Mold Maintenance

Cold Jet Builds New Cincinnati Headquarters

Cold Jet is consolidating two Cincinnati-area facilities into one location.

Read MoreHigh-Performance Universal Lubricant

Nanoplas says MIN-LUBE high-performance grease is designed for severe environments, as well as food and pharmaceutical related spaces.

Read MoreMolders’ Block: Dealing With Foreign Materials in a Hot-Runner System

Understanding plastic flow can help you understand how foreign materials move—or don’t move—through your hot-runner system.

Read MoreCPT to Offer Mold-Handling Equipment

Cincinnati Process Technologies (CPT) has partnered with German firm RUD (Aalen) to offer that company’s full line of mold-handling equipment in the U.S. and Canada.

Read MoreTool Storage and Handling System Supplier Names Globeius as North American Distributor

U.K.-based Rack-Storage Ltd. will use Globeius to distribute its custom-built heavy and light duty tool storage products throughout the U.S., Canada and Mexico.

Read MoreMold Location System

Hasco’s Loc Check A5900/ is a magnetically mounted device that allows users to locate a mold wherever a mobile phone network is available.

Read MoreMold Documentation Tracking System Updated

MoldTrax’s MTWEB now allows visibility in multiple locations and five languages.

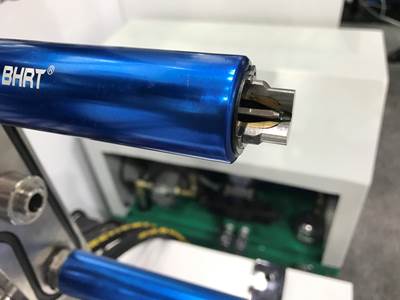

Read MoreDry Ice Blaster Upgraded

Cold Jet has updated it dry-ice cleaning system, the i3 MicroClean, with the i3 MicroClean 2 promising more power and efficiency.

Read MoreDesign Your Tools for Moldability ... and Maintenance

In the initial design phase, when considering the structure and elements of the tool, are you designing them to be maintenance friendly? Canon Virginia has used this approach and preventive maintenance to make tool replacement a thing of the past. You can, too. Here’s how.

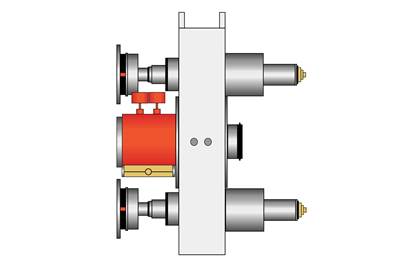

Read MoreUltrasonic System Purpose Built to Clean Injection Molds

Emerson says its ultrasonic systems can reduce mold cleaning time over manual scrubbing from hours to minutes.

Read More