Know-How

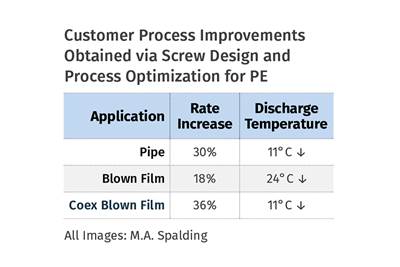

How Screw Design Can Boost Output of Single-Screw Extruders

Optimizing screw design for a lower discharge temperature has been shown to significantly increase output rate.

Read More21 Tips to Slash Energy Costs in Molding

This checklist can provide injection molders a good starting point on the path to reduced energy consumption and can generate some money savings on that journey.

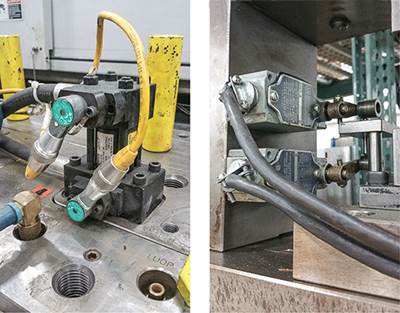

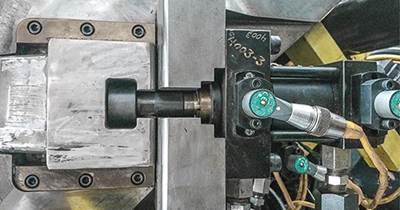

Read MoreThe Impact of Hydraulics on Tool Design, Practical Uses -- Part 2 of 2

Here are more tips on using hydraulically actuated devices on your tools.

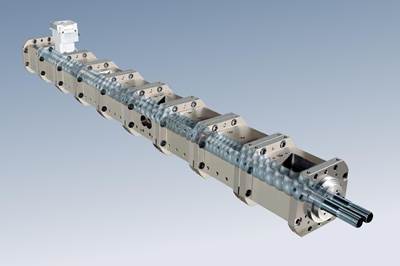

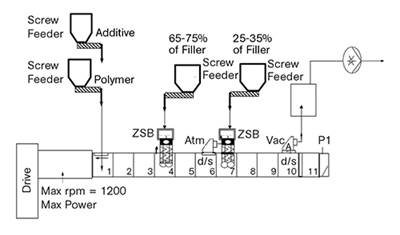

Read MoreHow to Configure Your Twin-Screw Barrel Layout

In twin-screw compounding, most engineers recognize the benefits of being able to configure screw elements. Here’s what you need to know about sequencing barrel sections.

Read MoreTracing the History of Polymeric Materials, Part 26: High-Performance Thermoplastics

The majority of the polymers that today we rely on for outstanding performance — such as polysulfone, polyethersulfone, polyphenylsulfone and PPS — were introduced in the period between 1965 and 1985. Here’s how they entered your toolbox of engineering of materials.

Read MoreThe Impact of Hydraulics on Tool Design -- Part 1 of 2

Get a better understanding of their use, proper sizing, and how the tool design and setup in the machine can impact failures in manufacturing.

Read MoreTroubleshooting Vent Flow Problems in Single-Screw Extruders

Vent flow can be a costly problem and a housekeeping nuisance. Here is some advice on how to eliminate it.

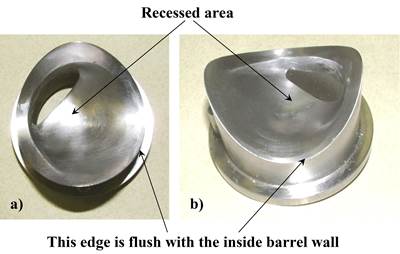

Read MoreImproving Twin-Screw Compounding of Reinforced Polyolefins

Compounders face a number of processing challenges when incorporating a high loading of low-bulk-density mineral filler into polyolefins. Here are some possible solutions.

Read MoreHow Important is Minimizing Residence Time in Injection Molding?

Does a focus on the concept of “minimum residence time” distract attention from areas of injection molding that have more of a direct impact on melt quality?

Read MoreHow to Select the Right Tool Steel for Mold Cavities

With cavity steel or alloy selection there are many variables that can dictate the best option.

Read More