NPE 2006 News Flash

Injection MoldingSimplified Hot Runners Save Time & CostA new lower-cost hot-runner alternative to valve gating is suited to less critical cosmetic applications where users need predictable and reliable gate opening but not sequential gate operation.

- Postindustrial

- Gas & Water Assist

- Extrusion

- Additives

- Resin Conveying

- Tooling

- Pipe, Profile & Tubing Extrusion

- All Electric & Hybrid Machines

- Testing

- Recycling

- sustainability

- Mold Simulation

- Compounding

- Purging Compounds

- Film Extrusion

- Injection Molding

- Postconsumer

- Molds & Tooling

- Multiscrew

- Hot Runners

- monitoring

Injection Molding

Simplified Hot Runners Save Time & Cost

A new lower-cost hot-runner alternative to valve gating is suited to less critical cosmetic applications where users need predictable and reliable gate opening but not sequential gate operation. The new Control Gate system from Incoe Corp., Troy, Mich., features a spring-loaded design and pneumatics for gate operation. Control gates are opened by spring action against a piston and cylinder design. Closing is accomplished by applying pneumatic pressure to the full surface area of the piston, thus compressing the spring. This design reduces the number of components and the cost as compared with a valve-gate system that uses pneumatics or hydraulics for both the opening and closing valve movements.

Incoe will also introduce at NPE a water-cooled gate insert that requires minimal installation effort for the moldmaker. Also new is a system that combines two heaters in one nozzle heater coil to provide redundancy in case one heater fails, while maintaining the same dimensions as previous Incoe nozzle heaters and interchangeability with those designs. Incoe says this system is unlike other systems with two independent heater coils wound on the nozzle body, which interfere with proper heat profiling.

Share & Compare Moldflow Results for Free

Moldflow Communicator 1.0 is a brand-new software program that lets companies share and compare Moldflow analysis results among users who may not have the actual analysis software. The Windows-based PC program can be downloaded for free via the internet from Moldflow Corp., Wayland, Mass. It communicates analysis results to all members of a development team, such as moldmakers, molders, and OEM design engineers.

Users can view 3D models and animations of analysis results and can rotate, pan, zoom, and split the model dynamically. Users can overlay more than one result at a time on the same model, such as fill time and air traps, weld lines, or core/skin orientation.

Most important, says Moldflow, is the ability to verify the quality of analyses performed. It lets users compare simulation results of two iterations in a side-by-side fashion. The two displays can be “locked” to synchronize rotation, zoom, animation, etc. Users also can compare simulation results with predetermined quality criteria in the form of a numerical table. Variations from those criteria are highlighted automatically.

The software supports analysis results exported as a compressed file via e-mail from Moldflow Plastics Insight (MPI) 6.0 simulation software. Future versions will also support results from Moldflow Plastics Advisers (MPA) software.

Multi-Nozzle Presses for Large Foam or Solid Parts

A large-platen press series suitable for gas-assist or structural-foam molding of large parts will be unveiled by Wilmington Machinery, Wilmington, N.C. Its new Lumina LP series comes with platen sizes up to 110 x 200 in. and shot capacities to 300 lb. The line has Wilmington’s new Versafil independent nozzle control, which makes it easy to configure the machine for sequential filling. The system also features an improved five-cylinder clamp system that reportedly makes it easier to convert the press from structural-foam to gas-assist processing. The nozzles have been redesigned and access to them improved to reduce mold-change and setup times.

Wilmington will also unveil its NextGen series of large-platen machines for molding large solid and foam parts weighing up to 150 lb. These two-platen units feature AC vector-driven single or dual extruders, combined with two-stage hydraulic accumulator injection.

Small Hybrid-Electric Press

A new 61-ton hybrid injection press featuring electric plastication with hydraulic clamping and injection will make its North American debut from Boy Machines Inc., Exton, Pa. The Boy 55Ae model features ejection on the fly, achievable through use of a double-pump system. The design is said to be especially efficient in molding screw caps, where tests have shown cycle-time reductions up to 11%.

