'Smart,' Moisture-Based Drying Technology Enhanced

At NPE2024, Novatec relaunches DryerGenie with a goal to putting an end to drying based on time.

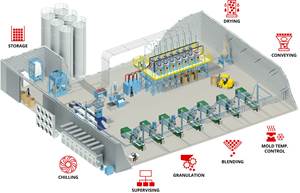

Novatec has reengineered it’s DryerGenie, a system that used sensors to measure resin moisture, and coupled it with new features in its drying hopper to make the process of drying hygroscopic materials more efficient and less dependent on time-based recipes. Novatec took the wraps off the product this month at NPE2024.

Novatec’s first iteration of the DryerGenie was shown for the first time about a year ago, during Plastics Technology’s PTXPO 2023 trade show in Rosemont, Illinois. At the time, the technology utilized sensors placed at the top and bottom of the suction probe or lance that’s typically used by molders to pull resin from gaylords to the dryer to prepare the material for processing. But feedback from processors at that show and thereafter resulted in Novatec rethinking the placement of these delicate sensors, as material handlers generally tend to leave these lances in harm’s way on the plant floor when done with them.

DryerGenie calculates the starting moisture level of the resin to more accurately determine the time it will take the material to dry. Source: Novatec

As a result, in the new, more rugged design, the resin-moisture analyzer is situated below the receiver and directly above the drying hopper. As Mark Haynie, Novatec’s vice president of Moisture and Drying Technology, explains, the moisture analyzer uses the capacitance of the resin to determine the starting moisture level entering the drying hopper. He notes, “The capacitance of water (moisture) is many times that for plastics. By knowing the dielectric constant of the base plastic, the resin with moisture can be accurately determined by the changes that occur with moisture present. This, along with knowing the ambient temperature and relative humidity, allows you to determine the possibility of moisture gain over time.”

But because drying parameters are also based on conditions beyond the initial moisture content of the material, Novatec has taken the DryerGenie a step further by placing a Drying Process Scanner within the hopper. A series of sensors within the drying hopper measure — and adjust as needed — air flow, temperature and dewpoint. Says Haynie, “These measurements and adjustments are necessary for proper drying. The system defines the hopper profile, and the data is used to adjust parameters that are critical to efficient drying. By using the temperature and dew point profile of the drying hopper, you can determine the moisture profile throughout the drying hopper. In combination with a known inlet moisture in the resin, from the resin moisture analyzer, the moisture profile allows you to accurately know the resin moisture exiting the hopper.”

A process scanner inside the drying hopper constantly monitors the process and makes adjustments as needed to airflow, dewpoint and temperature. Source: Novatec

The Drying Genie takes aim at long-held industry “cookbook” practices of drying resin based on time. Novatec CEO Conrad Bessemer, “The first standard we are challenging is drying to the resin supplier’s recommendations that appear on the data sheet. These recommendations are usually very wide: 2-4 hours or 4-6 hours. That’s because by the time the resin reaches the processor, the moisture levels in it may have changed dramatically from when it was shipped and is highly dependent on seasonality.”

Adds Haynie, “Most drying times from resin data sheets include significant safety factors, which result in overdrying, wasted time and wasted power. In most cases, the starting moisture point is unknown. Even two gaylords received the same day can have dramatically different starting moisture points. To that point, we recently received two gaylords of nylon 66 from the same supplier on the same day. One came in at nearly 3,950 ppm, the other at 1,750 ppm. But the supplier’s recommendation for drying time and temperature were the same.”

The second, notes Haynie, is drying to dewpoint levels. “Most processors think drying performance is all about dewpoint. That’s a fallacy,” Haynie says. “Dewpoint is a measurement of the moisture in the air, not pellet moisture. Low dewpoint air is useful in drying plastics, but has nothing to do with the inherit moisture in the pellet. Dewpoint measurements indicate the dryer’s performance, not pellet moisture result. PPM or moisture percentage of the pellet is the only real way to measure dryness of the resin.”

Table 1 With no information on the starting moisture level of the material, following the supplier’s recommendation to dry 4 hours to reach 200 ppm resulted in drying 2 hours longer than necessary.

Throwing away the resin company cookbook and instead relying on real-time moisture readings and dryer adjustments could very well result in increased capacity utilization of molding machines, Novatec argues. At its lab in Baltimore, Novatec ran the same PC/ABS blend with and without the DryerGenie. The drying time recommended by the supplier to reach 200 ppm, from an unknown starting moisture level, was 4 hours (see Table 1).

Table 2 DryerGenie’s target-based drying determined the true residence time need to reach 200 ppm suggested by the resin supplier, cutting the drying time recommended in half to unlock 2 hours of extra production time.

However, with a known starting moisture level recognized by the DryerGenie at 2,520 ppm, reaching the target of 200 rpm took only two hours (Table 2). In addition to overdrying the material in the first scenario, which can result in brittle parts that fail over time, drying the material without a known starting moisture level at the start resulted in a machine that would be making parts to otherwise sit idle for two hours.

Related Content

Streamlined Drying Process Speeds Up Changeovers

NPE2024: Maguire demonstrating increase in productivity possible by vacuum drying.

Read MoreNew Technology Enables ‘Smart Drying’ Based on Resin Moisture

The ‘DryerGenie’ marries drying technology and input moisture measurement with a goal to putting an end to drying based on time.

Read MoreA Cost Saving Modular Approach to Resin Drying Automation

Whether implementing a moisture-sensing closed-loop system for a single dryer, or automating an entire plant, technology is available to take the guesswork and worry out of resin drying. Using a modular approach allows processors to start simple and build more capabilities over time.

Read MoreBlending Specialists ABS Relaunching Thoreson McCosh Dryer Line

NPE2024: Advanced Blending is taking the wraps off reinvigorated Thoreson McCosh drying line.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreRecycling Partners Collaborate to Eliminate Production Scrap Waste at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair will seek to recover and recycle 100% of the parts produced at the show.

Read More