Hot Runners for Plastics Production

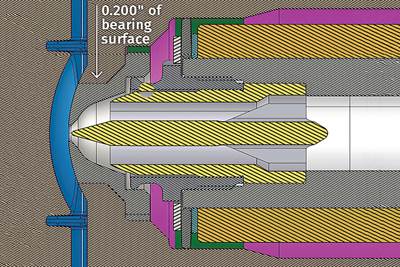

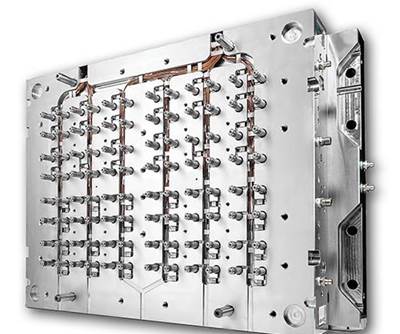

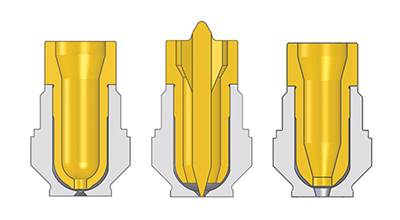

A hot runner system is an assembly of heated components—hot halves, nozzles and gates and—that inject plastic into the cavities of an injection mold. The system usually includes a heated manifold and a number of heated nozzles.

ESSENTIAL READING

VIEW ALLHow to Start a Hot-Runner Mold That Has No Tip Insulators

Here's a method to assist with efficient dark-to-light color changes on hot-runner systems that are hot-tipped.

Read MoreHot Runners: How to Maintain Heaters, Thermocouples, and Controls

I conclude this three-part examination of real-world problems and solutions involving hot runners by focusing on heaters, thermocouples, and controls. Part 3 of 3.

Read MoreHot Runners: Truths. Myths, Overlooked Areas: Part 2

Here’s a view from the trenches of a tooling manager who, over 30 years, has experienced the joys and pains of using virtually every type of hot runner on the market. Part 2.

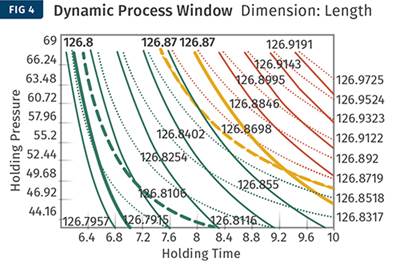

Read MoreHow to Optimize Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Applying a scientific method to what is typically a trial-and-error process. Part 2 of 2.

Read MoreOptimizing Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Using scientific procedures will help you put an end to all that time-consuming trial and error. Part 1 of 2.

Read MoreHot Runners: A View from the Bottom Up

Addressing hot-runner benefits, improvements, and everyday issues from the perspective of decades of experience with probably every brand on the market. Part 1 of 2.

Read MoreLatest Hot Runners News And Updates

Construction Begins on Fully Automated Hot Runner Production Plant

Oerlikon HRSflow will start the construction of a new fully automated plant in San Polo di Piave, Italy, to expand capacity for the growing European market.

Read MoreFast Thermal Reactions for Hot Runner Nozzle

Günther says the compact design of its new BlueFlow heating technology results in a slimmer, more powerful and energy-efficient hot runner nozzle.

Read MoreValve-Gate Sequencer Controls Mold-Filling Sequence

PCS Company has introduced the Polimold Valve Gate sequencer to control the opening and closing of hot runner valve-gate pins.

Read MoreCold Deck for LSR Molding

After field testing, validation and refinement with customer feedback, Husky announced the introduction of a cold-deck system for direct gate molding of LSR.

Read MoreRFID Applied to Hot Runner Systems

Hasco says the adapted variant of the Mold Tag makes it possible to read out all data on the hot half or a wired system directly on a smartphone.

Read MoreInterchangeable Needle Valve Pre-Chamber Simplifies Hot Runner’s Maintenance

Hasco’s Vario Shot Xgate features an interchangeable needle-valve pre-chamber to lower the cost and difficulty of maintenance.

Read MoreFeatured Posts

Hot Runners: How to Maintain Heaters, Thermocouples, and Controls

I conclude this three-part examination of real-world problems and solutions involving hot runners by focusing on heaters, thermocouples, and controls. Part 3 of 3.

Read MoreHot Runners: Truths. Myths, Overlooked Areas: Part 2

Here’s a view from the trenches of a tooling manager who, over 30 years, has experienced the joys and pains of using virtually every type of hot runner on the market. Part 2.

Read MoreHow to Optimize Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Applying a scientific method to what is typically a trial-and-error process. Part 2 of 2.

Read MoreOptimizing Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Using scientific procedures will help you put an end to all that time-consuming trial and error. Part 1 of 2.

Read MoreHot Runners: A View from the Bottom Up

Addressing hot-runner benefits, improvements, and everyday issues from the perspective of decades of experience with probably every brand on the market. Part 1 of 2.

Read MoreHow to Detect and Prevent Hot-Runner Manifold Leaks

Minding the temperature gap at startup between the nozzle and manifold; visually and electronically monitoring signs for leaks; and preventive maintenance between runs can save you from hot-runner leak horror stories.

Read MoreFAQ: Hot Runners

First, think of it as an extension of the molding machine itself. Its purpose is to keep the plastic molten at a proper temperature on its path to the cavity. So basically it’s just a piece of heated steel with a round channel in it for the melt to flow through. Ideally, this channel would be running at the exact temperature on the controller, free of obstacles such as dead spots or components that could create hangups and cause scrap issues with color changes or contamination.

Hot Runners Supplier Categories

- Thermoformers

- Platens

- Nonferrous Metals for Molds

- Injection Molds

- Mold Steels

- Injection Molding Nozzles

- Injection Blow Molds

- Inserts

- Accumulators (Melt)

- Tool Engraving, Texturing Equipment

- Injection Molding Non-return Valves

- Compression/Transfer Molds

- Nonmetallic Tooling Materials

- Hot Runner Components

- Compression/Transfer Presses

.png;maxWidth=300;quality=90)