System Simplifies Thread-Repair Insert Installation

NPE2024: C-Sert Manufacturing’s new installation system is designed to speed up the removal of damaged threads and the creation of a new pilot hole — 10 to 15 minutes per hole — with just four components.

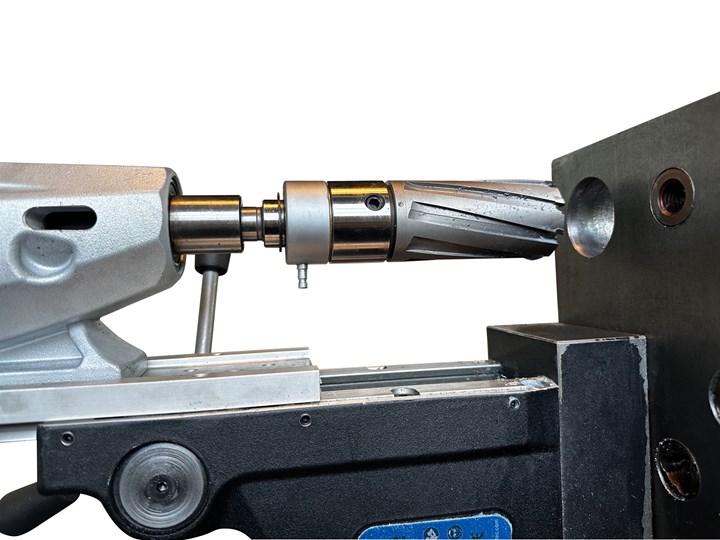

C-Sert’s installation system utilizes a 60-degree center to position the mag drill squarely on the platen hole. Source: C-Sert

C-Sert Manufacturing is introducing a new installation system for its C-sert thread-repair inserts, enabling fast, safe installation on injection molding machine platens. C-Serts are self-tapping inserts made from through-hardened S7 high-impact tool steel for the permanent repair of damaged platen holes, where frequent mold changes and production pressures can lead to stripped threads. C-Serts enable a permanent repair that’s guaranteed for the life of the press against thread wear, pullout and back-out. Self-tapping and self-aligning, C-Serts are designed to install straight.

The new C-Sert installation system can remove damaged threads and create new pilot holes in 10 to 15 minutes per hole. The system consists of four components, starting with a 29-lb German-made magnetic drill. Enabling one-person operation, C-Sert says the drill prevents injuries, minimizes downtime and eliminates the need for 100-lb magnetic drills or overhead cranes.

Next, annular cutters replace traditional drill bits, creating far lower tool pressure so the 29-lb mag drill can open large holes up to 1 ¾ inch. A 60-degree center positions the mag drill squarely on the platen hole, preventing misaligned drilling or drill placement, and the paste coolant replaces a mag drill’s traditional, gravity-fed coolant system. C-Sert says a teaspoon of the paste goes into the hollow annular cutter and melts as the cutter heats up, keeping the coolant on the cutting surface. The company notes that traditional gravity-fed liquid systems can’t accommodate vertical surfaces, such as platens.

In a release, C-Sert owner Carl Strom says his company is making the installation system available at cost for around $1,000, which he says is much less than the price of a single, large magnetic drill.

Annular cutters replace traditional drill bits for lower tool pressure. Source: C-Sert

Related Content

-

A Simpler Way to Calculate Shot Size vs. Barrel Capacity

Let’s take another look at this seemingly dull but oh-so-crucial topic.

-

Know Your Options in Injection Machine Nozzles

Improvements in nozzle design in recent years overcome some of the limitations of previous filter, mixing, and shut-off nozzles.

-

Best Methods of Molding Undercuts

Producing plastics parts with undercuts presents distinct challenges for molders.