NPE2018 New Technology Focus: Single-Screw Extruders

What's new at the plastics industry's big trade show in single-screw extruders.

Davis-Standard (Booth W5947) is running TPE tubing line that shows the benefits of preventive and predictive maintenance as part of a global trend toward the “smart factory.” The line is processing TPE tubing for industrial applications and will feature the company’s newest Thermatic extruder design along with the DS eVUE II controller.

D-S is also showing a next-generation 2.5-in., direct-drive, grooved-feed extruder featuring its proprietary Helibar design. The Helibar design is also said to be advantageous in terms of higher throughput, improved melt-pressure buildup, lower melt temperatures, improved melt homogeneity, reduced barrel wear, and shorter residence time. This extruder is said to be suited for pipe, profile, sheet, and blow molding.

The Super Blue extruder line is also featured at the show. D-S says this extruder series offers processors the ability to switch among D-S feedscrews while offering a low-noise, a double-reduction gearbox, minimal maintenance, and consistent production rates. It is available in sizes from 2 to 4.5 in., each with the option of a 24:1 or 30:1 L/D. At the booth, the Super Blue is equipped with the DS-eTPC II, the second generation of Davis-Standard’s touchscreen control.

Graham Engineering Corp. (Booth W2743) is displaying a 2.5-in. (63.5-mm) American Kuhne Ultra extruder with XC100 Navigator control, and a 3.5-in. (99-mm) extruder with XC200 Navigator control. Graham has made improvements to its Ultra extruders to simplify maintenance. Examples are newly designed barrel covers that allow for quick and easy access to barrel heaters and thermocouples, and an automotive-style wiring harness with quick-change plugs for routing wiring and thermocouples from the electrical cabinet to the barrel-heater/cooling zones.

Graham is also showcasing an American KuhneGraham Kuhne three-layer medical tubing line, consisting of modular micro extruders, an American AKcent coextruder, and XC300 Navigator with integrated TwinCAT Scope View high-speed data-acquisition system.

Newcomer US Extruders (S32133) is showing a new generation of highly engineered, custom single-screw extruders. On display are 2.5-in., 24:1 and 3.5-in., 24:1 extruders, as well as a compact custom medical extruder. The 2.5-and 3.5-in. extruders feature a unique heater-shroud design made of individual stainless-steel shrouds that provide quick access to each zone. Dual-layer stainless steel keeps the exterior relatively cool to the touch. Thermocouples go through the side for easy replacement. Each shroud includes an adjustable exhaust deflector. Integral wireways are also built in to provide a clean look and easy access to wires. The machines on display will also have a C-clamp with an easy-open, over-center lever and thumb-release safety lock.

A compact custom medical extruder at the booth includes a servo drive, swappable barrels, washdown design, integrated control cabinet with special die-wiring management, and other special features designed for the medical and pharmaceutical industries. The machine has swappable barrels in 0.50-, 0.75-, and 1-in. sizes.

New from Milacron Extrusion Technologies (Booth W2703), the SV350 is billed as a robust and flexible extruder suited for processors of profile, tubing, sheet, fiber, wire and cable. The SV350 is available in sizes from 2 to 4.5 in. with 24:1 L/D. As a stock machine, it is available for quick delivery.

The solEX NG from Battenfeld-Cincinnati (Booth W2771), offers up to 20% higher outputs, up to 15% lower energy costs, and approximately 15-20° F lower melt temperatures, the machine builder says. Lower melt temperatures allow polyolefin pipe producers to either shorten the length of their downstream cooling system or maintain the same length to boost output by as much as 20%.

Related Content

Formulating LLDPE/LDPE Blends For Abuse–Resistant Blown Film

A new study shows how the type and amount of LDPE in blends with LLDPE affect the processing and strength/toughness properties of blown film. Data are shown for both LDPE-rich and LLDPE-rich blends.

Read MoreWhy Compression Ratio is Important

Compression ratios have been pretty much standardized over the years, based on what has typically worked before. But there are quite a few variables that must be considered in order to get the optimum performance from your screw.

Read MoreAvoid Four Common Traps In Granulation

Today, more than ever, granulation is an important step in the total production process. Our expert explains a few of the many common traps to avoid when thinking about granulators

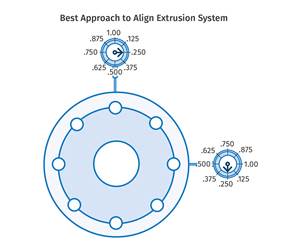

Read MoreExtruder Alignment: Important, but Only Half the Equation

The other half? Aligning and supporting downstream equipment. Here are best practices.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read More

(2).jpg;maxWidth=300;quality=90)