Thermoforming

On-Site: Green Business Is Good Business for Fabri-Kal

Learning to deal with the particular characteristics of PLA biopolymer has opened up a promising business in “green” plastics for thermoformer Fabri-Kal.

Read MoreNPE 2009 Wrap-Up: New Machinery for Thermoforming

NPE had its share of innovations in thermoforming, notably a new machine that opens the small-bottle market to thermoformers. New trim stations offer more in the way of output and versatility. And more machines are now outfitted with off-the-shelf controls to facilitate servicing. A line of formers from Australia also arrived in the U.S. (Note: additional NPE thermoforming news appeared in May and June—see Learn More box.)

Read MoreNPE News in Thermoforming

For thermoforming of both heavy-gauge sheet and thin-gauge packaging, the show will present new machines with unusual flexibility, able to form a wide variety of products and materials.

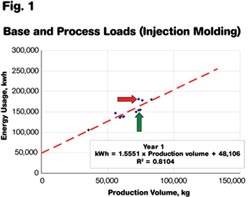

Read MoreInternal Benchmarking: Setting Targets

Last month, we discussed how to graph your plant’s “process energy fingerprint.” Now we’ll show you how to make use of that information.

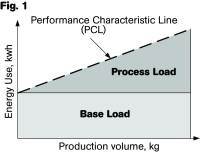

Read MoreWhat’s Your Process Energy Fingerprint?

As we discussed in last month’s column, your plant’s “energy fingerprint” is composed of the base load and the process load.

Read MoreKnow Your Plant’s ‘Energy Fingerprint’

It is commonly thought that energy use in plastics processing is fixed and uncontrollable.

Read MoreIntroduction to Energy Management For Plastics Processors

Energy efficiency is one of the “hot” topics of the 21st century and plastics processors around the world are trying to come to terms with it.

Read MoreRobots Manage Logistics For Entire Packaging Plant

Inventory management may be too important to be left to people.

Read MorePlastic Pallets Gain Ground In an Eco-Conscious World

Low-cost wood is still king, but plastics’ reusability is a growing attraction among manufacturers looking for sustainable material-handling options. The one major hurdle is today’s high resin prices.

Read MoreInvesting in Planet-Friendly Packaging

Clear Lam Packaging Inc. is a mid-sized, family-owned packaging company with an enviable growth rate of over 20%/yr, unusual at a time when many mid-sized packaging companies are being bought out and disappearing. The secret, Clear Lam believes, has been its aggressive investment in R&D.

Read More

.png;maxWidth=300;quality=90)