-

Fiber-Reinforced & Low-Volatility LSRs Unveiled

At NPE2015, Momentive launches advancements in fiber-reinforced and low-volatility LSRs.

-

Clearly a Contender

LSR Vies for New Applications in Automotive, Lighting, Healthcare, and More.

-

Injection Molding at K 2013: Doing More with Less

More productivity with less energy consumption and capital investment; more operations in the machine or manufacturing cell with less time, labor, energy, and capital—these were the common themes of injection molding exhibits at October’s K 2013 show.

-

Headlines from the K 2013 Show

Here’s just a taste of the innovations on display, a selection of the top headlines not covered in our September show preview.

-

K 2013 Preview: Materials & Additives

The K 2013 show will present a broad range of engineered plastics materials, including thermoplastic composites, as well as additives. Automotive and electronic applications will be the main targets, as well as medical, packaging, lighting, and construction.

-

New Machines & Processes for Medical, Auto, Packaging, Electronics

Engel’s technical symposium in June attracted 2700 visitors from 35 countries to two days of technical presentations and 18 injection molding exhibits at the company’s plant in St.

-

UV Cure Solves LSR Processing Challenges

Extended cure times for thick parts and temperature sensitivity of pharmaceutical additives are two challenges for silicone molding and extrusion that can be overcome with new low-temperature UV curing technology.

-

Additives: Three Trends to Track

Additives that render plastic compounds antistatic or electrically and/or thermally conductive are in hot demand.

-

Refine, Redesign, Retool: Re-engineering as a Business Model

It’s an unusual business model: “We take existing products or manufacturing processes and try to make them better.

-

Global Warming: New Challenge for Polyurethanes?

‘Zero-ODP’ is no longer enough. Now, PUR foamers are being asked to consider blowing agents with ‘low-GWP’ (global warming potential). Another environmental push is to expand use of bio-based polyols in rigid and flexible foams. Both were key topics at this year’s PUR conference.

-

Polyurethanes: Bio-Based Materials Capture Attention

The hot topic at this year’s PUR conference was rigid and flexible foams with increased biobased content. There was also news in one-component cast elastomers, surfactants, and TPUs.

-

Auto Glazing: Film, Coinjection & Coating Technologies Advance

Hard-surfacing options for molded plastic glazing now include plasma instead of wet coatings–and replacing coatings altogether with in-mold film lamination or multi-layer coinjection.

.png;maxWidth=300;quality=90)