Molder Puts the ‘Art’ into Decorating

Processor Strategies: Plastic Parts Inc.

Custom molder took its expertise in in-mold coloring, IML, and IMD to the next level with the launch of a new division, Artistry of Plastics. The operation utilizes a proprietary technique, trade named Fabric Fusion, which merges resins with textiles to create a unique seamless product design.

Plastic Parts Inc. is a 47-year-old family-owned business that runs 17 injection presses in a 44,000 ft² facility in Union Grove, Wis. The firm is a disciple of “scientific molding” and its wide range of capabilities include insert molding, overmolding, gas-assist molding and plating. The custom molder participates in a wide range of end markets, including transportation, heavy equipment, and lawn and garden.

“We have a positive attitude about doing new things,” states v.p. Jill Osiecki, part of the second-generation ownership team, along with sister Sharon Jorgenson, Plastic Parts president; brother Jeff Jorgenson, general manager; and husband Chris, manager of finance and administration. She cites one instance when Plastic Parts took in a mold that a large, well-known molder could not properly fill. After a few tooling and process modifications, Plastic Parts was not only producing the part—an engine stator for a motor manufacturer that was insert overmolded—it was making it with such precision that the OEM saw its warranty rate drop from 14% to less than 1%.

Given this willingness to venture out of its comfort zone, it’s not surprising that that Wisconsin molder would look to take its expertise in in-mold coloring, IML, and IMD to the next level with the launch of a new division, Artistry of Plastics. Named after Plastic Parts founder Arthur Jorgenson, Jr., the operation utilizes a proprietary technique, trade named Fabric Fusion, which merges resins with textiles to create a unique seamless product design. The new venture was launched to nurture a plastics decorating method the business owners saw lacking in an industry dominated by textured mold styles that were created for industrial designs with masculine appeal.

Fabric Fusion combines the style and texture of fabrics in a way that traditional printed labels cannot match and offers the versatility of using a multitude of textiles with custom decoration techniques, including embroidery stitching, laser embossing and debossing, according to Osiecki.

The venture came about when entrepreneur Kathleen Quinn, president of Dallas-based K. Quinn Designs, was looking for a way to make plastic storage cases fashionable. Her design concept—a container for personal-hygiene wipes—needed to appeal to a market that would appreciate a high-design, reusable case. The effort to make the concept a reality presented a challenging opportunity because there was nothing like it on the market.

After writing a provisional patent for a plastic case that would have a substantial feel, be easy to clutch, and have a durable decoration with feminine appeal, Quinn sought to find someone who could make it come alive. That search lead her to Plastic Parts, which Jill Osiecki had recently joined.

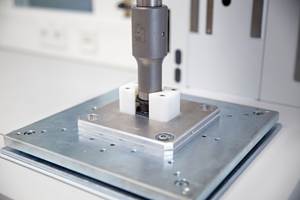

Led by Jeff Jorgenson, the Plastic Parts tooling department first built a single-cavity mold engineered to reliably and repeatedly accept a fabric insert for a part with a living hinge. The company then worked on selecting a resin that would work for the entire design line. They reviewed six different resins, and tested numerous colors and metallics, ultimately selecting a black polypropylene.

The resulting fabric label—fabric fused with a proprietary backing—was developed to load into a robotic end-of-arm assembly. According to Osiecki, the extreme accuracy of the adhesion process was achieved through numerous adaptations and relentless testing. The automated method was the final step in achieving the unique molded-in technique that merges resins with textiles to create a seamless product design.

These efforts reaped immediate rewards for K. Quinn Designs. Quinn’s products can now be found in more than 70 Buy Buy Baby stores nationwide. Quinn and Osiecki already are collaborating on ideas to expand the product line with slimmer, sleeker cases.

Related Content

Can Plastic Recyclates be Welded Ultrasonically?

What is possible with ultrasound? Will the result with recycled plastics material actually be worse than with standard material? Do we have to adapt our technology?

Read MoreAutomation in Thermoforming on the Rise

Equipment suppliers’ latest innovations exemplify this trend driven by factors such as labor shortages, higher-speed thermoformers and tighter quality control.

Read MoreSustainable Materials is Focus of Thermoforming Exhibits at K 2022

Thermoforming equipment makers including WM, Kiefel, and OMV will showcase processing of recyclable and biobased materials.

Read MoreMinnesota-Based Initiative Launches Circular Economy for Flexible Films in Upper Midwest

MBOLD coalition unites leading global businesses and research institutions to catalyze a regional circular economy for flexible films and packaging materials.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read More