High-Torque Twin & Novel Feeding System Debut for Compounding

ENTEK takes the wraps off three innovations aimed at increasing productivity.

ENTEK Manufacturing has introduced a series of new products aimed at compounders, including the first in what will eventually be a series of high-torque, co-rotating twin-screw extruders, along with new vent-flow sensing and vacuum-feed technology. Originally slated to debut in May at the cancelled NPE2021 show, they were unveiled by ENTEK at a virtual press conference held in June from its Lebanon, Ore., headquarters.

The newest machine is a 72-mm co-rotating twin-screw that is the first in ENTEK’S HT (high-torque) series. According to the company, the new extruder reportedly delivers the industry’s highest free volume of 1.61 Do/Di at 18 Nm/cm3 torque density, and—depending on the formulation and other factors—can operate at rates up to 10,000 lb/hr.

New HT72 twin-screw compounding extruder from ENTEK is the first machine in what’s expected to be a series of high-torque models. This machine reportedly delivers the highest free volume at 18 torque density in the industry.

The target markets, not surprisingly, are high-output commodity and masterbatch compounding, an area that ENTEK previously has not served. In these applications, compounders typically run medium-to-large batch production sizes, and high production rates are particularly critical. And they typically run on a 24/7/365 basis. The machine features an oversized motor and is also said to be well suited for other applications that are torque or power limited.

“We now have an ideal solution for those needing high throughput for continuous production of large batches of materials,” says Linda Campbell, ENTEK’s v.p. of sales “It represents almost three years of research and development, and the end result is a completely new machine that provides industry-best performance.”

“Processors can achieve much higher throughput, as much as twice the output rate without VFT.”

Specific features of the HT72 include:

• “Mistake-proof” screw elements and shafts;

• Overall Equipment Effectiveness (OEE) dashboard for quick performance stats;

• Low-decibel, water-cooled motor;

• Real-time vibration monitoring;

• Real-time oil-quality monitoring;

• Easy-access offboard cooling system;

• Full stainless-steel shroud for easy cleaning;

• Insulation blankets to retain heat;

• Point-of-use tools;

• Quarter-turn, standardized retained fasteners; and

• Hinged guards for quick access

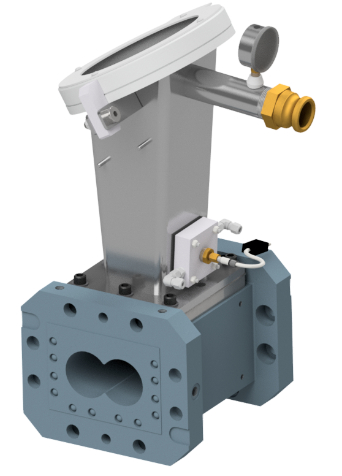

ENTEK also took the wraps off a patent-pending Vent Flow Sensor that is intended to nip vent-flow problems in the bud before they wreak havoc on the process or potentially cause fires. Vent flow happens when material escapes through a vent opening, preventing air/gases from escaping the extruder. The optional sensor will alarm if it detects a potential problem with vent flow. If so furnished, the PLC can automatically take corrective action—such as shutting down the feeders or the entire line. Or, operators will have the time to correct any processing issues before they become problematic. The device is furnished with a cooled tower, which makes vent-flow cleaning easier.

New Vent Flow Sensor detects when vent flow is beginning to occur so that steps can be taken to prevent fires and other hazards.

New Vacuum Feeding System

ENTEK also announced a patented processing technology designed to improve twin-screw extruder throughput rates. The new Vacuum Feed Technology (VFT) is recommended for compounders whose process is volumetrically limited by powdered materials and for those using atmospheric vents that discharge messy powders.

“VFT is the solution if a compounder is challenged by a process that is volumetrically limited when processing low-bulk-density powdered materials,” notes Dean Elliott, ENTEK’s technical processing manager. “Processors can achieve much higher throughput—as much as twice the output rate without VFT.”

With the new feeding technology, a vacuum pulls out air that would otherwise be entrapped in the material in order to facilitate feeding. Since VFT does not require vents open to atmosphere, this technology solves the problem of powdered materials potentially spewing out the atmospheric vent of the extruder. “This not only prevents a messy situation but creates a safer workplace environment,” says Elliott.

ENTEK has tested the VFT on a 43-mm twin in its Oregon lab. Running PP loaded with 40% and 60% talc, the machine generated 1.8 times more output than with conventional atmospheric venting for air relief.

Offered by license and retrofittable, ENTEK’s VFT includes pilot-plant trials at ENTEK to configure the extruder for the customers’ formulation and to demonstrate the throughput improvement compared with standard atmospheric extruder venting. Complete documentation of the screw and barrel configuration is provided, along with on-site process startup support at the customer’s location.

Related Content

Film Processor Automates Complex Resin Management, Blending & Distribution System

Polipak of Poland moves to BlendSave system to support sustainability and Industry 4.0 objectives.

Read MorePiovanGroup Rebrands, with Mostly Minor Name Changes

For the most part, subsidiary company names will remain, with slight modifications meant to enhance the Group’s identity.

Read MoreFinding Efficiencies in How Components Work Together

Auxiliary systems are vital to the proper functioning of a plastic processing line, and they can be a source of major cost and efficiency improvements.

Read MoreFive Quick Steps Toward Better Blending

Rising costs of resins and additives, along with higher demands for quality and use of regrind, place a premium on proficient blending. Here are some steps to get you there.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreRecycling Partners Collaborate to Eliminate Production Scrap Waste at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair will seek to recover and recycle 100% of the parts produced at the show.

Read More