New Two-Platen Machine Style

New models in the large two-platen Titan series will be shown in North America for the first time by Demag Plastics Group (DPG) Strongsville, Ohio. It will demonstrate a Titan 1500 (1500-ton) press molding a Roush Racing front spoiler for a Ford F-150 pickup with the aid of a Kuka six-axis robot. A new Titan 1100 will mold a multi-component automotive part.

In addition, in-mold labeling will be shown for the first time at NPE on a 615-ton El-Exis hybrid toggle press. The press will mold a decorated container with lid in a 1+1 cavity mold.

Electric Press for LSR

Three models of Canbel VE all-electric pres ses will represent the U.S. debut of this upgrad ed series from Negri Bossi USA, Newark, Del. As we first reported last month, Can bel replaces the Elma line and has been upgraded for faster injection, more precise and repeatable movements and reduced maintenance. Horizontal toggle presses will be represented by 480- and 528-ton models. Also new will be Negri Bossi’s first all-electric LSR machine, a 77-ton Canbel VE 70 mo del, which will produce a syringe plunger assembly at the show.

Extrusion

Keep an Eye (or 4 Eyes) On Your Film Line

Monitoring blown and cast film lines with multiple video cameras is a cost-effective troubleshooting and supervisory technique, according to Macro Engineering & Technology Inc., Mississauga, Ont. Macro de veloped the concept years ago for highly sensitive PVDC blown film lines, which took as many as three operators to start up and were tricky to operate. Now Macro offers the supervisory recording system to other processors for $22,000 with four cameras and software. Extra cameras are $500 each. A typical blown film system uses four cameras to watch the die, winders, oscillating nip, and edge trimming. Extra cameras could observe fill levels in hoppers.

The big advantage is that one operator can keep track of a half-dozen extrusion lines with split-screen viewing. For example, operators can spot problems in nips or gusseting without having to climb the tower in hot summer weather. Cameras also make start-up safer, showing that operators are not in the way of nips or winders as gaps close. They also store a record so that if a bubble comes down, operators can review exactly what went wrong. Macro has a half-dozen systems running in blown film and is now building a 30-camera installation for a complex cast film line. A six-camera installation on a blown film line in Macro’s lab will be shown on a video monitor at NPE.

First North American Extruder with Gearless Torque Motor

Davis-Standard LLC in Pawcatuck, Conn., will show its new gearless EMDD (electric-motor, direct-drive) extruder with a synchronous torque motor for the first time at NPE. It’s believed to be the first use of these quiet, energy-efficient, low-maintenance motors on an extruder designed and built in North America. On exhibit will be a 75-mm extruder with a Siemens motor providing 7000 Nm of torque. After the show, the extruder will be used on a blown film line for customer trials at Davis-Standard’s Somerville, N.J., lab. A 90-mm prototype appeared at the K 2004 show in Dusseldorf. EMDD extruders are now available in six models from 1.5- to 4-in. diam. with up to 7000 Nm torque.

Davis-Standard will show a second new extruder line at NPE, which is notable for its compactness and low cost. Its HyPE (high-performance extruder) models are 30% more compact than previous Blue Ribbon models because HyPE uses a close-coupled gearbox and AC motor to replace a more complex worm gear and belt-drive assembly. HyPE mo dels have ei ther fixed ho r i zontal or ad justable (co extruder) configurations in five sizes from 0.75 to 1.75 in. Built with standard components, they’re less expensive and available for delivery in under two weeks.

First Wireless Roll Cart

This wireless, battery-operated roll-handling cart from Brampton Engineering Inc., Brampton, Ont., eliminates manual shaft removal. It is believed to be the only one of its type on the market. It moves on tracks to four positions, picking up film rolls from face-to-face winders, taking the roll off the shaft and transporting the roll to a dolly or roll stand, then tilting to unload the roll. In home position, the cart automatically recharges while it waits for the next roll. This model weighs rolls automatically. It can handle all standard BE winder roll sizes up to 40-in. diam., 64-in. layflat, and 3000 lb.

