Profile Die Design Software Simulates Cooling, Shrinkage

Enables use up of to 20 calibrators in the cooling system.

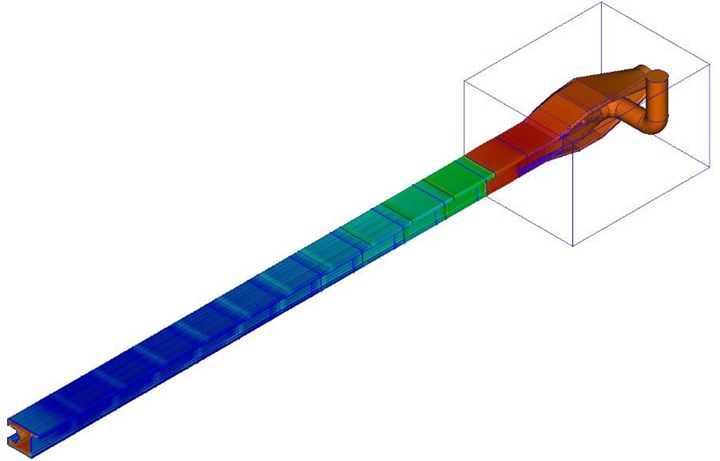

The new version of polyXtrue profile-die design software from Plastics Flow is said to accurately simulate extrudate cooling and corresponding extrudate shrinkage in the complete cooling system. It included the following features:

- Twenty calibrators and sizers in the cooling system.

- Two different temperature zones between calibrators. One of the two temperature zones can be a wiper between a water tank and the next calibrator.

- Ten different temperature zones between the die exit and the first calibrator

- Ten different temperature zones are allowed after the last calibrator.

With the software, calibrator profiles can be different from the die exit profile. By gradually changing the shape of the profile in subsequent calibrators, the shape of the extrudate profile can be significantly modified after it leaves the die, allowing extrusion of complex profiles from relatively simple die geometries.

Die geometry files can be imported from SolidWorks, Inventor and Creo software. The new version allows users to import die geometries in native Creo file format. The die geometries in SolidWorks and Inventor file formats can also be imported as before.

Related Content

-

Cooling the Feed Throat and Screw: How Much Water Do You Need?

It’s one of the biggest quandaries in extrusion, as there is little or nothing published to give operators some guidance. So let’s try to shed some light on this trial-and-error process.

-

Formulating LLDPE/LDPE Blends For Abuse–Resistant Blown Film

A new study shows how the type and amount of LDPE in blends with LLDPE affect the processing and strength/toughness properties of blown film. Data are shown for both LDPE-rich and LLDPE-rich blends.

-

The Importance of Viscosity in Melting

The calculations required to determine the right melt temperature for each polymer are complicated. Knowing the power-law coefficient and the consistency index of the polymer you run might prove useful.

(2).jpg;maxWidth=300;quality=90)