Compounding

Teknor Apex Acquires Lanier Color, Expands Into PVC Colorants

Teknor broadens portfolio with PVC color concentrates and specialty compounds for building and construction.

Read MoreLeistritz Adds Post to Sales Team

Extrusion veteran joins machine builder as product manager for life science and specialty film applications

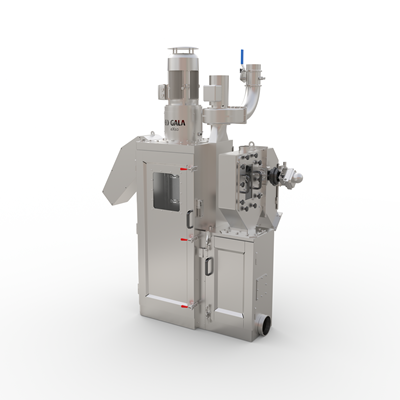

Read MoreCentrifugal Dryer for Underwater Pelletizing

Units designed to improve reliability, reduce changeover time and improve product quality.

Read MoreUse These Twin-Screw ‘Tools’ to Improve Quality of Your Color Pigment Dispersions

A twin-screw compounding extruder is a single piece of equipment divided into distinct unit operations. Thinking of each unit operation as part of a toolbox can help determine what can be added or improved to process best-quality color masterbatches.

Read MoreRibbon Blenders Now Come with Pressure-Feed Vessels

New option enables 100% discharge of the liquid component through a spray bar and into the blending zone, ensuring even mixing and consistent batches.

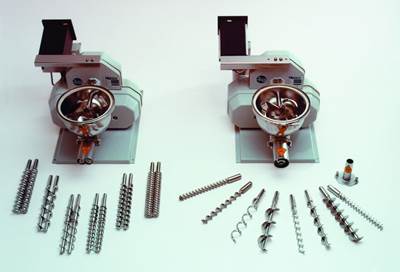

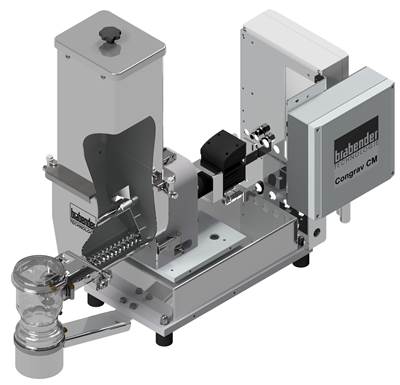

Read MoreModular Feeding System

Gearing units on both feeders to be easily and quickly changed and removed and replaced in just a few steps.

Read MoreENTEK Opens New Plant in Nevada

Builder of twin-screw compounding extruders says it needs extra space to meet demand.

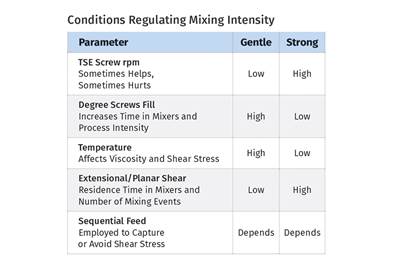

Read MoreTroubleshooting the ‘Mixing Experience’ in Corotating, Intermeshing Twin-Screw Extruders

The metering equipment, twin-screw extruder and downstream systems all must work in concert to control the properties of the final part and manage the process of mixing.

Read MoreEquitech Establishes Worldwide Extruder OEM Sales Program

Manufacturers of extruders, feeders, and other processing equipment can work with Equitech to integrated its technology into their control and process management systems.

Read More