A prototype cart will be shown for the first time at NPE.

Biaxially Stretch Practically Anything

The latest lab machine for biaxial film stretching from Bruckner Inc., Greenville, S.C., is configured with three ovens instead of two, allowing it to simulate product development with a sequence of three different oven temperatures. Oven number one heats and stretches; oven number two stretches and anneals; oven number three anneals and relaxes. Three ovens are optimal for biaxial film development in general, but are required to stretch some specialty materials like PLA, cyclic olefin copolymers, PVOH, polyimide, PTFE, and triacetate. Biaxially stretched polyimide is used on circuit boards and can withstand temperatures up to 572 F. Biax triacetate, made by only a couple of companies in the world, is for flat panel displays. Bruckner’s Karo IV lab machine will demonstrate stretching some of these exotic new films at NPE.

First Demo of 80%-Wood Profile Extrusion

The European approach to wood/plastic composites (WPCs) involves extruding very complex profile shapes out of 75% to 85% wood-filled polyolefins for interior applications. It also involves incorporating moisture instead of avoiding it. Otherwise, a few months after a WPC door jamb, for example, is installed, it would start to swell and warp. Cincinnati Extrusion from Vienna (U.S. offices in Erlanger, Ky.) will run a Tital 58 conical lab line at NPE for the first North American demonstration of an 80%-wood PP profile. It will process pelletized compound from Fasalex GmbH in Kopfing, Austria. Fasalex will also be at the booth.

Blow Molding

Recip-Screw Machine Has More Cavities & Output

Rocheleau Tool & Die, Fitchburg, Mass., has added a larger and higher-output machine to its reciprocating-screw blow molding line for lightweight, wide-mouth containers. Model RS70 expands cavitation from 8 to 10, boosts output by 25%, and reduces cycle time by 1 sec, the company says.

The new machine targets 38- to 110-mm containers up to 16 oz. Its automated takeaway and trimming utilize a combination of electric drives and pneumatics for high speed, precision, and durability, according to President Steven Rocheleau. The machine produces 8-oz HDPE milk bottles at 6000/hr.

Deformable Die Ring Makes U.S. Debut

At NPE next month an accumulator-head blow molding machine from Davis-Standard Blow Molding Systems, Somerville, N.J., will feature the new 3DX deformable die-ring technology from BMC Controls Ltd., Winchcombe, Gloucestershire, U.K. Davis-Standard will offer it as an option on its line of accumulator-head machines. This is the first use of the system in the U.S. It controls material distribution in large parts and is said to reduce cost and improve reliability.

The 3DX technology will be shown on an 8-lb head for pro duction of large in dus trial containers. It has a special mounting method to protect the cylinder seals from the head’s heat, as well as a new hydraulic safety function to prevent damage to the flexible die ring on accidental cold starts and a proportional push-out mechanism to improve machine efficiency. Unlike competitive systems, a unique limit-stop system enables users to strip and reassemble the die ring themselves.

Compounding

More Free Volume, No Less Torque

A splined shaft allows Leistritz of Somerville, N.J., to transfer the same amount of torque in its new ZSE Maxx twin-screw compounders—even with a thinner shaft—as in its previous ZSE HP (high performance) series. The Maxx screws have a high OD/ID ratio of 1.66:1 vs. the typical 1.55:1, providing 30% more free volume. Barrel cooling capability is also increased to accommodate the higher volume of material transported by the screws. NPE will be the first appearance in North America for the Maxx line, which was introduced at the K 2004 show in Germany. The Maxx series ranges from 28 to 140 mm diam.

Carbide Coating Insulates Pelletizer Die

An energy-saving underwater pelletizer with a new carbide-coated die plate will be introduced at NPE in Chicago next month. Developed by Econ GmbH, Pasching, Austria, the die plate uses a thin (less than 0.5-mm) layer of abrasion-resistant and heat-insulating Ceconid tungsten carbide to minimize heat losses to the process water, which is said to reduce die heating requirements by more than 70%. Even more energy is saved because the water bath requires less cooling, says Econ. And because the melt is hotter and therefore softer when it is cut, less energy reportedly is required for the motor drive, and knife life is extended.

