3111 Park Dr.

Traverse City, MI 49686 US

231-947-3111

rjginc.com

IS THIS YOUR COMPANY?

As Seen On Plastics Technology

RJG Supplies the Following Products

- Closed-loop Process Control Systems

- Consultants - Design, Manufacturing, Purchasing

- Flow Monitoring/Control Devices (for Liquids)

- Machine Monitoring/Alarm Systems

- Motion or Position Controls

- Pressure Controllers, Monitors

- Pressure Sensors, Transducers

- Recording Instruments

- Scheduling, MRP, Production and Inventory Management Systems

- Sequence Logic Controls

- SPC, SQC Systems

- Training Programs in Plastics

- Troubleshooting, Problem Solving Systems

Trade Names Offered by RJG

Editorial, News, and Products

-

AI Integrated Into Injection Molding Process Control

RJG has augmented its CoPilot process control with artificial intelligence (AI) trained on in-house data gleaned from its network of training labs.

-

Free, Assisted Data Transfer for Injection Molding Monitoring and Control Platform

For a limited time and free of charge, RJG will help users of its eDART platform transfer data to its CoPilot system using a new data migration tool.

-

Atop the Plastics Pyramid

Allegheny Performance Plastics specializes in molding parts from high-temperature resins for demanding applications as part of its mission to take on jobs ‘no one else does.’

-

How Important is Minimizing Residence Time in Injection Molding?

Does a focus on the concept of “minimum residence time” distract attention from areas of injection molding that have more of a direct impact on melt quality?

-

Wittmann Delivers Injection Molding Workcell to Alabama Community College

Southern Union State Community College (SUSCC) installed the Wittmann SmartPower120 molding machine with an integrated robot, temperature control unit (TCU) and dryer to support its plastics education program.

-

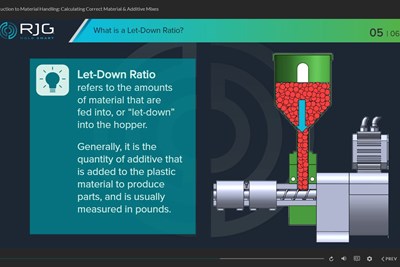

Learn Fundamentals of Materials Handling in Self-Paced Online Course

Learn about equipment, procedures and maintenance for material handling related to injection molding.

-

Fast, Easy Six-Axis Robot Integration Created by a Molder for Molders

Custom injection molder Noble Plastics has done its own six-axis robot integration with several brands of injection machines for over 20 years. Now it’s offering a turnkey service with what’s said to be unmatched speed, affordability and ease of implementation.

-

RJG Adds LS Mtron Molding Machine To Training Facility in North Carolina

The all-electric WIZ-55E was installed at RJG’s new training facility located on the Rowan-Cabarrus Community College (RCCC) campus in Kannapolis.

-

Matrix Tool: Welcome to the Family

In its 50th year, Matrix Tool applies moldmaking and injection molding expertise, plus a long family heritage, to high-precision jobs that many would deem impossible.

-

New Graph Interpretation Course for Injection Molding

RJG’s newest training course—Graph Interpretation for Injection Molding— introduces the principles of Decoupled Molding and the cavity pressure curves associated with such processes.

-

2022 Top Shops Benchmarking Survey: Cost Conquerors

Higher costs for materials, wages, utilities and more, coupled with delivery difficulties for both incoming supplies and outgoing production, posed unique challenges to 2022’s class of Top Shops.

-

Global Show, Global Training

Visitors to RJG’s K 2022 booth can watch training segments from each of its global offices in the RJG Theater, as well as get hands-on demos of its CoPilot process control and Hub networking devices.

-

Stop Controlling Your Injection Molding Process with Machine-Only Settings

Monitor and record process outputs instead of the machine setpoints to ensure a validated process regardless of any machine deterioration, viscosity changes or other alterations.

