Plastics Industry Automation

Automation in the Plastics Industry involves robots, cobots, molding cells, part pickers, and end-of-arm-tooling.

ESSENTIAL READING

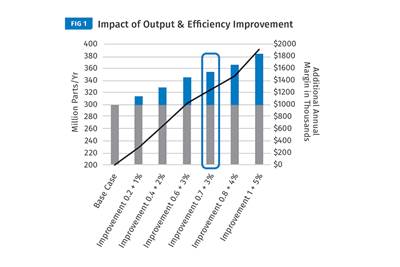

VIEW ALLWhat to Look for in High-Speed Automation for Pipette Production

Automation is a must have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floorspace consumption and payback period.

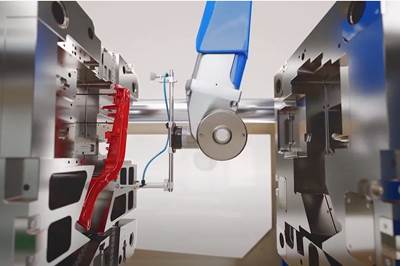

Read MoreHow to Automate High-Precision ‘Micro’ Insert Molding

What does it take to automate a horizontal injection molding cell to handle micro-sized inserts and molded parts? General-purpose top-entry robots and tooling may not be up to the job.

Read MoreHow to Plan and Implement Automation in an Injection Molding Plant

There is no “one size fits all” solution in automation. When considering what it would look like in your plant, hone in on the staff, products, space, and goals that are specific to you and the automation system that you will be installing.

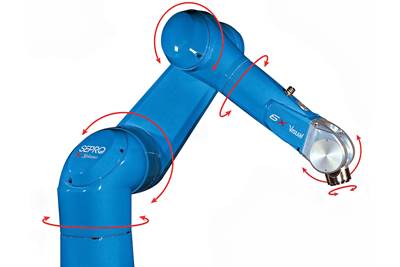

Read MoreAUTOMATION—PART 2 When to Consider Six-Axis Articulated-Arm Robots

Extraordinary versatility suits articulated-arm robots to a wide variety of operations, from loading inserts and unloading parts to decorating, assembly and testing. They also pair well with Cartesian robots. Many mounting options and improved speed and ease of programming add to their flexibility.

Read MoreHow to Make Your Pneumatics ‘Smart’

Emerson’s Avantics Smart Pneumatics Analyzer digitizes the analog pneumatic environment and monitors and analyzes key operating data.

Read MoreImplementing Automation Systems: How to Do It Right

If you’re thinking of putting a complex automation system for high-volume consumables into your plant, consider these tips on making sure both you and your supplier are ready to give it the best chance of success.

Read MoreLatest Automation News And Updates

Cobot Takeout System for Shuttle Machines

NPE2024: Proco Machinery upgrades its Robopik bottle takeout system for shuttle blow molders with the addition of a collaborative robot.

Read MoreYushin America Announces New President

The robotics supplier named Michael Greenhalgh as the new president, taking over the Japanese company’s largest overseas subsidiary.

Read MoreCobot Palletizing System for Bottles

NPE2024: Proco Machinery’s new collaborative robot system palletizes bottles with trays and tier sheets up to 104 in. high.

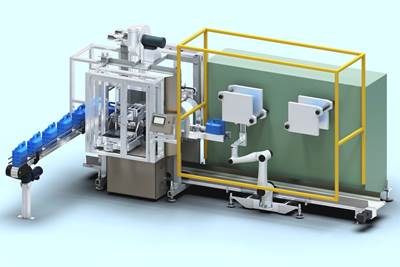

Read MoreThree Robots and 12 Automated Operations in One Cell

Sepro is highlighting a range of automation capabilities in a three-robot cell — including cartesian, articulated arm and cobot units — integrated with a 125-ton Milacron injection molding machine.

Read MoreRobotic Speed and Precision on Display

NPE2024: Sepro’s S5-25 Speed and 5X-25 robots work together in an interactive NPE2024 display to show the company’s range of automation capabilities.

Read MoreSmart Granulator Control Integrates Size-Reduction Systems, Enables Predictive and Knife Maintenance

NPE 2024: Conair’s New SG Control is available for its Viper Granulators

Read MoreFeatured Posts

Automation in Winding, Coiling and Cutting for Reduced Labor and Increased Safety and Consistency

Reel Power will demonstrate how its automatic winding system works in concert with extrusion and automated pick and place.

