Plastics Processing Index Remains Virtually Unchanged

Future business indicators rose again this month, but other inputs changed only slightly.

Read MoreYour Business

Prices of PP, PET Drop; PE, PS and PVC to Follow

Going into fourth quarter, prices of the five commodity resins were heading downward, barring supply interruptions.

Read MoreFighting Dust and Noise in Regrind Operations

Mayhew Basque Plastics implemented lower speed granulators to deal with challenging materials.

Read MoreAnnual Benchmarking Survey of Injection Molders Released

Plastics Technology Top Shops Benchmarking Survey provided both unanimous responses and divided results, but pervasive throughout is the sense of an industry still grappling with the aftermath of 2020’s global pandemic.

Read MoreProcessing Plant Tour

Making Gains in the Drain Game

AWD blends extrusion and thermoforming technologies with plenty of home-brewed equipment and processes to keep water away from where it isn’t supposed to be.

Read MoreInjection Molder Amplifies Automation for Optimized Production

AIM Processing has parlayed small part molding expertise and aggressive automation, even for short run production, into a highly successful custom molding business.

Read MoreSirmax Adapts Integrated Recycling Approach to US Supply Conditions

Integrating compounding and recycling to leverage untapped postindustrial recycling feedstocks.

Read MoreTechnology in Depth

Precision Processing Requires Precision Equipment

Moretto offers plastics processors and micromolders for a broad suite of auxiliary solutions targeted specifically for precision processing.

Read MoreMaterials Suppliers Team on PFAS-Free Solutions

Baerlocher PFAS-fee process aid passes muster in resin manufacturer’s testing on production-sized blown film line.

Read MoreResearch Deems Bioplastics, Wood Pulp a Sustainable, Economic Alternative for Rigid Packaging

Farrel Pomini and FPInnovations produce biodegradable compound for molding, extrusion and thermoforming applications.

Read More

KNOWLEDGE CENTERS

Gain in-depth knowledge in processes, products and technology from industry experts

Trending

- The Importance of Mass Balance in Chemical Recycling

- Polymer Science for Those Who Work With Plastic — Part 1: The Repeat Unit

- How to Decrease the Extrudate Temperature in Single-Screw Extruders

- Get the Most From Fiber-Reinforced Thermoplastic Composites Parts

- Prices Flat-to-Down for All Volume Resins

- Important Factors and Approaches to Estimating Residence Time in Injection Molding

- COVID-19’s Long Shadow

- Custom Molder Pivots When States Squelch Thriving Single-Use Bottle Business

- PCE Adding Space to Help European Suppliers Enter US Market

- Apollo Funds to Acquire Barnes Group

Solutions

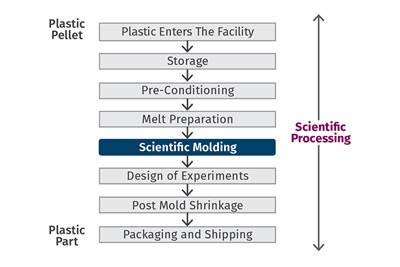

A Systematic Approach to Process Development

The path to a no-baby-sitting injection molding process is paved with data and can be found by following certain steps.

Read MoreWhat You Need to Know About Leader Pins and Bushings

There’s a lot more to these humble but essential mold components than you might suspect. Following the author’s tips could save much time, money and frustration.

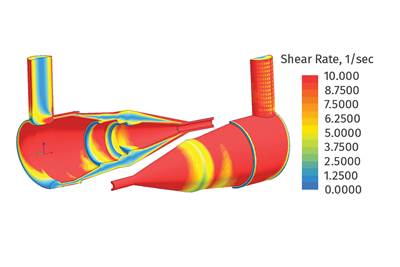

Read MorePart 2 Medical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Simulation can determine whether a die has regions of low shear rate and shear stress on the metal surface where the polymer would ultimately degrade, and can help processors design dies better suited for their projects.

Read MoreEssential Reading

Medical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Extrusion simulations can be useful in anticipating issues and running “what-if” scenarios to size extruders and design dies for extrusion projects. It should be used at early stages of any project to avoid trial and error and remaking tooling.

Read MoreWhy Are There No 'Universal' Screws for All Polymers?

There’s a simple answer: Because all plastics are not the same.

Read MoreThree Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.

Read MoreEnsuring Repeatability: The Key to Effective Injection Molding Automation

One of automation’s key promises is repeatability: the same movement to the same location, time and time again. But to achieve that, all elements involved — robot, machine, EOAT, mold — must be in and stay in alignment.

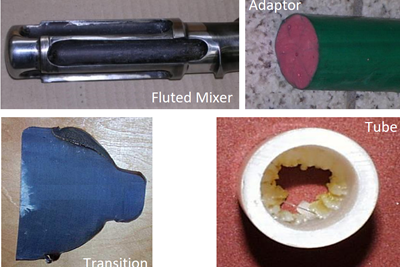

Read MoreIn Single Screw Extruders, Mixing Starts in the Melting Process

While the melting process does not provide perfect mixing, this study shows that mixing is indeed initiated during melting.

Read MoreStarting or Restarting an Injection Molding Machine — What Works Best?

Successfully starting or restarting an injection molding machine is less about ticking boxes on a rote checklist and more about individually assessing each processing scenario and its unique variables.

Read More

Latest Issue

Latest News and Products

Injection Molded Parts Competition Now Accepting Entries

Plastics Technology’s Hot Shots parts competition is accepting submissions for the 2025 contest, with winners to be announced at PTXPO 2025.

Read MoreTemperature Control Unit (TCU) Modulates Heat Output in Real Time

Delta T Systems’ Smart series water TCU features “Vari-Heat” technology for greater precision and efficiency.

Read MoreCooling Bore Creates Turbulent Flow

Hasco says its Cooling Tornado facilitates turbulent flow, boosting cooling effectiveness by up to 20%.

Read MoreDanish End-of-Arm-Tool (EOAT) Supplier Adds North American Distribution

Globeius is now distributing Roborex EOAT parts for the North American plastics industry, with online purchasing available.

Read More3Devo Filament Maker Two Enhances Extrusion Control

The machine includes an upgraded screw drive, monitoring and user interface for enhanced filament production.

Read MorePET Chemical Recycling Process Qualified and Commercialized

Process will be offered as a license package globally by Axens.

Read MoreCorona AFX-2000 Beam-Shaping Laser Boosts Productivity for LPBF Additive Manufacturing

Formnext 2024: The laser’s increased power results in higher productivity and lower cost per part, while maintaining the stability needed to produce high-quality parts.

Read MoreFarrel Pomini Earns EcoVadis Medal

Company recognized for sustainable management system, environmental impact and procurement practices.

Read More