PET Processing - Extrusion

How to Effectively Reduce Costs with Smart Auxiliaries Technology

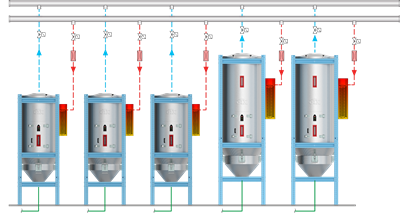

As drying, blending and conveying technologies grow more sophisticated, they offer processors great opportunities to reduce cost through better energy efficiency, smaller equipment footprints, reduced scrap and quicker changeovers. Increased throughput and better utilization of primary processing equipment and manpower are the results.

WatchGreen’s the Theme in Extrusion/Compounding

The drive toward circular economy is requiring processors to make more use of PCR. Machine builders at K—across all extrusion processes—will be highlighting innovations to help them do just that.

Read MoreDeDuster Systems Cleans Up rPET Sheet

rPlanet cut its gel count drastically—allowing it to sell more sheet at prime prices—after installing a DeDuster system.

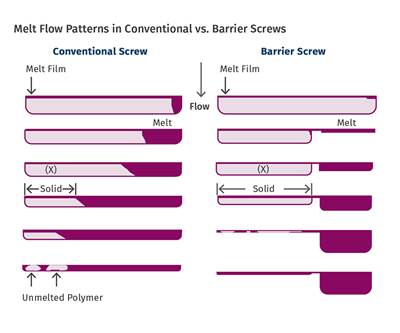

Read MoreExtrusion: Important Polymer Melting Equations for Extrusion Processors

The more you know about what happens in a screw, the more you’ll be able to work with your supplier to optimize design.

Read MoreInnovation, Customization & Sustainability: How Flex Films Focuses on U.S. Market

Global player in BOPET film has big plans for U.S. market with innovative products developed collaboratively with customers while paying heed to environmental concerns.

Read MoreKanarski to Lead Davis-Standard’s Technical Product Team

Will collaborate with suppliers and customers to evaluate market trends and capabilities, and develop technology accordingly.

Read MoreDavis-Standard Adds James Johnson as Regional Sales Manager

‘Brings industry sales, manufacturing and adhesives experience to position.’

Read MoreNDC Names Perry V.P. Sales/Marketing

Gauging specialist hires sales veteran to lead global team.

Read MoreSouth Korean Machine Builder Licenses Novel Foam Processing Technology

New technology takes aim at foaming semi-crystalline polymers such as PLA, PET and PP.

Read MoreWhat You Need to Know to Get into Coextrusion

Key considerations range from determining the right extruder sizes to tooling, matching material viscosities, and lots more. Take a look.

Read More