Artificial Intelligence Enables Smarter Sourcing

Westfall Technik has adopted Arkestro’s predictive procurement software to wring savings and more reliable deliveries from a historically challenging supply chain.

Built through the acquisition of 17 companies over approximately a 4-year timespan, the company has seen continued solid organic growth from their customers in their target markets of healthcare and consumer packaged goods and continues on their new customer acquisition journey. Westfall’s corporate methodologies backed by their “Stacked Integration Model” certainly delivers as it relates to their value proposition but also has magnified the need for continuous improvement in key areas given its growth. This has resulted in a corporate structure which poses unique and nuanced supply chain challenges. The company provides end-to-end manufacturing capabilities, including product design, moldmaking, injection molding, assembly and more to a broad range of customers, and as David Schultz, VP, Chief Supply Chain Executive puts it, Westfall Technik counts “all the biggest logos” amongst its customers.

Schultz, whose past experience includes several senior operating positions, more specifically, Chief Procurement Officer/Chief Supply Chain Officer for both private and publicly traded companies. He has held key operating roles with GE Plastics, Boston Scientific and ConMed. He was also President and Founder of a packaging business in partnership with Nypro that was later sold following the acquisition of Nypro by Jabil. He began his tenure with Westfall in February 2022 specifically to help the company better steer its myriad of businesses in the same direction from an overall Supply Chain standpoint. After quickly assessing the opportunities to enhance value, he reached out to Edmund Zagorin, CEO of Arkestro (San Francisco), whom he had gotten to know over the years at various supply chain events and conferences. Over that time, Schultz got regular updates from Zagorin on his new company’s capabilities in applying AI/ML to strategic sourcing. Westfall adopted that company’s predictive procurement software in April, initially easing the platform into the company’s sourcing activities. .

“We began with a crawl, walk, run strategy,” Schultz says. At first, Westfall tasked the predictive platform with sourcing so-called indirect materials—things like laptops and security cameras. After these early successes, Westfall and Arkestro transitioned to areas of significantly greater complexity.

“After [indirect materials], we said, ‘Let’s really test this out—work with us on resins, our largest purchases, and extremely complicated direct materials with a lot of moving parts,’” Schultz says. Westfall and Arkestro collaborated to push the platform to where they needed it to be, helping not only with securing lower total costs but ensuring continuity of supply.

“It wasn’t just prices,” Schultz says. “It was capturing the overall value throughout the supply chain. If you look at historical surveys of chief procurement officers, price has always been the top concern. This past year was the first time that it’s not price—it’s Operational Efficiency as underscored in the Deloitte Global 2021 CPO survey. If you get a great price that’s terrific, but if it doesn’t show up, does it really matter?”

Eliminating Human Time Spent Correcting Inevitable Errors

In a non-AI powered procurement process, the heavy lifting of gathering and comparing data falls to people, inviting the inherent possibility of human error and laborious corrective measures. “The classic way procurement teams interact with suppliers is to ask them for a ton of data that’s copy and pasted from multiple systems into a single submission,” Arkestro’s Zagorin explains. “Then on the procurement side of the cycle you create another spreadsheet and look at each row and each offer, side by side, using a pivot table. If there’s an error; if a supplier mis-keys a value in the price; it’s often discovered so late in the process that it can be challenging to catch or update. After all, the error can form part of what has been legally agreed to”

Arkestro’s system works inside of the systems and processes customers are already using by embedding recommendations on price and allocation into a company’s sourcing and purchasing workflows. It does this by recommending predictive pricing suggestions to buyers at the item level for any market basket, Purchase Requisition or Bill of Materials, which can then be communicated directly to suppliers. Arkestro can also route purchases to preferred suppliers and automate buyer-supplier email correspondence, saving time, attention and resources. The company promises to unify a business’s sourcing, purchasing, contracting and supplier management activities with real-time data benchmarks and “manage-by-exception” anomaly detection.

