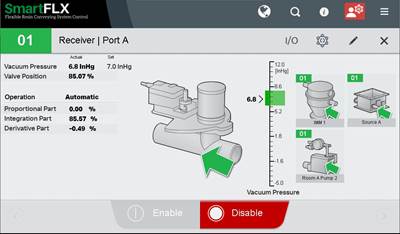

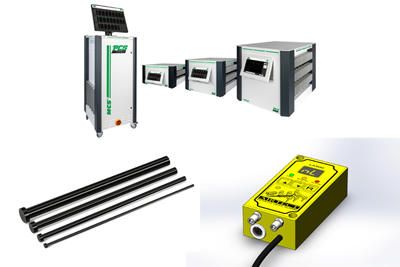

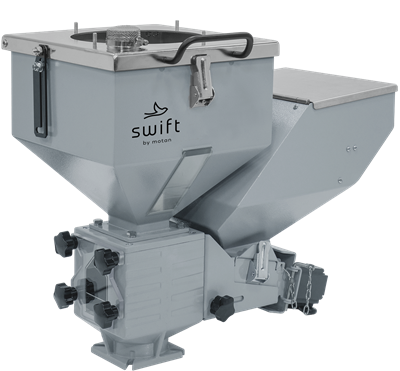

Connectivity for Material Handling Offers Greater Visibility

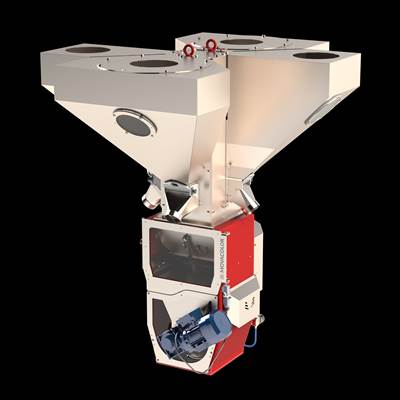

NPE2024: Motan solutions integrate data connectivity.

Read MoreYour Business

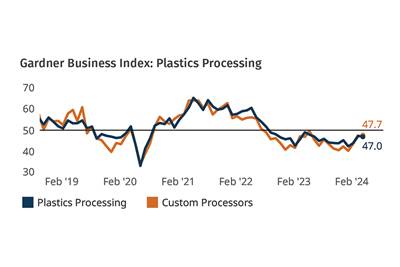

Prices for PE, PS, PVC, PET Trending Flat; PP to Drop

Despite price increase nominations going into second quarter, it appeared there was potential for generally flat pricing with the exception of a major downward correction for PP.

Read MorePrices Up for All Volume Resins

First quarter was ending up with upward pricing, primarily due to higher feedstock costs and not supply/demand fundamentals.

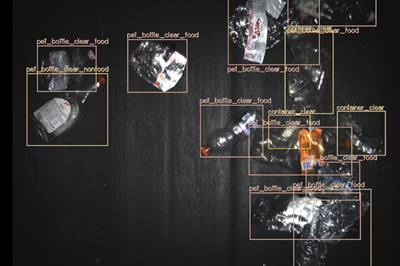

Read MoreAustrian Recycler's Mission to Recycle PET Takes It Beyond Bottles

Mission PET supplements bottle-to-bottle capability with alternative applications for recycled PET.

Read MoreProcessing Plant Tour

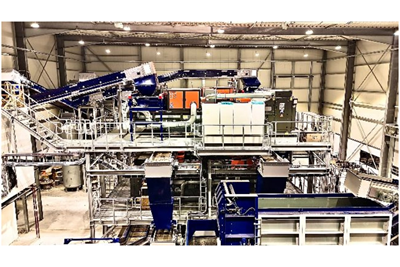

Engineering Resins Compounder Expands to Take on More Scrap

Polymer Resources responds to sustainability push by upgrading plant with grinding and shredding equipment to take on both postindustrial and postconsumer reclaim.

