Sumitomo (SHI) Demag

410 Horizon Dr.

Ste. 200

Suwanee, GA 30024 US

678-892-7900

sumitomo-shi-demag.us

IS THIS YOUR COMPANY?

As Seen On Plastics Technology

Sumitomo (SHI) Demag Supplies the Following Products

- Injection Molding Machines

Editorial, News, and Products

-

Moldmaker Showcases Molding Equipment for LSR, Injection Molds

NPE2024: M.R. Mold showcases its proprietary line of products for liquid silicone rubber (LSR) and plastic injection molds alongside four industry partners.

-

All-Electric IMM Advances for Packaging, Medical and LSR

NPE2024: Sumitomo SHI Demag’s show focus will be on application of all-electric injection molding machine technology for a variety of markets and components.

-

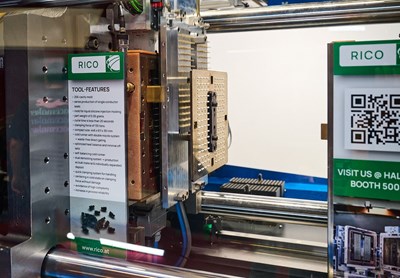

LSR Advances in Dispensing, Tooling and Automation

At Fakuma 2023, Sumitomo (SHI) Demag’s LSR injection molding machines showcased advances from itself and partners Reinhardt-Technik, Rico and Sepro.

-

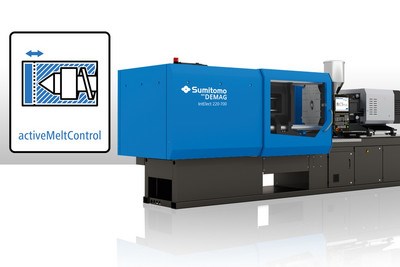

Adaptive, Automatic Process Control for Injection Molding

Sumitomo (SHI) Demag says its activeMeltControl for all new IntElect 2 machines can automatically compensate for shot-weight variations.

-

Fakuma 2023: High-Speed Pipette Tip Molding

Sumitomo (SHI) Demag, Hekuma and Schöttli partnered on production cell molding pipette tips from a 32-cavity mold in a cycle of 4.5 seconds.

-

Fakuma 2023: Sepro Introduces Its Fastest Top-Entry Robot, Integrative Controller

The concept ThundeRbot enters and exits the mold with parts in 0.79 second, while the Sepro Visual+ controls all the peripheral equipment in the show cell.

-

Sumitomo (SHI) Demag to Double Injection Molding Machine Production in China

The company broke ground on a new 43,000-ft2 production hall in Ningbo to fulfill rising demand for larger presses up to 1500 tons.

-

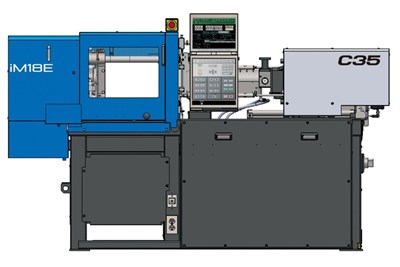

Compact Hybrid Injection Molding Machine Launched

Sumitomo Heavy Industries Ltd. (SHI) has introduced the iM18E, promising the smallest footprint in 20-ton machines.

-

K 2022: LSR Cell Makes Four Different Lids With Each Cycle

Elmet, Sumitomo (SHI) Demag, Shin-Etsu and Mettler Toledo collaborated on the cell which molds, weighs and laser marks silicone covers for beverage and food cans.

-

K 2022 Preview: Injection Molding Closes the Circle, Digitally

Because the market requires sustainability—and important component of which is the circular economy—and sustainability requires digitization, all three will be major themes at injection molding booths at K 2022.

-

Beacon MedTech Solutions Increases Injection Molding Capacity

The company’s Leominster, Mass. facility has recently installed two new Sumitomo (SHI) Demag machines with plans to add an undisclosed number more in the first half of 2022.

