best practices

A Simpler Way to Calculate Shot Size vs. Barrel Capacity

Let’s take another look at this seemingly dull but oh-so-crucial topic.

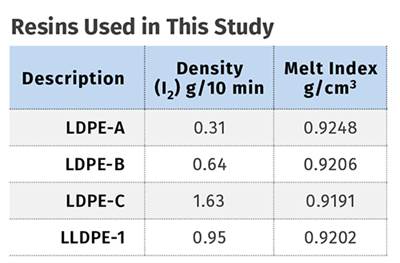

Read MoreFormulating LLDPE/LDPE Blends For Abuse–Resistant Blown Film

A new study shows how the type and amount of LDPE in blends with LLDPE affect the processing and strength/toughness properties of blown film. Data are shown for both LDPE-rich and LLDPE-rich blends.

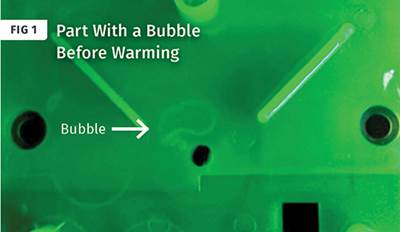

Read MoreHow to Get Rid of Bubbles in Injection Molding

First find out if they are the result of trapped gas or a vacuum void. Then follow these steps to get rid of them.

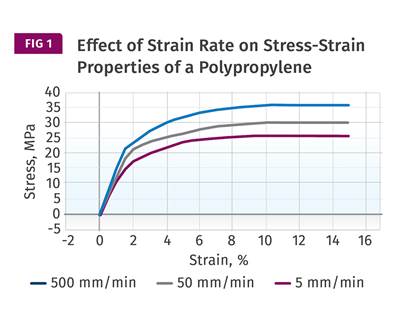

Read MoreUnderstanding Strain-Rate Sensitivity In Polymers

Material behavior is fundamentally determined by the equivalence of time and temperature. But that principle tends to be lost on processors and designers. Here’s some guidance.

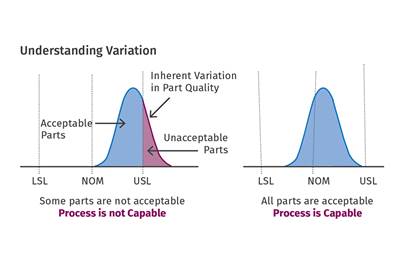

Read MoreCreating a Capable Process Using Process Capability

Know your Cp from your Cpk and how parts can meet dimensional specifications but still not be “capable.”

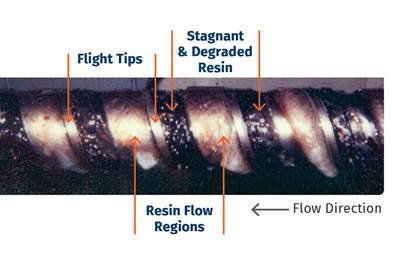

Read MoreHow Screw Design Can Mitigate Gels in PE Films

Gels are a constant issue in production of PE films using single-screw extruders. Gels can create quality issues via optical flaws, and they can cause the film to break on blown or cast film lines. There are numerous origins for gels, and the mitigation method depends on knowing the gel type.

Read MoreHow to Set Up Mold Protect on Your Injection Machine

Set the start position for mold protect where anything in the mold could be subject to damage.

Read MoreFollow These Tips to Maximize Purging Efficiency

Commercial purging compounds offer dedicated solutions to your equipment cleaning needs, but some can be more effective in cleaning the ‘dead areas’ in certain screws and tooling. Follow these tips to choose the right one for your application, and make sure to follow the right protocol when shutting down for long periods.

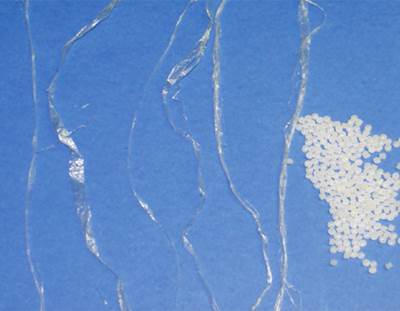

Read MoreSix Tips to Prevent Those Annoying Streamers

Streamers are a vexing problem that can foul up production. If you have time and budget constraints, there “at-home” solutions you can try. But once you’ve exhausted those routes, you might have to throw a little money at the problem. Here’s a process engineer’s view of things.

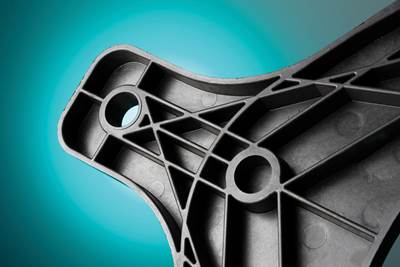

Read MoreThe Long and Short of It (Part 2)—Tips for Molding Short-Fiber Reinforced Polymers

Following on a similar guide for long-fiber reinforced compounds, here are practical tips on designing and injection molding parts utilizing short-fiber reinforcements.

Read More