Testing

Height Gauge With Added Features and Accuracy

NPE 2024: Mitutoyo America’s LH600F features a touchscreen interface that enables easy and intuitive operation.

Read MoreUpdated Interactive Tool for Predicting Multilayer Film Performance

NPE 2024: NOVA Chemicals presents the latest enhancements to its Bonfire Multilayer Property Predictor and new Syndigo rPE portfolio

Read MoreUpgrade to Accelerated Artificial and Natural Weathering Testing

Atlas S³T system is designed for the company’s Weather-Ometer Ci4400 and Ci5000 instruments.

Read MoreSensors Measure Moisture in PVB Films, Pellets

NPE2024: Noncontact sensors provide a continuous, reliable reading with zero drift and no maintenance.

Read MorePowerful and Versatile Infrared Spectrometer

Thermo Fisher Scientific’s Nicolet Apex FTIR is well suited for a wide range of applications including materials analysis.

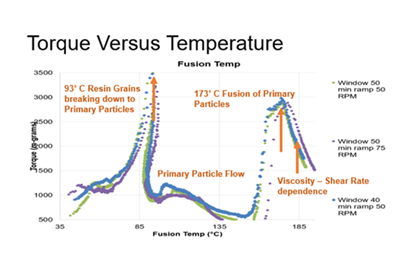

Read MoreTry This Alternate Method for Heating Your Torque Rheometer

Rheometers are generally not on all the time. And most users have found that the first test run in the instrument after heating up is not very reliable and is usually discarded. Try this method instead.

Read MoreInline Measurement Adds Module for Inspection of High-Gloss Vehicle Trims

Pixargus’ Shiny Detection module casts a pattern of structured light onto the high-gloss surfaces of the profiles to be inspected.

Read MoreMeasuring Technology Specialist Pixargus Acquired by CiTex Group

A global player in optical inline quality control, Pixargus is intensifying presence in U.S. & Asia under CiTex umbrella.

Read MoreBrabender GmbH Bought By Austrian Measurement Company

Leading metrology company Anton Paar buys 100-year old firm, known in the U.S. as C.W. Brabender.

Read MoreRobust Rotational Viscometer

Versatile viscometer line said to offer robust measurement, repeatability and reporting.

Read More