-

Westminster Tool Partners with Sumitomo (SHI) Demag

The Connecticut moldmaker added a new all-electric Sumitomo (SHI) Demag press, boosting its mold qualification capacity and giving the machine maker a New England outpost for sales and training.

-

Why Put Flow Simulation on an Injection Machine?

This emerging technology sounds promising, but its practical benefits have yet to be demonstrated clearly.

-

Fakuma: Sumitomo (SHI) Demag Emphasizes All-Electrics and Permanent Machine Status Condition Monitoring

The company will feature three all-electric injection molding machines from its IntElect series, plus one from its El-Exis SP packaging range at the show in Friedrichshafen, Germany.

-

Industry 4.0 Communication Standard Adds Hot Runners, LSR Dosing

EUROMAP and the OPC Foundation’s joint working group issued a standardized data exchange communication protocol for hot runner devices and liquid silicone rubber dosing systems.

-

Diversified Plastics Installs Six Vertical Injection Molding Machines

The company added all-electric Sumitomo (SHI) Demag, Niigata and Nissei molding machines to its Minnesota facility in support of medical device customers and other manufacturers.

-

20 Good Things to Come Out of 2020—Part 4

Good news was there if you knew where to look for it—in the pages of Plastics Technology magazine or right here on our website. Here’s a review of headlines you can feel good about.

-

Lights Out, Pristine Production In

The numbers beggar belief and the business belies description—Medical Components of America has six full-time employees, six injection machines and lights-out production that’s gone five years without shipping a bad part or missing a delivery.

-

Decorating, Printing: New Decorating Technologies for Tubes and Injection Molding at K 2019

Digital metallic and multicolor decorating of squeeze tubes, combination hot-stamping and four-color printing machine, and large-area injection molding IMD were some of the news from Kurz at K 2019.

-

Injection Molding: Faster, Smarter, More Efficient Machines Tackle Sustainable Molding at K 2019

Blazing speed plus shrinking energy consumption supported the “green” theme at the big show. Smarter controls and growing connectivity were another key focus.

-

Simulation Is Making Injection Machines Smarter

Engel’s simlink will refine offline simulation with results from actual molding and use Engel’s machine data to constrain simulation within the actual machine’s capabilities.

-

Injection Molding: Artificial Intelligence Predicts Part Quality

AI software “learns” via DOE the influence of process variables on part quality and applies that “learning” to make good/bad part determination in production.

-

Sumitomo Demag Adds two New Tech Centers

New training and demo centers in Illinois and California will help molders keep up with technical developments as they happen.

-

Molder Adopts ‘Semi-Smart’ Automation

R&D Plastics finds new and more sophisticated ways to use robots.

-

Next-Generation Technologies Benefit Demand for LCPs

‘5G’ and ‘3D printing’ are key drivers in growing demand for LCPs according to FactMR study.

-

Injection Molding: New Automation Approach for Medical Pipette Tips

Hekuma’s fast and flexible new-generation system will be demonstrated at K 2019.

-

K 2019 Preview: Injection Molding Goes for the ‘Green’

‘Circular Economy’ joins Industry 4.0 as common themes of injection molding exhibits in Düsseldorf.

-

Materials: LCPs Prove to be Material of Choice for Fine-Pitch Electrical Connectors

Two new high-flow, low-warpage LCP formulations from Sumitomo Chemical are key to achieving today’s thinner, smaller, higher-density interconnects.

-

Sumitomo Demag Moves & Expands

Georgia HQ doubles in size at new location.

-

Filling a Precision Molding Niche in Mexico

Originally opened and dedicated by Mexican President Vicente Fox in 2006, GW Plastics has expanded the business and capabilities of its facility in Querétaro, adapting and evolving along with that country’s thriving injection molding market.

-

Injection Molding: Faster Robots & Cobots

Sepro introduces S5-25 Speed Cartesian model and Seprobot collaborative solution for standard robots.

