Industry & Technology News: January 2010

New ‘Green’ Flame Retardant Coming in 2010Additives supplier Albemarle Corp. in Baton Rouge plans to launch a polymeric flame retardant later this year as the first product in a new Earthwise family of “sustainable, eco-friendly products.” All Earthwise products will have been screened for toxicity, bioaccumulation potential, and recyclability.

New ‘Green’ Flame Retardant Coming in 2010

Additives supplier Albemarle Corp. in Baton Rouge plans to launch a polymeric flame retardant later this year as the first product in a new Earthwise family of “sustainable, eco-friendly products.” All Earthwise products will have been screened for toxicity, bioaccumulation potential, and recyclability. Polyurethane curatives are expected to be the second type of additives to join this family.

The first EarthWise product, to be launched in the second half, will be called GreenArmor. Described as a unique brominated polymeric compound, it is distinguished from other polymeric FR agents in its high performance and broad range of applicability, says Albemarle. GreenArmor has been tested successfully in styrenics, polyolefins, nylons, and TP polyesters. It boasts high FR efficiency, comparable to DBDPO or Albemarle’s Saytex 8010. It reportedly also has good thermal stability and is melt blendable, providing good flow and surface quality, as well as good mechanical and thermal properties, to finished compounds.

(800) 535-3030 • earthwiseinside.com

For more information visit Albemarle Corp's PT Online Showroom.

NPE 2012 Moving to Orlando, Fla.

The next NPE international plastics exposition will take place April 1-5, 2012 at the Orange County Convention Center in Orlando, Fla. NPE 2015 will also be in Orlando, but in late March. NPE has been presented by the Society of the Plastics Industry in Chicago’s McCormick Place since 1971, and the event has occurred in June since 1979. SPI said the move will offer big reductions in expenses for exhibitors and attendees—including an average of 48% savings in utilities for booths, 19% in on-site hauling (“drayage”) and rigging services, 23% on lodging, and 11% on travel.

Program changes will include a Sunday opening with educational programs and other special events, as well as just four days—Monday through Thursday—for the show itself. In addition, exhibits will be grouped for the first time by product category.

(202) 974-520 • plasticsindustry.org/goto/NPE2012Venue

Buy Auxiliaries Online

Conair Group Inc., Cranberry Township, Pa., is now offering online purchases of loaders, dryers, chillers, feeders, blenders, mold-temperature control units (TCUs), and Gaylord tilters, as well as used equipment and spare parts. The Conair BuyNow program will include QuickShip items—popular standard equipment stocked for immediate shipment.

For more information visit Conair Group Inc's PT Online Showroom.

Make Polyolefins RF Weldable Without Additives

Up to now, radio-frequency (RF) welding or sealing of films, foams, and fabrics has been limited mainly to polar resins with high dielectric loss factors—particularly flexible PVC and TPU. Nonpolar PE and PP are “invisible” to RF energy unless modified with large amounts of polar additives like EVA, which add cost and negatively affect product properties and processability.

Now there’s a new solution for manufacturers who want to get away from PVC for environmental reasons and don’t want the expense of using TPU. Called ecoGenesis, it’s a proprietary development from Genesis Plastics Welding, Indianapolis, an RF welding/sealing specialist and contract manufacturer. Genesis is offering what it says is an inexpensive modification to standard RF welding hardware along with a know-how license. This “drop-in” solution reportedly is quick and easy for customers to install themselves and it makes unmodified PE and PP “see” RF energy without any glue, coating, or expendable buffer or adhesive layers of another material. It involves no change in RF tooling and no change in RF power or frequency generation.

What’s more, the equipment modification is said to make the RF welding process more stable than usual and to allow welding much thinner materials—down to 0.001 in.—without arc hazard. Genesis will demonstrate ecoGenesis at the Medical Design & Manufacturing (MD&M) West show in Anaheim, Calif., Feb. 9-11 and at MD&M East in N.Y.C. June 8-10.

(317) 485-7887 • genesisplasticswelding.com

For more information visit Genesis Plastics Welding's PT Online Showroom.

Related Content

Compatibilizers Aid Recycling & Upcycling of Mixed Resins

Compatibilizers are proving their worth in boosting critical properties such as impact/stiffness balance of PCR and PIR blends of polyolefins and other plastics.

Read MoreHow to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

Read MorePregis Performance Flexibles: In the ‘Wow’ Business

Pregis went big and bold with investment in a brand-new, state-of-the-art plant and spent big on expanding an existing facility. High-tech lines, well-known leadership and a commitment to sustainability are bringing the “wow” factor to blown film.

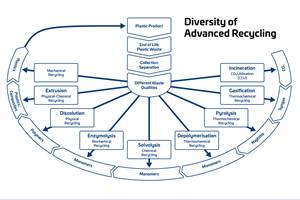

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More

.png;maxWidth=300;quality=90)

(2).jpg;maxWidth=300;quality=90)