Read MoreAbsolute Robot Grips New Role as Custom Automation Integrator

NPE2024: ARI exhibit positions robot supplier as integrator of more complex custom downstream automation systems.

Read MoreConnectivity for Material Handling Offers Greater Visibility

NPE2024: Motan solutions integrate data connectivity.

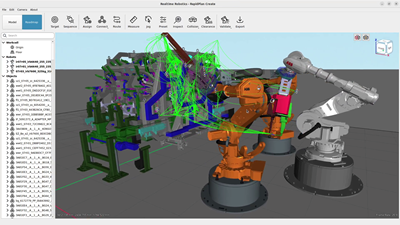

Read MoreDigital Twin Creates New, Virtual Paths for Robots with Real-World Cycle-Time Impacts

Realtime Robotics seeks to get more robots involved in manufacturing by addressing the biggest current barrier: programming costs.

Read MoreProcessing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

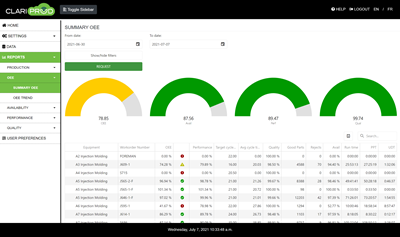

Read MoreReal-Time Production Monitoring as Automation

As an injection molder, Windmill Plastics sought an economical production monitoring system that could help it keep tabs on its shop floor. It’s now selling the “very focused” digital supervisor it created, automating many formerly manual tasks.

Read MoreFAQ: Automation

How to add automation to injection molding?

There is no “one size fits all” solution in automation. When considering what it would look like in your plant, hone in on the staff, products, space, and goals that are specific to you and the automation system that you will be installing.

Automation Supplier Categories

- Rebuilt Screws or Barrels

- Other Testing/Analysis Equipment

- Automation/Systems Integration

- Speed, Drive Controls

- Recording Instruments

- Troubleshooting, Problem Solving Systems

- Technical and Trade Associations

- Machining, Routing Software

- Materials Formulating Systems

- SPC, SQC Systems

- Product & Tool Design, Analysis Software (CAD/CAM/CAE)

- Assembly Robots and EOAT

- Flow Monitoring/Control Devices (for Liquids)

- Training Programs in Plastics

- Maintenance Management Systems

- Timers

- Rebuilt Motors and Drives

- ISO 9000 Software

- Job Quoting, Cost Estimating and Accounting Systems

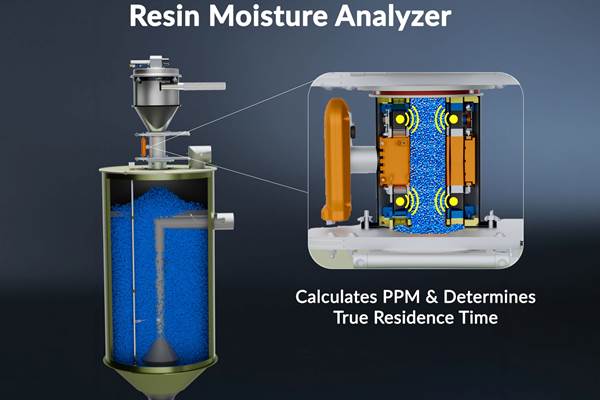

- Dewpoint Monitors/Moisture Analyzers

- Parison Programmers

- Spray Painting Robots and EOAT

- Scheduling, MRP, Production and Inventory Management Systems

- Pressure Controllers, Monitors

- Temperature Controllers, Monitors

- Computer and Automation Testing Auxiliaries

- Color Matching/Formulating Systems

- Temperature Pyrometers, Sensors, Thermocouples

- Design of Experiments (DOE) Software

- Motion or Position Controls

- Part or Sprue Removal Robots and EOAT

- Screw Design/Analysis Software

- Sequence Logic Controls

- Level Sensors and Controls

- Used Molds

- Closed-loop Process Control Systems

- Used Machinery

- Machine Monitoring/Alarm Systems

- Pressure Sensors, Transducers

- General Purpose Robots and EOAT