Read MoreBack in the Family Business

In its 45th year, Precision Molded Plastics has carved out a technology and market niche, growing not just when opportunities arise but when they make sense, after its leader changed careers to keep the family business from changing hands.

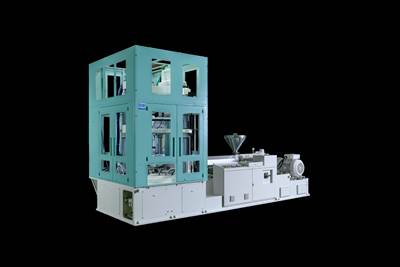

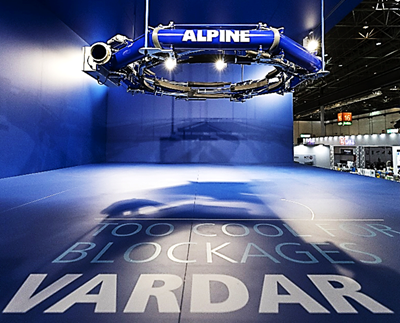

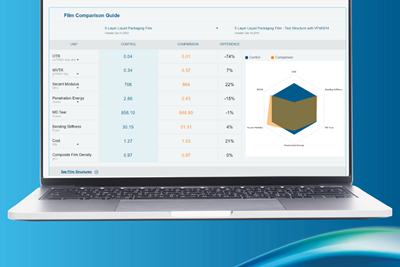

Read MoreBreaking the Barrier: An Emerging Force in 9-Layer Film Packaging

Hamilton Plastics taps into its 30-plus years of know-how in high-barrier films by bringing novel, custom-engineered, nine-layer structures resulting from the investment in two new lines.

Read MoreTechnology in Depth

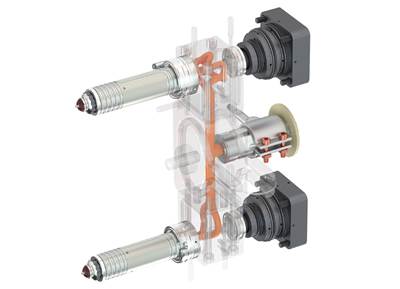

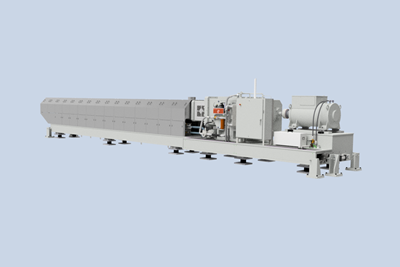

Finding Efficiencies in How Components Work Together

Auxiliary systems are vital to the proper functioning of a plastic processing line, and they can be a source of major cost and efficiency improvements.

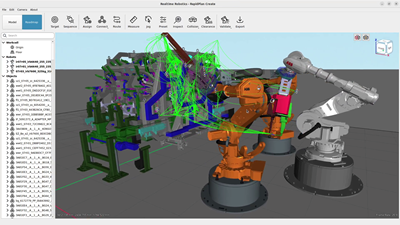

Read MoreDigital Twin Creates New, Virtual Paths for Robots with Real-World Cycle-Time Impacts

Realtime Robotics seeks to get more robots involved in manufacturing by addressing the biggest current barrier: programming costs.