-

Digital Manufacturing: Two Medical Molders Embrace Industry 4.0

‘Digitalization’ and ‘connectivity’ are loaded terms—shorthand for a whole new way of doing business. It can’t be accomplished in one go. But two Midwest molders in the sensitive medical field are already feeling the benefits of their initial steps in that direction.

-

Headlines from Fakuma 2018

Integrating a special low-pressure process into machine controls; novel shop-floor quality-inspection technology; MES systems from machine and controls vendors; and sophisticated in-mold decorating.

-

Injection Molding: High-Speed All-Electric Press Line

Designed for packaging with cycle times of 3 to 10 sec.

-

NPE2018 Tooling: Molds Join the Industry 4.0 Conversation

At NPE2018, multiple companies displayed mold monitors that would allow the tool in an injection molding cell to “talk” to other equipment and remote computers.

-

NPE Wrap-Up: News in Primary Machinery, Part 1

Rounding up details from the Big Show not previously reported in all our other coverage, here’s more news in injection and blow molding, extrusion and compounding. Next month, we’ll conclude with recycling/scrap reclaim, robots, tooling, auxiliary equipment, materials and additives.

-

NPE2018 New Technology Focus: Dazzlingly High-Speed Packaging Production

Several machine suppliers are injection molding caps and thin-wall cups in as fast as 2-sec cycles.

-

NPE2018 New Technology Focus: Micromolding is Big

Micromolding is a growing force in medical, electronics and micromechanical parts.

-

Sumitomo’s Theme: Productivity + Flexibility + Reliability

Sumitomo Demag aims to demonstrate a combination of speed, flexibility, proprietary technologies, and automation with six machine cells running at NPE2018.

-

Global Player in Robots Puts More of Its Chips on North America

Sepro has global distribution but North America is its biggest growth market. It is manufacturing here for the first time.

-

NPE2018 New Technology Focus: Healthy Interest in Medical

Medical molding is a big presence at NPE.

-

NPE2018 New Technology Focus: The ‘4.0’ Revolution

Injection and blow molding and robot suppliers are making Industry 4.0 the most prevalent theme of the show.

-

It’s All About Speed at Sumitomo (SHI) Demag

Sumitomo Demag all-electric toggles and hybrid injection molding machines are molding high-speed medical and packaging applications.

-

Sepro Features Its First ‘Made-in-America’ Robot

Sepro America is now building large robots in the U.S., including this 7X-45 five-axis unit.

-

New Physical Foaming Process Debuts at Fakuma

Pellets are impregnated with CO2 gas in a sealed chamber, which need not be mounted on the injection machine.

-

Injection Molding: Industry 4.0 Advances at Fakuma 2017

At October’s Fakuma fair in Germany, several injection machine suppliers will showcase their progress toward Industry 4.0 connectivity.

-

Advances in Molding, 3D Printing At Arburg ‘Technology Days’

Over 6700 visitors saw more than 50 working machinery exhibits highlighting automation, connectivity, and sophisticated processing.

-

Augmented Auxiliaries At K 2016

Incremental improvements to existing technologies combined with altogether new advances at the giant show.

-

K 2016 Injection Molding: Rapid Pace of Development

Servo drives dominate. Other trends include multitouch screens, adding materials data to process controls, and Industry 4.0 connectivity.

-

K 2016 Preview: Injection Molding

Adapting injection molding to the concept of Industry 4.0 is gaining momentum. At this show you’ll see that the interconnected, integrated “factory of the future” is almost here.

-

Two-Shot Molding Helps Make Reshoring Cost-Effective

With help from labor-saving technology, a maker of children’s dinnerware finds a ‘Made in USA’ solution to quality & delivery issues.

-

Beefier All-Electric Machines With Enhanced Control Features

Presses designed to dismiss the perception that all-electrics can’t handle larger, heavier molds.

-

Rethinking the Injection Screw: Is It a Trend?