-

RJG Appoints New CEO

Rob Nugent will take the reins from Dale Westerman, who is stepping away after 24 years at RJG.

-

How to Set Up Mold Protect on Your Injection Machine

Set the start position for mold protect where anything in the mold could be subject to damage.

-

Plastikos Wins Inaugural RJG Mold Smart Award

RJG named the medical molder as the first North American winner of the new award for its use of RJG training and technology, with YanFeng and Stoneridge recognized for Latin American and Asia, respectively.

-

RJG Releases Online Injection Molding Training Course

Technology and training supplier RJG has introduced the new online, self-paced Essentials of Injection Molding eLearning course for interactive training that can happen anywhere.

-

Injection Molding Process Control to Add Valve-Gate Control

RJG’s CoPilot System will add the capability to control hot runner valve gates.

-

Going for the Green vs. Getting in the Hole

Too often when designing a tool or establishing a process, molders go for the hole in one when they only need to aim for the green.

-

Injection Molding Networking Software Adds Simulation Support

RJG’s Hub now supports Moldex 3D and Autodesk’s Moldflow/Insight injection molding simulation software.

-

Total Transparency at Trademark Plastics

Trademark Plastics’ latest investment won’t let it see the future, but by giving it vision inside parts, the new CT scanner represents a more transparent tomorrow for its validation work.

-

The Difference Between Knit and Meld Lines--and Why It Matters

In many part designs, flow fronts will inevitably be split, but how and where they come back together is hugely important to the molded part’s finished strength.

-

Injection Molding Networking Platform Adds Mold Transfer Software

RJG says the new Mold Transfer software allows users to generate machine-specific setup sheets, recommend compatible machines and more.

-

RJG Consolidates Southeast Training Facilities in North Carolina

RJG is consolidating its Gibsonville, N.C. and Woodstock, Ga. training facilities to Rowan-Cabarrus Community College’s (RCCC) campus in Kannapolis, North Carolina.

-

Slowed—but not Stopped—by the Pandemic, Custom Molder Catches Up with Its Plans for Growth

No one’s 2020 plans survived the pandemic unscathed, including those of Plastic Molding Technology Inc. But this injection molder’s vision of how it would continue to thrive as it approaches its fifth decade was simply deferred, not denied.

-

Process Monitoring or Production Monitoring—Why Not Both?

Molders looking to both monitor an injection molding process effectively and manage production can definitely do both with tools available today, but the question is how best to tackle these twin challenges.

-

Keeping It in the Family: Medical Molder Grows with Second Generation at the Helm

Evolving from a two-man moldmaking company in a rented garage to three unique businesses, including a new medical injection molding unit, with 185 full-time employees, Micro Mold, Plastikos and Plastikos Medical enter their fourth decade family-led and poised for growth.

-

Five Questions to Ask Before Instrumenting a Mold

There are plenty of good reasons for putting sensors in a mold—but what is most important for your application? Answer that first, before considering what type of sensor to use and where to locate it.

-

RJG Expands Online Training Offerings

Five new course cover tool launch, part design, mold design, machine performance and systematic molding for LSR.

-

Fast, Simple, Low-Cost Method Unveils ‘True’ Melt Temperature

Long a mystery to injection molders, actual temperature of melt entering the mold is said to be revealed by an easy procedure that is repeatable and takes less than a minute.

-

Injection Molding: RJG Adds Virtual Training, Consultation

In response to the Covid-19 crisis, RJG has launched online interactive training, free live webinars and personalized remote consultation services.

-

Molder Gets Into World-Class Shape

Shape Corp.’s Grand Haven, Mich., facility challenges itself and its employees to run leaner, pushing productivity and efficiency to new limits.

-

RJG Opens New Training Lab in Germany

RJG Germany GmbH opened its new training lab on Jan. 1, 2020, including a classroom that seats up to 20 students and a fully-equipped lab for hands-on experience.