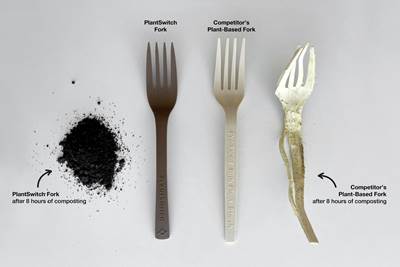

Read MorePHA Compound Molded into “World’s First” Biodegradable Bottle Closures

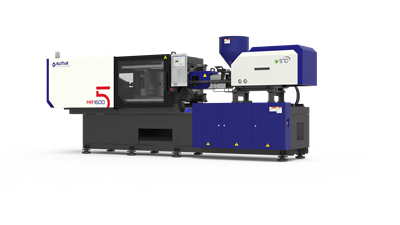

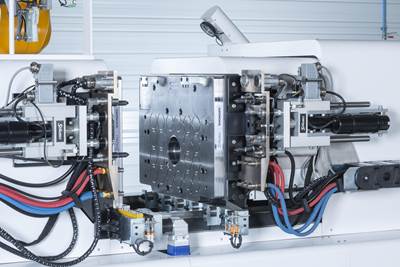

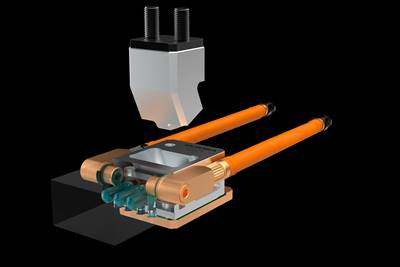

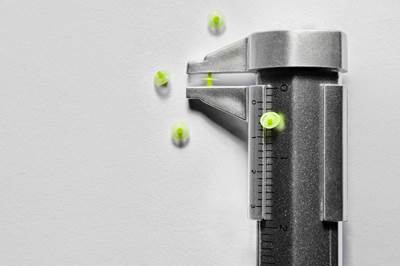

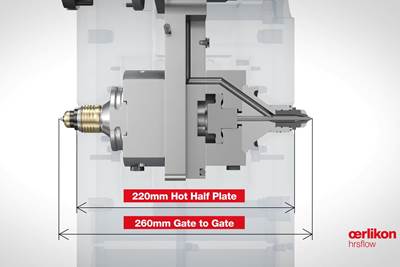

Beyond Plastic and partners have created a certified biodegradable PHA compound that can be injection molded into 38-mm closures in a sub 6-second cycle from a multicavity hot runner tool.

Read More

KNOWLEDGE CENTERS

Gain in-depth knowledge in processes, products and technology from industry experts

