best practices

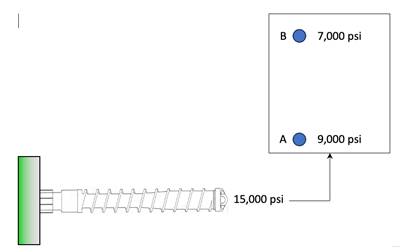

Understanding the Effect of Pressure Losses on Injection Molded Parts

The compressibility of plastics as a class of materials means the pressure punched into the machine control and the pressure the melt experiences at the end of fill within the mold will be very different. What does this difference mean for process consistency and part quality?

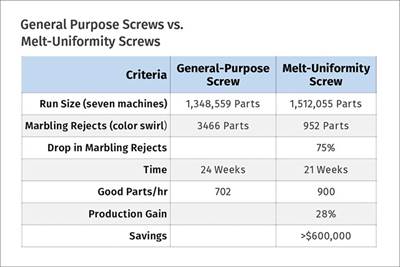

Read MoreImprove Production Rates Via Screw Design — Barrier vs. General Purpose vs. Melt Uniformity

I’m looking for a few good molders to help trial a new screw design, and share data and results for a future article to prove the benefits of a melt uniformity screw.

Read MoreAPR Expands Design Guide for Plastics Recyclability With Polypropylene Categories

Six new packaging categories will be eligible for third-party validation of compatibility with North American recycling programs.

Read MoreAvoiding Common Cosmetic Defects in Molded Parts

Identify familiar flaws and then work to eliminate them with these mold and part design tips, and process considerations.

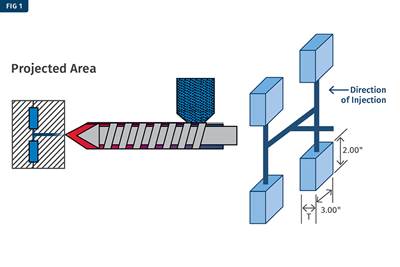

Read MoreIs There a More Accurate Means to Calculate Tonnage?

Molders have long used the projected area of the parts and runner to guesstimate how much tonnage is required to mold a part without flash, but there’s a more precise methodology.

Read MoreWhere and How to Vent Injection Molds: Part 3

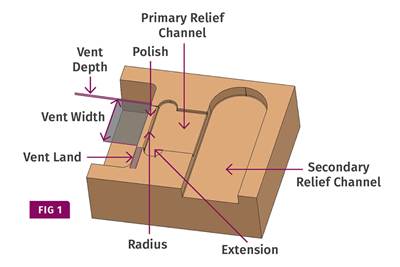

Questioning several “rules of thumb” about venting injection molds.

Read MoreBack to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

Read MoreUltrasonic Welding: Tips, Techniques, and Troubleshooting

In this collection of content, we provide expert advice on welding from some of the leading authorities in the field, with tips on such matters as controls, as well as insights on how to solve common problems in welding.

Read MoreASTM Standard To Support Sustainable Plastics

Plastics committee is developing a standard to support a circular economy for plastics.

Read MoreBack to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

Read More