“Arkestro actually recommends price and terms in an offer to a supplier,” Zagorin explains. “Instead of the supplier having to spend time coming up with an offer only to get pushback, not to mention, the procurement team having to screen and rank them all, Arkestro suggests an offer that it thinks is competitive, and the supplier can modify and submit. By proposing a price that’s beneficial to both parties, it shortens the cycle time which gives the supplier greater predictability and the procurement team net-better economics.””

Schultz says Westfall has benefited using the program from the buyer’s perspective, but he has also seen how suppliers quickly gravitate to it as well. “Arkestro initially began the construction of this platform with suppliers in mind,” Schultz says, “and that’s crucial for long-term success. If you don’t have a supplier base that believes in the integrity and simplicity of the system, you’ve got nothing.”

Founded in 2017, Arkestro’s first customer was BASF, with Zagorin noting they’ve “worked on enterprise grade technology from day one,” including the ability to handle data security, global currencies, and more. While those requirements have stayed the same, other aspects of its business have changed.

“Our initial vision was really focused on helping manufacturing and industrial companies nail the RFQ process, where they need to collect and compare quotes for a new product launch, a sourcing event, or approving a large and complex purchase,” Zagorin says.

Early on, the company picked up on the issue of error prone manual data entry. “Web forms with manual text fields alone wouldn’t help much,” Zagorin says. “We realized that from a clean sheet of paper standpoint, you need to apply machine learning, behavioral science and game theory to make sure incentives are aligned. That’s why predictive learning is key.”

In the same way that Netflix or Amazon recommends to users what to watch or buy based on past behavior, Arkesto works to know and understand the companies that deploy it. Where normally, sourcing can get siloed into different groups within the company, Arkestro hopes to open it up. “Traditionally, companies struggle to learn from their own purchasing and procurement transaction history,” Zagorin says. “You buy a replacement part for a machine in one factory, and when you go to buy that same part, you essentially start from scratch. We wanted a recommendation system that learned from purchaser and supplier behavior and makes adaptive well-timed recommendations to suppliers and procurement teams. The fact that the recommendations learn and improve over time is a significant benefit for our customers.”

Could artificial intelligence help you better manage your sourcing process?

Photo Credit: Getty

Related Content

Record Reshoring Rates in 2022

Reshoring and foreign direct investment (FDI) in the third quarter marked their highest ever level, eclipsing the previous record set in the second quarter of 2022.

Read MoreNew Cleanroom-Rated Static Eliminator

Neutralize static hands-free in sensitive medical, pharmaceutical and electronic manufacturing operations.

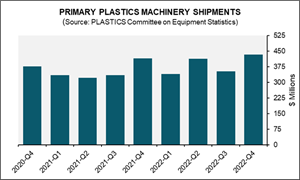

Read MorePlastics Machinery Shipments Rose in 2022’s Final Quarter

The Plastics Industry Association’s (PLASTICS) Committee on Equipment Statistics (CES) reported that injection molding and extrusion machinery shipments totaled $432.7 million in Q4.

Read MoreAsahi Kasei and Mitsui to Collaborate on Biomethanol Supply and Procurement Systems

Asahi will use the biomethanol to produce engineering resins such as acetal.

Read MoreRead Next

Weak Links in the Supply Chain

From pandemic shutdowns to blocked shipping canals, overseas sourcing headaches are forcing many OEMs to rethink far-flung supply chains, particularly when it comes to tooling.

Read MoreCoronavirus and the U.S. Plastics Industry Supply Chain

While we cannot confirm today that the coronavirus has already impacted the U.S. plastics industry supply chain, it is reasonable to expect that if the coronavirus crisis in China continues and escalates, it will negatively impact the U.S. plastics industry. For business continuity reasons, U.S. plastics companies need to look at their current supply chain involving China and—as a precautionary measure—examine alternative supply sources.

Read More

(2).jpg;maxWidth=300;quality=90)