Renowned screw designer Robert F. Dray wrote to me recently, lamenting that injection molding screw design has not received the kind of attention that the extrusion industry has paid to perfecting this fundamental processing component.

-

INJECTION MOLDING: New Electric Press Series Geared for Mid-Sized Molding

Highly spec'ed presses handle bigger, heavier molds for mid-sized automotive and other parts.

-

Ten Intriguing Injection Molding Technologies of 2015

I know I’m leaving myself wide open on this one. I was asked, “What are the 10 most interesting injection molding technologies of 2015?” I should have pleaded eggnog hangover and politely declined.

-

Highlights of Fakuma 2015

A selection of the hottest news and molding trends at this “little brother” to the K Show.

-

Have You Ever Seen Faster?

Four PP cups in 1.55 seconds!

-

Lightweight Composites & Superfast Container Molding at Fakuma Show

Overmolded UD tapes replace organosheet with major weight savings. And 4 PP cups molded in 1.55 sec.

-

A Very Small World: Micromolding at Makuta

Makuta Technics sweats the tiny details so it can run ‘lights out’ most of the day.

-

Betting on Biopolymers

A new injection molding business is focused 100% on compostable, plant-based polymers.

-

INJECTION MOLDING AT NPE: Presses, Robots & Cell Automation

Everything molders need to compete in markets from automotive to medical was on display in Orlando. Besides a huge number of new machine models, there was emphasis on cell integration and automation.

-

News Highlights from NPE2015

Here’s a first look at new technology in materials, auxiliaries, and all types of processes.

-

INJECTION MOLDING AT NPE: Molding Exhibits Show Off Cell Integration with Multiple Processes & Operations

If you’re interested in lightweight composites, IML, LSR, multi-shot, inmold assembly, barrier coinjection, micromolding, variotherm molding, foams, energy-saving presses, robots, hot runners, and tooling—they’re all here in force.

-

Key Themes from the Fakuma Show

Servo-hydraulics, servo sprue pickers, electronic water-flow monitoring/control, and exotic multi-process cells were the headliners in Friedrichshafen.

-

Three Themes at Fakuma Show

Servo hydraulics are becoming standard; servo pickers proliferate; water flow monitoring and control are new focus.

-

Injection Molding at K 2013: Doing More with Less

More productivity with less energy consumption and capital investment; more operations in the machine or manufacturing cell with less time, labor, energy, and capital—these were the common themes of injection molding exhibits at October’s K 2013 show.

-

K 2013 Preview: Injection Molding

Next month’s mammoth triennial plastics show in Düsseldorf, Germany, challenges injection molding machine builders to demonstrate technological leadership in addressing the needs of the marketplace.

-

Extreme Molding’s Mantra: ‘Find Your Niche and Stick to It’

For a small custom injection molder competing in today’s global market, Lynn Momrow-Zielinski has two pieces of advice: 1) Develop a business plan and stick to it. 2) Find a technical and/or market niche and stick to that, too.

-

Technology, Creativity, and Fun: The Noble Plastics Recipe

Most people find jobs within companies thatahave an established corporate mission and business culture.

-

New Injection Screw Breaks the Rules, But Fixes Many Molding Defects

“Revolutionary” screw design turns conventional plastication theory upside down.

-

NPE: New Machines Exhibit Sophisticated Molding Demos

More speed, more power, more precision, and more automated functions accomplished in and out of the mold. That’s exactly what injection machinery suppliers were offering at NPE2012.

-

Injection Molding: Speed, Automation & Integration

Hot buttons at the show will be multi-component molding, in-mold labeling/decorating (IML/IMD), in-mold assembly, medical molding, liquid silicone rubber (LSR), micro-molding, and high-speed packaging.

-

On-Site: This Currier Delivers

“We love to tell our story.” That’s one way Mike Cartner, CFO of Currier Plastics, defines what separates this family-owned custom processor from its competitors.

