Materials Know How

Imagine A World Where Polymers Were First

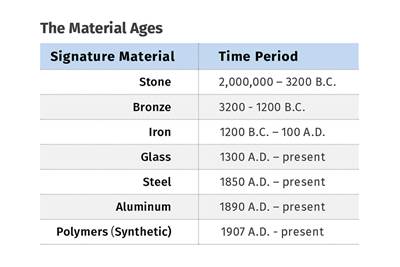

One reason for the disproportionate attention that plastics receive in the environmental conversation is that they are newcomers. Perhaps if we had been relying on them for thousands of years, we’d view them differently.

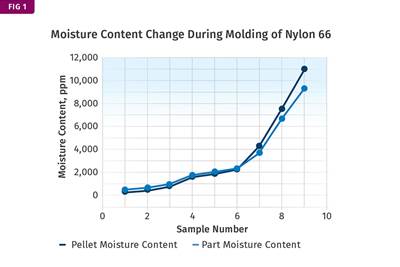

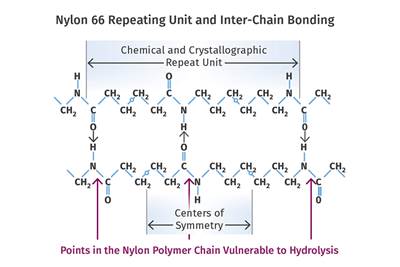

Read MoreWhat's the Allowable Moisture Content in Nylons? It Depends: Part 2

Operating within guidelines from material suppliers can produce levels of polymer degradation. Get around it with better control over either the temperature of the melt or the barrel residence time.

Read MoreWhat is the Allowable Moisture Content in Nylons? It Depends (Part 1)

A lot of the nylon that is processed is filled or reinforced, but the data sheets generally don’t account for this, making drying recommendations confusing. Here’s what you need to know.

Read MoreTracing the History of Polymeric Materials: Part 31, The Conclusion

Let’s close this lengthy series with some personal anecdotes.

Read MoreTracing the History of Polymeric Materials -- Part 30: Polyurethane

In the world of polymers, polyurethane chemistry is probably the most versatile. This a resulted in a wide range of products made from these materials and given the industry the flexibility to respond to the progressive march of regulatory concerns.

Read MoreTracing the History of Polymeric Materials -- Part 29: Polyurethane

This material family has unparalleled versatility, not only in terms of the forms the material can take, but in the different ways in which it can be processed.

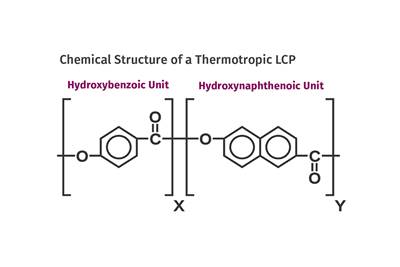

Read MoreTracing the History of Polymeric Materials, Part 28: Making LCP's Melt Processable

Liquid-crystal polymers based on a single monomer produces a polymer with a very high melting point.This presents two problems. Here’s how they were solved.

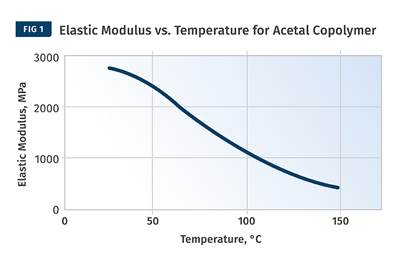

Read MoreThe Effects of Time on Polymers

Last month we briefly discussed the influence of temperature on the mechanical properties of polymers and reviewed some of the structural considerations that govern these effects.

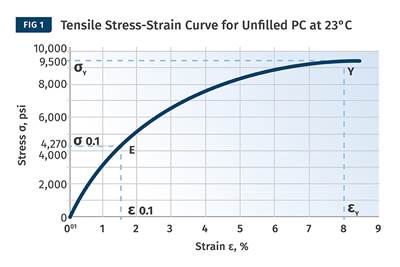

Read MoreThe Effects of Stress on Polymers

Previously we have discussed the effects of temperature and time on the long-term behavior of polymers. Now let's take a look at stress.

Read MoreTracing the History of Polymeric Materials, Part 27: Liquid-Crystal Polymers

Liquid-crystal polymers debuted in the mid-1980s, but the history of the chemistry associated with this class of materials actually starts a century earlier.

Read More