Eastman Collaborates with Rotuba to Make Face Shields for Coronavirus Pandemic Frontliners

Eastman’s high-molecular-weight cellulose acetate CA-398-30 boasts excellent physical and optical properties for molded items such as the Rotuba face shields in the fight against COVID-19.

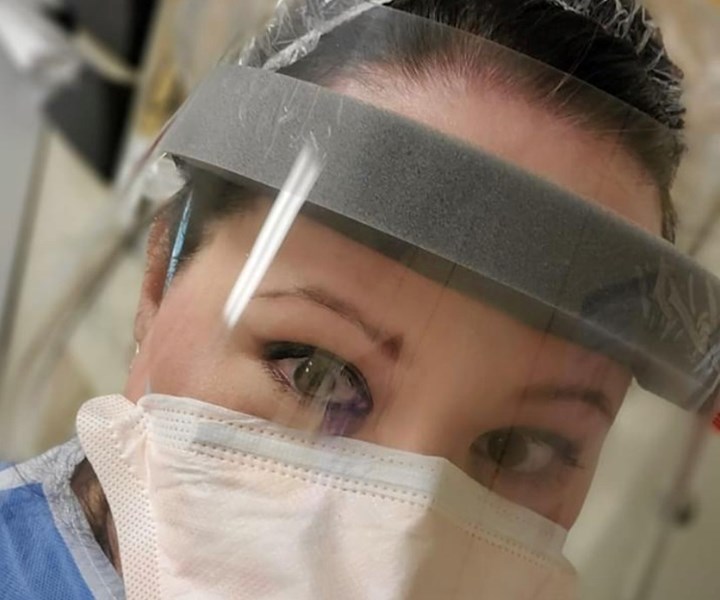

A collaboration to produce face shields for medical personnel on the frontlines of the coronavirus pandemic is underway between Eastman Chemical, Kingsport, Tenn., and custom compounder Rotuba, Linden, N.J. Rotuba is said to be the largest independent global custom compounder of cellulosics, a wood-based polymer used in faceshields, eyeglass frames and tool handles. The company also owns and operates Pen Company of America (formerly known as Rotary Pen), said to be the only pen company still manufacturing pens in the U.S., which includes the RevMark brand of writing utensils.

Rotuba was quickly able to transition its business operations from manufacturing pens to manufacturing face shields by utilizing an existing material in a new application. The 75,000 to 100,000 splash guards will be sold across the United States and supplied to first responders at the cost to produce them.

The material used by Rotuba is Eastman’s high-viscosity, high molecular weight cellulose acetate CA-398-30 supplied as fine, dry, free-flowing powder. The powder is free from coarse particles and excessive fines. Its relatively uniform particle size permits good plasticizer distribution during blending. When CA-398-30 is dissolved in appropriate solvents a clear, colorless solution is produced. Cellulose acetate CA-398-30 offers good physical properties for molded and extruded articles. It may be compounded into plastic using extrusion equipment or heated rolls.

Moreover, CA-398-30 is based on cellulose, one of the most abundant natural renewable resources, from trees harvested from sustainably managed forests.The calculated approximate bio-content value of 55% for Eastman CA-398-30 was determined by using six bio-based carbon atoms per anhyroglucose unit divided by the total number of carbons per anhyroglucose unit. Although the value reported is not specifically measured for bio-carbon, it can be estimated based on typical partition data.

Said Adam Bell, president, Rotuba and Pen Company of America, “Eastman and Rotuba have had a long relationship spanning over five decades of developing items consumers buy every day.When we needed a reliable supply of cellulose acetate for these face shields, we turned to Eastman…. Keeping our workforce utilized by producing the face shields instead of pens has been a great help. Thanks to the support and continued partnership Eastman has provided, we have been able to keep 35 workers employed who might have otherwise been furloughed or laid off as a result of the crisis."

Said Reinier de Graaf, Eastman’s marketing director, specialty plastics — diversified, "Eastman is proud to work with Rotuba to provide much-needed supplies to those who need them most. We will continue to work with companies across the value chain to quickly adapt their operations to meet unmet needs during this crisis."

.

Related Content

-

Melt Flow Rate Testing–Part 1

Though often criticized, MFR is a very good gauge of the relative average molecular weight of the polymer. Since molecular weight (MW) is the driving force behind performance in polymers, it turns out to be a very useful number.

-

How to Optimize Your Molds and Hot Runners for Processing Bioresins

Demand for bioresins is growing in molded goods, particularly as a sustainability play to replace fossil-fuel based materials, but these materials are not a drop-in replacement for traditional materials. Molds and hot runners need to be optimized for these materials.

-

50 Years of Headlines … Almost

I was lucky to get an early look at many of the past half-century’s exciting developments in plastics. Here’s a selection.