The Ceconid insulation is said to prevent die-hole freeze-off despite throughput fluctuations as great as 7 to 110 lb/hr per die hole. It also reportedly makes it easier to start up the pelletizer at only 10% to 20% of full production speed.

New Clear or Colored Medical-Grade Materials

Several new materials for medical devices will be unveiled at NPE by Bayer MaterialScience, Pittsburgh. Among them is Texin DP7-1198, a clear, aromatic polyether-based TPU with a 65 Shore D hardness for injection and extrusion applications such as catheters, tubing, and connectors. Usable for implants of 30 days or less, it is biocompatible, resistant to body fluids, and sterilizable with radiation, ethylene oxide, or dry heat.

Bayer will also introduce Makrofol LP 209, a clear polycarbonate film with special additives to withstand gamma and E-beam sterilization without yellowing. Potential applications include titration plates, instrument boxes, and packaging for implants. The film is available in standard thicknesses between 175 and 500 microns.

Bayer will also launch its Fantasia colors and special-effects compounds for the medical market. Select colors for polycarbonates meet the requirements of the FDA-modified ISO 10933, Part I test for biocompatibility. Other colors and special effects do not meet compatibility specs but are usable for medical housings.

Additives

Purging Agents: Just a Pinch Will Do

Fast purging of screws, barrels, and nozzles is reportedly possible with small amounts of chemical purging compounds newly available in North America from Chem-Trend, Howell, Mich. Lusin Clean compounds are said to have a proven history of purging injection, extrusion, and blow molding machines in Europe. These granular, low-odor, low-smoke compounds contain neither fillers nor abrasives, which reportedly makes them particularly well suited to cleaning hot-runner systems, regardless of gate size.

In fact, the newest members of this line, grades G315 and G320, are designed specifically for injection machines and hot runners. G315 is tailored for purging polyolefins and has an operating temperature range of 338 to 599 F. Typical use level would range from 18 lb for a 60-mm screw to 46 lb for a 160-mm screw. G320 is recommended for purging a wide range of engineering thermoplastics as well as polyolefins. It can handle operating temperatures of 356 to 606 F and is specially adapted for cleaning large machines. Expected usage rate ranges from 3 lb for a 60-mm screw to 33 lb for a 140-mm screw.

Carbon Blacks for Food Packaging & Pipe

New specialty carbon blacks for critical food contact and pressure pipe are being introduced by Cabot Corp., Boston, Mass. Black Pearls 4350 and 4750 are high-purity furnace blacks that comply with FDA standards for indirect contact with food.

Elftex P100 is Cabot’s newest P-Type carbon black for pressure pipe used in potable water and gas distribution, as well as irrigation and utility pipe and geomembranes. It boasts excellent UV absorption, chemical and physical cleanliness, good organoleptic properties, low compound moisture absorption, and good processability for smoother surfaces.

Testing & Measuring

Wall-Thickness Gauge with Integral Signal Processing

A non-destructive instrument for measuring wall thickness of bottles, containers, molded parts, hoses, and tubes boasts improved accuracy and reproducibility. The new MiniTest FH 7000 Series probes from ElektroPhysik USA, Arlington Heights, Ill., utilize the magnetostatic principle with sensor-integrated digital signal processing. Processing measurement signals within the sensor eliminates errors that can arise during transfer over cables from the sensor to a remote signal processor.

The FH 7000 also features menu-driven operation that follows a PC-format logic path with context-sensitive help screens. Users can read the actual reading along with min/max limits on the large display. Optional software includes job and user identification, time and date stamps, and real-time graphic display of readings.