Trending

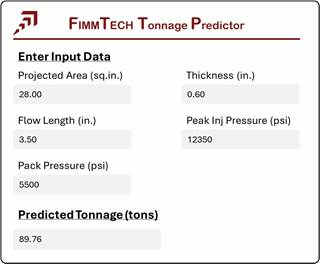

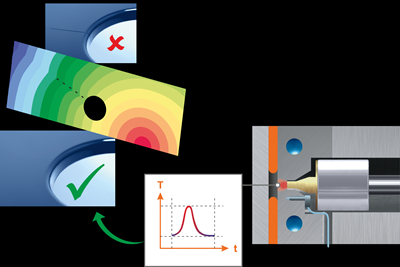

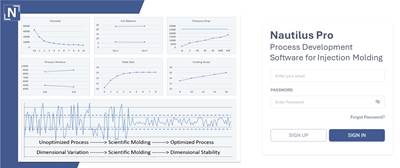

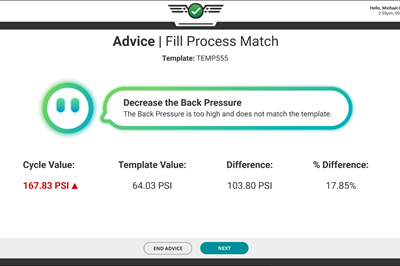

- Understanding the Effect of Pressure Losses on Injection Molded Parts

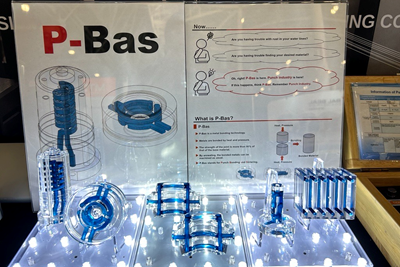

- Processing Megatrends Drive New Product Developments at NPE2024

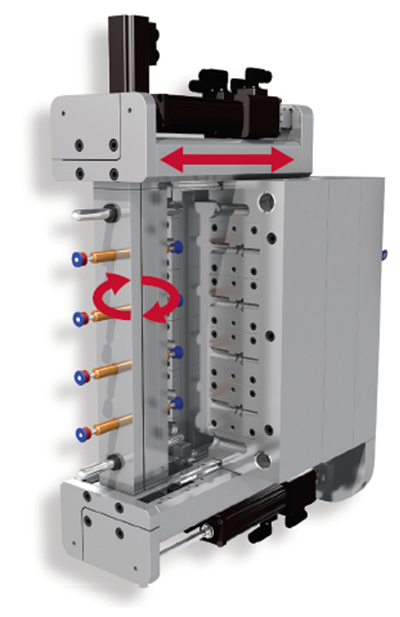

- How To Design Three-Plate Molds – Part 4

- Four Industry 4.0 Tech Adoption Insights from Indiana Plastics Manufacturers

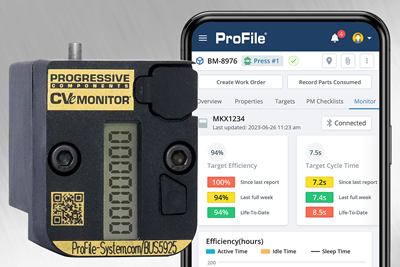

- Real-Time Production Monitoring as Automation

- New Blown-Film Cooling Technologies Set to Debut at NPE2024

- Unraveling the Science and Myth Associated With Moisture Analysis — Part 2

- Prices of All Five Commodity Plastics On the Way Up

- Consistent Shots for Consistent Shots

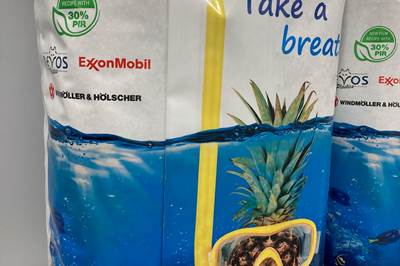

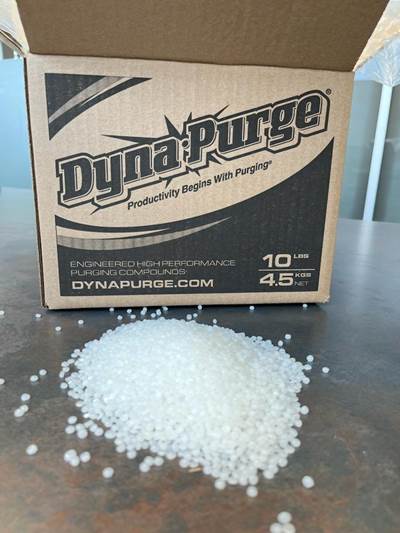

- Use Purging Compounds to Mitigate Processing Challenges of PCR and PIR

Solutions

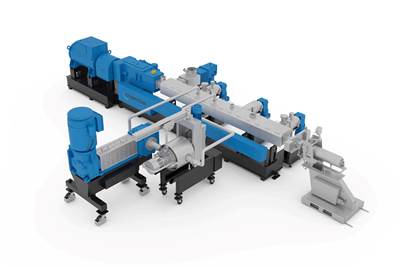

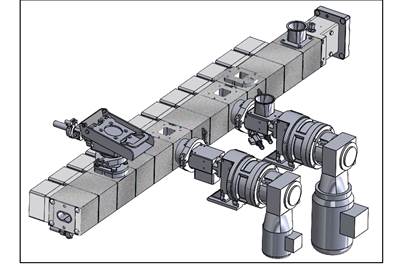

How to Configure Your Twin-Screw Extruder for Mixing: Part 5

Understand the differences between distributive and dispersive mixing, and how you can promote one or the other in your screw design.

