Feeding & Blending

Fluff Feeder Offers Higher Film-Scrap Capacity, Better Reclaim Efficiency

Feeds granulated film scrap into a stream of virgin material and delivers the mix to extruder.

Read MoreBulk-Bag Discharger Has Two Flexible Screw Conveyors

A new Flexicon Bulk Bag Unloader with Dual Flexible Screw Conveyors feeds two downstream processes dust-free.

Read MoreHigh-Torque Twin & Novel Feeding System Debut for Compounding

ENTEK takes the wraps off three innovations aimed at increasing productivity.

Read MoreDust-Tight Batch-Weigh System

System integrates conveying and weighing for speed and accuracy.

Read MoreRotary Bridge Break Helps Dose Poor-Flowing Materials

Designed for largest gravimetric blenders, Maguire device helps accurately dose regrind, recyclate, and other bridge-prone ingredients.

Read MoreWeight-Loss Feeder Features Array of Unique Capabilities

Offers highly accurate and reliable feeding of a wide range of dry solids materials.

Read MoreDosing Software Packed with New Features

Also allows for remote access for installation and service.

Read MoreMaguire Buys Stake in O.A. Newton

Investment has the potential to expand the capabilities of Maguire in the bulk material handling phase of the process industries.

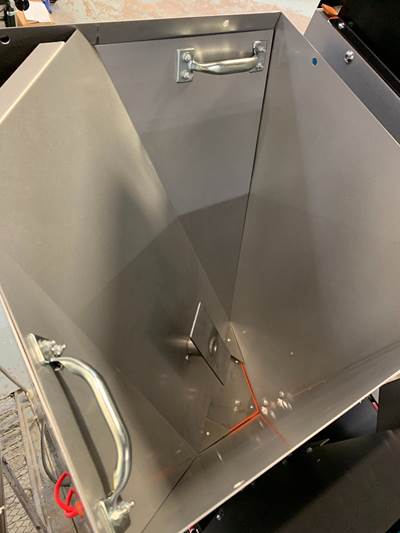

Read MoreSanitary Ribbon Blender with Bag-Unloading Station

Unit utilizes safety-limit switches that prevent operation of the agitator if any access ports are open or if the grating is removed.

Read More (2).jpg;maxWidth=970;quality=90)

(2).jpg;maxWidth=300;quality=90)

(1).jpg;maxWidth=970;quality=90)