-

K 2010- Injection Molding New All-Electrics & Hybrids Balance Performance & Economy

The world’s largest plastics show, coming up next month in Dusseldorf, Germany, provides ample evidence of the growing sway of electric drive technology in injection molding.

-

On-Site: An ‘Empire’ Built on Scientific Molding

A U.S. custom injection molder that’s hiring?

-

Injection Molding at NPE 2003

Show goers will see an electric injection machine in nearly every press maker’s booth this year, and electric/hydraulic hybrids in several.

-

Hybrid Injection Clamps The Best of Both Worlds?

In between all-electric and hydraulic-powered injection machines, a new species of hybrid clamp has emerged. Advocates say it combines the best qualities of electric servos and hydraulics without their disadvantages.

-

New Presses at Fakuma Show Focus on Energy & Performance

Beltless direct-drive electric machines and upgraded electric/hydraulic hybrids were introduced at the 20th Fakuma trade exhibition in Friedrichshafen, Germany, last month.

-

NPE 2009 Wrap-Up: New Machinery for Injection Molding

New injection machinery at the show ranged from all-electric units for high-speed packaging or bioplastic processing to hybrid presses ready for the cleanroom. Other units highlighted multi-component molding with LSR and thermoplastics or super-compact presses for small parts. Several new machines targeted specific applications such as caps and closures, PET preforms, LSR, or integrated long-glass compounding.

-

NPE News in Injection Molding

If a better machine can help your company beat challenging economic conditions, you’ll probably find it at NPE. And finding it will be easier, thanks to our editors’ efforts to sift out of some 2000 exhibits the most significant news in injection and blow molding, extrusion, compounding, and thermoforming.

-

How IML ‘Cuts the Mustard’ in Germany

The lightweighting advantages of in-mold labeling in times of soaring resin costs are highlighted by the experience of Germany’s largest mustard maker.

-

Injection Molding LSR: Three 'M's of Innovation: Mega, Micro, and Multi

Liquid silicone rubber is breaking out of its niche into a broader array of applications, helped by new developments in materials, machinery, and processing. Larger parts, micro-parts, foams, and multi-color or multi-material combinations are key areas of innovation.

-

Small Molder Makes Big Parts

Some people might be tempted to lump all processors with annual sales under $10 million into the same category: shoot-and-ship makers of no-fuss products using straightforward processing.

-

Electric, Hydraulic, or Hybrid? What's the Right Injection Press for You?

If you were buying an injection molding machine 20 years ago, you had to decide between a toggle or fully hydraulic clamp and that was pretty much it.

-

NPE 2006 News Wrap-Up: Injection Molding

Advances in electric drive technology were evident in nearly every injection machine builder’s booth in Chicago.

-

All-Electric Plant Gets World-Class Results

In mid-2004, Delphi Connection Systems, part of Tier 1 automotive supplier Delphi Corp.’s Packard Electric operations, flipped the switch on a new 190,000-sq-ft, $58-million plant in Vienna Township, Ohio.

-

The Next Generation of Multi-Component Molding

Multi-shot and coinjection molding techniques are staking out new territory. Mach ines are getting larger and are combining more materials or colors in more sophisticated and imaginative ways.

-

K 2004 Wrap-Up on Injection Molding: Spotlight on Electric And Multi-Component Machines

Molders were treated to a trove of injection machinery introductions geared toward applications from micro-molding to packaging to large parts.

-

NPE News Wrap-Up: Injection Molding

Stress-free production of large car windows, in-mold painting, and an injection unit that applies pack and hold while accumulating the next shot were a few of the cutting-edge technologies on display.

-

Electric Machines and New Processes Catch Fire

The October show in Dusseldorf saw an onslaught of new all-electric and hybrid-electric presses, with modular designs, new clamping styles, and new sizes available from an ever-growing range of suppliers.

-

Injection Molding (K 2001 Preview)

All-electric machines will be one of the biggest themes in injection molding machinery at this year’s K show, where at least nine firms will bring out their first models.