AI Machine Monitoring Arrives from Google Cloud

A new “end-to-end packaged solution” connects shop-floor machine monitoring to the cloud, with AI analytics to turn data into actionable knowledge.

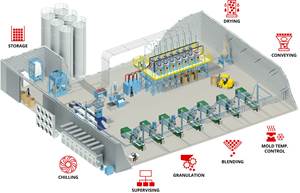

Google Cloud is now extending its data-storage and analytic services down to the shop floor with manufacturing analytics and insights, predictive maintenance and machine-level anomaly detection. (Photo: Google Cloud)

Google Cloud this month is launching two solutions that extend its data-storage and analysis services down to machine monitoring on the manufacturing shop floor. “We are now offering manufacturers an end-to-end packaged solution,” says Charlie Sheridan, technical director of Industry Solutions—Manufacturing for Google Cloud. A primary challenge, he told Plastics Technology, is organizing the vast amounts of data that modern machinery throws off. One function of the new capabilities is to quickly create custom dashboards to visualize key data from factory KPIs (key performance indicators) such as OEE (overall equipment effectiveness) down to individual machine sensor data.

“AI is key,” Sheridan states, to detecting correlations between machine sensor data and other phenomena in order to solve, or prevent, problems with machine availability, productivity or product quality. “Why am I seeing less quality on this machine?” Sheridan asks, as an example of what Google Cloud is now attempting to answer. “We are democratizing AI to provide a low-code or no-code solution for manufacturers.” For example, Sheridan notes that it’s easy to add machines to a monitoring network—they show up automatically on the user’s data dashboard without further customization.

The two new solutions are designed to work together to enable manufacturers to connect “historically siloed assets” (production data stored in different computers and databases) in order to process and standardize data and to improve visibility from the factory floor to the cloud. Once data is harmonized the new offerings enable three critical AI- and analytics-based functionalities: manufacturing analytics and insights, predictive maintenance and machine-level anomaly detection. The last-mentioned function uses AI to learn what constitutes “good” vs. “bad” machine data for process and quality monitoring and for predictive maintenance.

One new solution is the Manufacturing Data Engine, which processes, contextualizes and stores factory data on Google Cloud’s platform. It integrates a variety of Google Cloud products for data storage, access and analysis. The second new offering is Manufacturing Connect, a “factory edge” platform co-developed with Litmus Automation to quickly connect to, and stream data from, nearly any manufacturing equipment and industrial system to Google Cloud. It utilizes a library of more than 250 machine protocols, which encompass most commonly used PLCs. Its deep integration with the Manufacturing Data Engine unlocks rapid data intake into Google Cloud for processing machine and sensor data.

Ford Motor Co. is using Google Cloud to learn how to tweak metal-stamping parameters to maintain consistent quality despite normal variations in sheet-metal materials. (Photo: AdobeStock)

Google Cloud uses system integrators to implement these new solutions at manufacturing plants. Sheridan says it’s now possible to save up to half the normal installation time, so that it can be accomplished in “weeks, not months.” He says the new Google Cloud services are aimed at medium to large enterprises. One of the pilot users is Ford Motor Co., which applied the new tools and AI vision systems to “weighting cause and effect between process parameters,” according to Jason Ryska, Ford’s director of Global Manufacturing Technology Development. In particular, he is using Google Cloud to attack a problem he has been working on since 2004, involving a large metal-stamping line for outer panels of F-150 trucks and transit vehicles. “We take an image of every part on a line that runs 900 parts/hr and 73 million hits/yr. We know there’s variation in the sheet-metal materials, and we can control stamping process parameters. Now we are learning to understand the relationship between the two so that we can hold quality output consistent while responding to variations in any parameter.”

Related Content

A Cost Saving Modular Approach to Resin Drying Automation

Whether implementing a moisture-sensing closed-loop system for a single dryer, or automating an entire plant, technology is available to take the guesswork and worry out of resin drying. Using a modular approach allows processors to start simple and build more capabilities over time.

Read MoreDrones and Injection Molding Ready for Takeoff

Drones and unmanned aerial vehicles (UAV) are approaching an inflection point where their production volumes — and functionality — will increasingly point to injection molding.

Read MoreReal-Time Production Monitoring as Automation

As an injection molder, Windmill Plastics sought an economical production monitoring system that could help it keep tabs on its shop floor. It’s now selling the “very focused” digital supervisor it created, automating many formerly manual tasks.

Read MoreSystem Offers 'Lights Out' Mold-Channel Cleaning & Diagnostics

New system automatically cleans mold-cooling lines—including conformal channels—removing rust and calcium, among other deposits, while simultaneously testing for leaks, measuring flow rate and applying rust inhibitor.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More

(2).jpg;maxWidth=300;quality=90)