-

HRSFlow and RJG Pair Technologies for Advanced Process Control

By pairing HRS Flow’s servo-driven FLEXflow hot runner with RJG’s sensors and eDART controller, the collaborators say they’re able to sequence mold filling based on what’s actually happening in the tool vs. time or screw position.

-

Molding Better Molders, One Class at a Time

Founded by and named for Rod Groleau, RJG grew out of an appreciation for two burgeoning needs of the plastics industry: training to help people better understand the molding process and equipment to let them actually see what’s happening inside that process.

-

How Second-Stage Injection Speed Influences Your Process

As an injection molder, you’re familiar with first-stage fill-speed profiles and second-stage pressure settings, but have you considered the function of second-stage speed, or “hold flow”? Here’s what it does and how it affects your molded part.

-

RJG Partners with a Nebraska Community College on Injection Molding Training Lab

RJG and other partners are contributing to new plastics training lab at Central Community College in Columbus, Neb.

-

RJG Helps Bring Molding Training to Nebraska College

Central Community College (CCC) to embed RJG education into curriculum when new training lab is completed in the beginning of 2020.

-

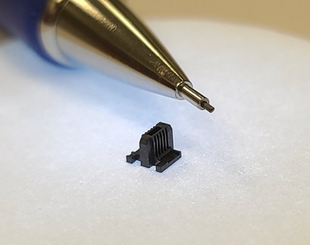

Injection Molding: Smallest Cavity-Pressure Sensor With Higher Force Rating

Indirect sensor for high cavitation can be used with larger ejector pins.

-

To Succeed in Manufacturing, Focus on Your People First

It’s not easy being a custom injection molder in the NYC metro area. For Natech Plastics, the key is developing employees’ skills and commitment.

-

How to Manage Pressure Loss in Injection Molding

Achieving a process window wide enough to ensure consistent part quality depends on achieving sufficient pressure at end of fill.

-

Filling a Precision Molding Niche in Mexico

Originally opened and dedicated by Mexican President Vicente Fox in 2006, GW Plastics has expanded the business and capabilities of its facility in Querétaro, adapting and evolving along with that country’s thriving injection molding market.

-

Digital Manufacturing: Two Medical Molders Embrace Industry 4.0

‘Digitalization’ and ‘connectivity’ are loaded terms—shorthand for a whole new way of doing business. It can’t be accomplished in one go. But two Midwest molders in the sensitive medical field are already feeling the benefits of their initial steps in that direction.

-

Fast or Slow: What’s Better for Injection Molding Fill Times?

If you’re talking zombies or injection molding fill time, there is a debate to be had about fast vs. slow.

-

Up to Snuff on Scientific Molding? Then it’s Time to Mold ‘Systematically’

Scientific molding is centered around learning about key molding principles and theories. The strategic application of those principles and theories is what’s known as systematic molding.

-

‘Smart Data’: The Rise of the ‘Dashboards’

For North American plastics processors, NPE2018 offered the broadest exposure yet to the bundle of trends and technologies known as Industry 4.0 or the Industrial Internet of Things (IIOT).

-

Injection Molding: New Source of Moldflow Training

RJG Inc. has added Moldflow training to its course roster.

-

RJG Demos of Hardware & Software Daily

In its booth and at separate presentations, RJG will demonstrate its training and process monitoring offerings at NPE2018.

-

Injection Molding: New eLearning Course on ‘Math for Molders’

RJG launches first online eLearning course for injection molders.

-

New Tech Center Shows Off New Injection Presses

Facility features a variety of machines from Yizumi-HPM for the U.S. market.

-

RJG Introduces Low-Cost Part Design Analysis

New service provides quick and affordable analysis early in the design phase.

-

Variotherm Molding Can Double Flow Length, Cut Cavity Pressure By 70%

RocTool’s year-old HD Plastics Materials Database further expanded.

