Compounding

Hillenbrand Buys Schenck

Materials handling and feeding company to join forces with Coperion/Coperion K-Tron.

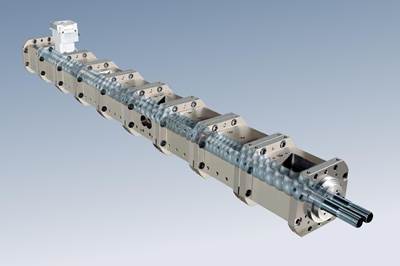

Read MoreHow to Configure Your Twin-Screw Extruder -- Part 2

Follow these tips to configure your twin-screw elements to promote feeding and solids conveying.

Read MoreBay Plastics Offering Free Pelletizing Trials

Lab trials and offers two types of extruders, two models of pelletizers, and manual strand or auto strand pelletizing capabilities.

Read MoreTwin-Screw Feeder Ideal for Hard-to-Handle Materials

Twin-screw gravimetric feeder features a horizontal agitator so that the two screws are always filled with material.

Read MoreInline Ultra High Shear Mixer

Designed to deliver exceptional dispersion, emulsification, and homogenization at high throughput.

Read MoreENTEK Expanding in Machinery, Battery-Film Processing

Showcases new plant to support machinery business, announces plans to build bigger compounding extruder and lays out strategy to build two new battery-separator plants.

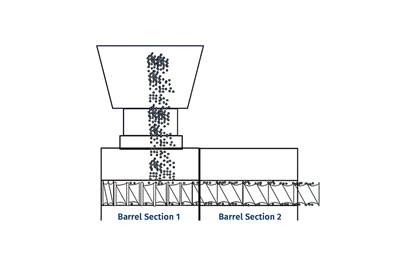

Read MoreHow to Configure Your Twin-Screw Barrel Layout

In twin-screw compounding, most engineers recognize the benefits of being able to configure screw elements. Here’s what you need to know about sequencing barrel sections.

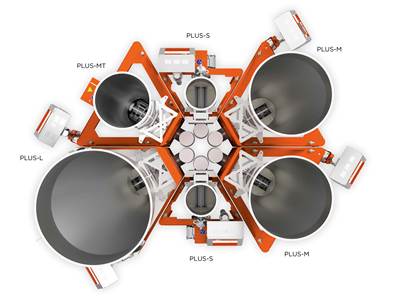

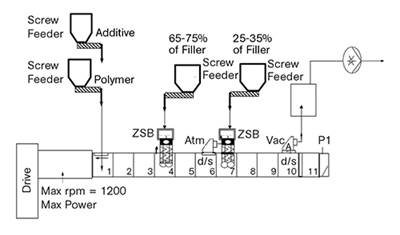

Read MoreImproving Twin-Screw Compounding of Reinforced Polyolefins

Compounders face a number of processing challenges when incorporating a high loading of low-bulk-density mineral filler into polyolefins. Here are some possible solutions.

Read MoreDual-Shaft Mixers Are Versatile, Powerful

Mixer series reportedly powerful enough to batch dispersions, suspensions, and emulsions with viscosities up to several hundred thousand centipoise.

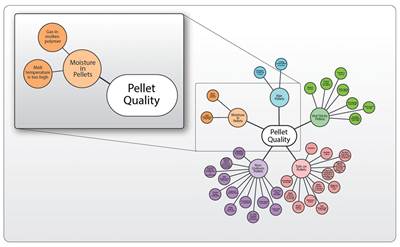

Read MoreThe Path to Pellet Perfection

In underwater pelletizing, numerous variables in the equipment, process and material affect pellet shape, consistency and quality factors such as fines. Defining the “perfect” pellet depends on the conditions of end use, and achieving that ideal requires understanding of the causes of imperfections.

Read More