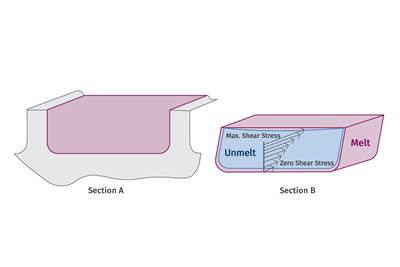

Read MoreThe Role Barrel Temperatures Play in Melting

You need to understand the basics of how plastic melts in an extruder to properly set your process and troubleshoot any issues. Hint: it’s not about the barrel temperature settings.

Read MoreFundamentals of Polyethylene – Part 6: PE Performance

Don’t assume you know everything there is to know about PE because it’s been around so long. Here is yet another example of how the performance of PE is influenced by molecular weight and density.

Read More

Latest Issue

Essential Reading

Best of Fattori, Tooling Know How

In this collection of articles Jim Fattori offers his insights on a variety of molding-related topics that are bound to make your days on the production floor go a little bit better.

Read MoreScrew Design Tips to Boost Productivity

In this collection of articles, two of the industry’s foremost authorities on screw design — Jim Frankland and Mark Spalding — offer their sage advice on screw design...what works, what doesn’t, and what to look for when things start going wrong.

Read MoreFundamentals of Polyethylene – Part 5: Metallocenes

How the development of new catalysts—notably metallocenes—paved the way for the development of material grades never before possible.

Read MorePolyethylene Fundamentals – Part 4: Failed HDPE Case Study

Injection molders of small fuel tanks learned the hard way that a very small difference in density — 0.6% — could make a large difference in PE stress-crack resistance.

Read MoreWhat You Need to Know About the Design and Operation of Maddock Mixers

Designed properly, all entering solid polymer fragments and certain types of PE gels entering the Maddock mixer can be trapped and dispersed into the matrix resin. But many are not properly designed. Here’s what to look out for.

Read MoreFundamentals of Polyethylene – Part 3: Field Failures

Polyethylene parts can fail when an inappropriate density is selected. Let’s look at some examples and examine what happened and why.

Read MoreLatest News and Products

Carbios and Partners Celebrate Groundbreaking for PET Biorecycling Plant

New plant will use enzymatic process to depolymerize PET.

Read MoreManual Leak Tester and Vision Option

NPE2024: New from ALPS Inspection are the affordable BenchPlus manual leak tester and a vision option to add defect detection to leak testers.

Read MorePerformance Phosphite Antioxidant and Extended Service Life UVA for Polyolefins

NPE 2024: Songwon’s Songnox 9228 phosphite enhances resistance to oxidative corrosion while Songsorb 1164 UVA outperforms benzotriazoles.

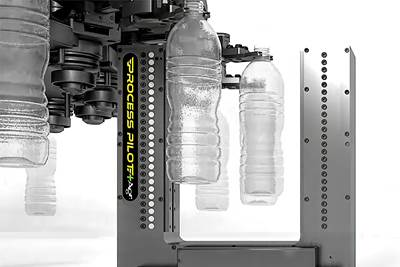

Read MoreCobot Palletizing System for Bottles

NPE2024: Proco Machinery’s new collaborative robot system palletizes bottles with trays and tier sheets up to 104 in. high.

Read MorePolyfuze Graphics Corp. Partners With RFID Specialists

To help customers navigate the complexities of RFID technology, Polyfuze has partnered with such companies as HID Global.

Read MoreBrightmark Intends to Build Recycling Circularity Center in Upson County, Georgia

The company announced plans for an investment totaling $950 million.

Read MoreMold Solutions Target Safety, Storage and Productivity

NPE2024: Globeius and its suppliers showcase solutions focused on decreasing downtime, reducing energy consumption, increasing safety and more in an injection mold shop.

Read MoreFormlabs Form 4 Prints at Double to Quintuple Speed

Formlabs announces SLA printer with much greater speeds than previous generation.

Read More