-

RJG Opens New Injection Molding Training Facility in NC

RJG, Inc. is working alongside ZAG Equipment Sales to open a new training center for injection molding.

-

Custom Molder Expands in ‘Leaps of Faith’

Who would embark on an $8.8 million plant expansion without new orders in hand? Someone who knows his customers very well.

-

So How Fast Can You Change a Mold?

A contest next month at a U.K. trade show will crown one molder king of the quick-change artists.

-

RJG Presents 2015 Training Excellence Awards

Moldmaker, molder acknowledged for their commitment to training.

-

For This Molder, Less Paper + More Data=Higher Productivity

At Tessy Plastics, going paperless means more than idle printers and fewer orders for three-ring binders.

-

New Sensor Tech Monitors State of the Melt During Molding

Detect ‘true’ melt temperature, viscosity variations, melt density, and much more, throughout the molding cycle.

-

‘There are no unskilled jobs here anymore’

That observation comes from Mary Ann Cervinka, HR manager Arrow Gear, and is found Accenture’s 2014 Manufacturing Skills and Training Study, appropriately entitled, “Out of Inventory: Skills Shortage Threatens Growth for U.S. Manufacturing.”

-

Machinery & Robot Developments at Wittmann Battenfeld

Open house celebrates expanded U.S. headquarters & showcases innovations.

-

Winzeler Gear Thrives With a Little Help from Its Friends

Strategic partnerships give a small molder the technical clout of a much bigger firm.

-

Wittmann Battenfeld Hosts Live Show

Open house to celebrate the expanded U.S. headquarters showcases innovations.

-

MRPC Takes ‘Holistic’ Approach To Scientific Molding

Last year this family-owned molder made a major commitment to Scientific Molding by starting a training process involving all employees.

-

EVCO Plastics at 50: Still Thinking Big

In its first half-century, EVCO Plastics has grown from one half-ounce injection machine in a basement to a $130 million company with 148 presses and 900 employees at nine plants in the U.S., Mexico, and China.

-

Technology, Creativity, and Fun: The Noble Plastics Recipe

Most people find jobs within companies thatahave an established corporate mission and business culture.

-

Automation & Waste Reduction: A Medical Molder's Efficiency

Vision Technical Molding in Manchester, Conn., doesn’t believe in standing still.

-

Micro Molder & Mold Maker Succeeds by Specializing

How small is small? How small is micro? How about parts weighing as little as 0.00012 g and measuring no more than 0.038 in. (1 mm) long?

-

Refine, Redesign, Retool: Re-engineering as a Business Model

It’s an unusual business model: “We take existing products or manufacturing processes and try to make them better.

-

Unbalanced? No Shortage of Ways to Fix Uneven Filling of Multi-Cavity Molds

The accepted ground rule for balancing melt flow in multi-cavity injection molds is to achieve equal flow distance from the injection point to each cavity.

-

Foiling Flow Imbalances In Multi-Cavity Tools

In multi-cavity molding, attaining uniform and balanced flow of material to each cavity is a frequent challenge.

-

One Method Can Diagnose Six Main Causes of Bad Parts

World-class lean-manufacturing principles and total quality programs will not necessarily prevent an injection molder from making occasional bad or suspect parts.

-

A Custom Molder Takes the Next Step

The question John Winzeler keeps asking is, “How do you take the next step?” In the last two decades, he has transformed the Chicago metal-stamping company he inherited from his father into a high-tech specialty molding business focused only on plastic gears.

-

What to See at NPE 2006: Injection Molding

Energy-saving all-electric machines will continue to be a big draw at NPE, where new designs or upgraded models will be found in virtually every press maker’s booth.

-

Information Is Power

It’s the power to run your plant and machines better and more profitably. Today’s process and production monitoring systems put that information in the palm of your hand.

-

Small Molder Builds a High-Tech Showplace

How does a small injection molding company position itself to compete with much larger, technically sophisticated rivals?