The FH 7000 supersedes the earlier FH 2100 and 4100 models and provides much faster scan rates—up to 20 measurements/sec—as well as greater memory capacity. Two sensors offer measuring ranges of zero to 0.160 or 0.400 in. A complete system includes a removable rubber housing with support easel, supply of target balls, calibration standards, sensor stand, carrying case, and batteries.

Process/Production Monitoring

Plantwide Monitoring with RFID & ERP Support

ProHelp EPM 7.0, the latest process-monitoring software from Mattec Corp., Loveland, Ohio, provides support for RFID or barcode labels, JIT production scheduling, and seamless integration with advanced ERP systems. The system automatically generates RFID tags or barcode labels with unique serial numbers for each part or box of parts. Using a separate reader, users can retrieve stored data, including process parameters and SPC charts for each box. The monitoring system runs on Microsoft Windows Server. It monitors every cycle of every connected machine in a plant and alerts user to changes in process conditions.

The ProHelp real-time display provides visual status of processing machines with machine-like icons. Other features include graphical plant-floor displays, data integration with CMS Software’s ERP system (p. 119), enhanced cavity-pressure graphing, and more charting and configuration choices.

Materials Handling

Three-Component Drying, Blending & Conveying

A new stand-alone, three-hopper system allows setting individual drying parameters for virgin resin, regrind, and colorant, and then mixes and conveys the components on demand. The PDIII system from Dri-Air Industries, East Windsor, Conn., eliminates potential waste from making premixed batches that take up storage space and may never be used. In addition, drying all three components together can cause degradation of more sensitive components or incomplete drying of some components.

The space-saving, one-frame design includes Dri-Air’s volumetric mixing (variable- and fixed-rate) augers under each hopper. Resins are dispensed into a common takeoff box and conveyed with dry air to prevent regaining moisture. With its sealed mixing chamber, the PDIII is said to be suited to clean-room environments.

Self-Contained Loaders For Low to Medium Output

A new line of self-contained vacuum loaders is said to be cost-effective for single or dual material conveying at low to medium throughputs. Feedmax IMX 200 and 300 Series integral loaders from Wittmann, Inc., Torrington, Conn., include many standard features common to the company’s Feedmax FMX central vacuum loaders, such as a modular design with stainless-steel contact surfaces, tool-less assembly, positive material-discharge shutoff, and automa tic self-cleaning filters.

The new loaders have capacities of 0.14 to 0.85 ft3 and conveying rates up to 400 lb/hr for the IMX 200 and 800 lb/hr for the IMX 300.

These units have simple controls and 110 V electrical requirement that allows for fast, simple installation. The motor is easily detached with three quick-release toggle clamps that provide fast access for material changes and cleaning.

Guided-Wave Radar Senses Bulk Solids Levels

A new level transmitter uses guided-wave radar for measurement of challenging bulk solids. The WaveTrack 5200 will be featured at NPE by ASI Instruments, Inc., Houston. It is a two-wire, loop-powered device that reportedly is unaffected by dust or feed flow, and accurately de tects materials with bulk densities up to 50 pcf and dielectric constants as low as 1.3. A concentric waveguide directs the radar signal to alleviate problems of beam spreading and echoes from tank walls and internal structures.

First All-Stainless Color Feeder

A new color-concentrate feeder is said to be the first and only such device built entirely from stainless steel, including the easy-to-change auger screw and sleeve. Faster cleaning is said to result, which can save up to 75 production hours a year, according to the supplier, Comet Automation Systems, Inc., Dayton, Ohio. For high accuracy and repeatability, the stepper motor for the auger has increments of 1% of a revolution. The Color Xpert feeder has easy-to-use menu-driven controls, and the controller can be removed and mount ed on the processing machine to make it easier to change settings.

‘World’s Largest’ Weigh Blender

Maguire Products, Aston, Pa., will introduce what it calls the world’s largest batch gravimetric blender, aimed at compounders and other large-volume processors and capable of running pellets at 10,000 lb/hr. That’s double the throughput of Maguire’s next largest blender, and the unit’s batch size (66 lb) is 67% larger.

