Global Report Outlines How to Rid Oceans of Plastic Waste

A path that could reduce ocean plastic waste by nearly half by 2025 and reverse it in another decade outlined by new study.

The release of a new global report that both identifies the origins of the global ocean plastic debris and how it leaks into the oceans and also outlines reduction solutions and their relevant economics, as well as how to trigger implementation of these solutions from the near-to-the-long-term, is being announced today by the DC-based Ocean Conservancy’s Trash Free Seas Alliance.

Annually, 8-million/m.t. of plastics leak into the oceans and the amount continues to grow. Lacking a concerted global action, this could translate to 1-ton of plastic for every 3-tons of fish by 2025, leading to massive environmental, economic, and health issues.

“Stemming the Tide: Land-based Strategies for a Plastic-Free Ocean”, is the Trash Free Seas Alliance’s signature initiative and Ocean Conservancy commissioned the McKinsey Center for Business & Environment to lead this comprehensive study. It was supported by Alliance members, the Dow Chemical Co., the American Chemistry Council, the Coca-Cola Co., World Wildlife Fund, and the Recycling and Economic Development Initiative of South Africa. It was also advised by technical pros in waste management, plastics and recycling as well as various government and multilateral organizations.

The study determined that although all countries with coastal access contribute to the ocean plastics problem, over half of the material leaked comes from five rapidly developing countries where production and consumption of plastics is outpacing local waste management capacity, in order of magnitude—China, Indonesia, Philippines, Vietnam, and Thailand.

This first-of-its-kind report identifies ways this global crisis can be diverted through a set of strategies rooted in stopping the leakage in the first place. It projects, that the implementation of a plan that starts at the local level can result in a 65% reduction of plastic pollution in these five countries, which would translate to a 45% reduction of plastics flowing in the ocean globally by 2025. Noting that there is no “one size fits all” solution, the study says that achieving this global reduction requires this mix:

• 26%: Close “leakage” points within the collection system by optimizing transport systems to eliminate illegal dumping, and closing or improving dump sites located near water ways.

• 23%: Increase waste collection rates by offering expanded service. Plastic waste is over twice as likely to end up in waterways and the ocean if uncollected.

• 16%: Keep leakage points closed by increasing the value of waste. Manually sort waste in rural areas to extract high-value plastic waste for recycling and convert the low-value waste into fuel for use in the cement industry. Deploy a mix of waste-to-fuel or waste-to-electricity technologies in cities.

In addition, the Alliance’s study stresses the need for working with industry to introduce new materials, recovery, and recycling approaches that will allow uncontrolled plastic waste to peak globally by 2030. Also, the strategies offered by the study are not plastic specific—they target the whole waste stream. If implemented today, the total program would entail a cost of $5-billion/yr. The six priority areas of action for such a global program are:

• Ensure political leadership and commitment. Obtain real and meaningful commitments from national governments, governors and mayors to set and achieve ambition waste management targets.

• Secure on-the-ground wins. Provide local “proofs of concept” for integrated waste management approaches in a number of carefully selected “beta” cities.

• Get critical mass. Use lessons learned in beta cities to enable stakeholders to build a “best practice” transfer mechanism that can accelerate the transfer of global expertise to high priority cities.

• Pave the way for funding. Ensure that required project investment conditions are in place in the private, public, and multi-layer sectors. Work with industry on an innovative mechanism to strategically reduce capital costs and investment risks.

• Facilitate technology implementation. Equip state-of-the-art waste management technology provides the detailed data on waste composition, volume, and pathways; local infrastructure, wage structure; scavenger systems; feedstock supply security; energy prices, feed—in tariffs and off-take agreements to enable implementation of scale.

• Intensify the priority. Bring leadership and strategic focus on solutions to the ocean plastic challenge as part of the global policy agenda on the ocean.

Related Content

Reversing Logistics for Plastic Film Recycling

Learn how Mainetti built a circular supply chain for clear film packaging.

Read MoreFoam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

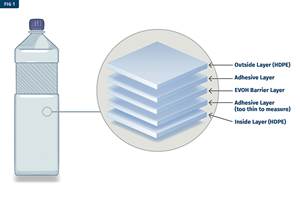

Read MoreMeasuring Multilayer Plastic Containers Made Easier With Today's Ultrasonic Gauges

Ultrasonic gauge technology has evolved to simplify measurement of very thin layers in plastic containers. Today’s gauges with high-frequency capabilities and specialized software can make multilayer container measurement quick and easy for ordinary users.

Read MorePregis Performance Flexibles: In the ‘Wow’ Business

Pregis went big and bold with investment in a brand-new, state-of-the-art plant and spent big on expanding an existing facility. High-tech lines, well-known leadership and a commitment to sustainability are bringing the “wow” factor to blown film.

Read MoreRead Next

Recycling Partners Collaborate to Eliminate Production Scrap Waste at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair will seek to recover and recycle 100% of the parts produced at the show.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More