The MaxiBatch HT is a companion to the original Maxi Batch blender, which was designed for wood flour and other bulk powders. Like that model, the new HT blender can handle up to 12 ingredients, not necessarily in pellet form. To handle pellets at high rates, the major-ingredient hoppers have a new “corner valve” that provides a large opening into the weigh chamber. The valve can dispense at up to 24.2 lb/sec.

New Blender Controls

Two new controls for gravimetric blenders will be shown by AEC, Inc., Wood Dale, Ill. The A3 software package for AEC’s BD series batch weigh blenders for molding machines can handle up to 1000 blenders and 1000 resins and silos or bins. A “virtual control panel” allows starting and stopping blenders, changing recipes, and monitoring blenders and inventories from a single remote PC. An unlimited number of recipes can be stored, and statistical analyses of blender performance can be generated. A Job Report Manager writes reports by job rather than time, showing material usage, batch data, uptime percentage, and alarm logs.

In addition, AEC’s OL series continuous loss-in-weight blenders for extrusion have a new Allen-Bradley controller with color touchscreen, animated graphics, and error-checking software that is exclusive to AEC.

Heating/Cooling

Mold-Temp Controllers From a New Source

Motan Inc., Plainwell, Mich., has supplemented its materials-handling equipment with a new line of water and oil mold-temperature controllers, called Motemp. They include hot-water, pressurized water, and oil temperature-control units covering a range from 90 to 300 C (195 to 575 F). Hot-water units have suction and leak-stop operation as standard. Three levels of controls are offered. Also new is a descaling unit, available with a chemical descaling agent and a corrosion inhibitor for water and steam units, as well as a system cleaner for hot-oil controllers.

Cooling Towers: Steel or Plastic?

Mokon, Buffalo, N.Y., will in troduce a line of cooling towers to complement its line of circulating liquid temperature-control systems. The towers come in galvanized steel or HDPE. Capacities are from 10 tons on up. Steel towers are induced-draft, cross-flow type with a gravity-flow water distribution system.

Plastic towers are forced-draft (up to 100 tons) or induced-draft (100 tons and larger) with PVC water-distribution system and fill. HDPE towers also have an air-moving system with a totally enclosed motor and a drift eliminator.

Scrap Reclaim

Small, Quiet Press-Side Granulators

A new series of compact, low-speed granulators for sprues, runners, and small parts will be shown by Conair, Pittsburgh. The NCR Series come in standard, low-height, and tall models—the last make all key components reachable without bending and also accommodate a larger regrind bin. The tangential-feed cutting chamber ranges from 6 x 6 in. to 6 x 17 in., and overall footprint is 23.6 in. deep by 16 to 26 in. wide. Rotor speeds are 190 to 225 rpm with up to 18 staggered, cassette-type knives. Throughputs range from 40 to 145 lb/hr. These units are said to save energy with a 3-hp motor (5-hp optional).

Related Content

A Recycling Plant, Renewed

Reinvention is essential at Capital Polymers, a toll recycler that has completely transformed its operation in a short period of time.

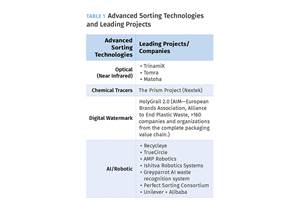

Read MoreRecycling: What's Ahead in Advanced Sorting Technology

As the industry tries to ramp up recycling, there are several innovative sorting solutions in the offing—ranging from enhanced optical sorting technologies and chemical tracers to advanced solutions based digital watermarks and artificial intelligence.

Read MoreRevalyu Breaks Ground on PET Recycling Facility in Georgia

Company expects new facility will be capable of chemically recycling 200 million pounds of post consumer PET per year.

Read MoreNew Facility Refreshes Post-Consumer PP by Washing Out Additives, Contaminants

PureCycle prepares to scale up its novel solvent recycling approach as new facility nears completion.

Read MoreRead Next

How Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More