Sort Plastic Scrap Fast By Resin, Color & Additives

Recyclers of mixed plastics waste can detect materials containing flame retardants, heavy-metal additives, and fillers--or they can sort bottles at high rates by color or by polymer--thanks to new technologies unveiled at the second annual Identiplast Conference held recently in Brussels, Belgium. The three-day conference was organized by the Association of Plastics Manufacturers in Europe, the American Plastics Council, (Washington, D.C.), the European Plastics Converters, and the Japanese Plastic Waste Management Institute.

Sort by resin or color

The trouble with around 90% of today's equipment for sorting and separating colored bottles from clear is that it identifies only one contaminant color and potentially lets all others slip through, says Edward Sommer Jr., executive v.p. and technical director at National Recovery Technologies (NRT) Inc. in Nashville, Tenn. To remove this limitation, NRT has upgraded its MultiSort color-sorting technology to "see" the full visible color spectrum. The new MultiSort ES comes pre-programmed with a basic library of eight colors. An operator programs the system to search for one or several or all eight colors in a waste stream. MultiSort ES can sort 5000 lb/hr of material on a 1-meter-wide conveyor that operates at 8-10 ft/sec. A color video camera scans the entire width of the conveyor and transmits data to a controller, which can interpret 10-20 objects/second based on observing just 0.5 sq in. of bottle surface. An array of air jets receives a signal from the controller to divert a colored bottle from the clear stream.

A new automated near-infrared scanning system sorts bottles by polymer type at rates up to 8800 lb/hr. Developed by TiTech Autosort of Oslo, Norway, the system analyzes bottles traveling on a conveyor at up to 8.2 ft/sec. Good bottles drop off the end of the conveyor onto a second conveyor, while reject bottles are blown upwards by an air jet. The unit can detect up to 12 different polymers.

Recyclers who handle ground flake rather than whole bottles can now sort flake by polymer as it flows down a chute at rates up to 5000 lb/hr. The new Flake Sorter from NRT uses proprietary infrared sensing technology and high-speed spectral analysis to identify PVC, PET, HDPE, PP, PS, and acrylonitrile resins. It shows a 95-98% removal rate of contaminant flakes (using air valves), with a good-product loss of less than 0.5%. NRT sells the flake sorter in modules, each capable of sorting 1250 lb/hr. The first unit is operating in the U.S., NRT reports.

Spot undesirable additives

New models of polymer detection devices are doing more than just sensing the base resin. Materials containing flame retardants, heavy-metal additives, or fillers can be identified with a new hand-held instrument from AGR MbH of Essen, Germany. The new SlideSpec-S2 model can identify 22 different polymers, as well as the presence of certain additives, in 0.5 to 1 sec. A laser-like "spark" thermally vaporizes a small spot on the part surface. The material components in the spark plasma are atomized and activated to emit radiation. The atomic emission spectra are then analyzed to reveal common polymer types (including styrenics) and flame retardants containing halogens, phosphorus, magnesium hydroxide, or alumina trihydrate.

The unit also detects heavy metals in pigments or stabilizers (such as cadmium, lead, and zinc) and fillers such as calcium carbonate or talc. Detection is not inhibited by the presence of paint or surface contaminants.

The system has a spark pistol that contains the inspection head, which is attached by a 3-meter cord to the computer, whose screen displays the major and minor components of the sample. The unit fits in a portable carrying case and runs on a DOS platform using normal 220-v current.

Scrap parts containing flame retardants can be kept out of the recycling stream with new sensing capability in the P/ID 22 FT-NIR spectrometer from Bruker Optics, Billerica, Mass. The instrument was first developed for the automotive industry, but its new abilities extend its use to the electronics field. A simple upgrade to the materials library adds the flame-retardant identification capability. The device must touch the part and takes 3 sec to scan an object. The expandable library contains up to 36 materials.

Identification updates

The KID 1700 NIR identification unit from WMM-Sensorik of Pfinztal, Germany, has been improved with a larger material library, greater spectral range, and faster response. The unit uses a diode array spectrometer to analyze a part. Up to 10 of the 13 material models in the library can be selected at one time. The unit renders a reading in 1.5 sec when 10 materials are studied and takes about 100 millisec when one material from the library is selected.

The system also uses a wider spectral range (950-1700 nm) to gather more information on the polymer for improved identification accuracy. The sensing head, designed by Zeiss of Yenol, Germany, can measure moving granules to PE film 50 microns thick and does not require a smooth product surface.

WMM also showed a simpler plastics-identification device, the DAG-1, which recognizes only five resin types. It uses a light source, spectrometer, and PC to read 10-15 opaque or transparent pieces/second.

For a quite different approach to plastics identification, try rubbing parts with the Tribopen from Peter Walker Systems of Bergheim, Germany. The pen has a piston-type sensor head that generates an electrostatic charge when rubbed on the part. Each material generates a different charge. LEDs on the back end of the pen light to indicate the polymer.

The Tribopen can be designed to distinguish up to four materials using a multi-head pen. However, it cannot distinguish between closely related members of the same resin family, such as LDPE from HDPE. Special pens are offered to identify materials in cables, separate PET from celluloid films, or sort vehicle bumpers.

Peter Walker Systems also developed a new mobile infrared inspection system that can be taken from plant to plant. The new Portasort PolyAna 420 fits on a desk and is composed of an optical cell system with a spectrometer, PC, and software. A user-definable database of 40 different resins, blends, and fillers can be expanded using an IR-spectrum database of more than 2000 polymers.

Operation requires a 10-mm-diam. flat surface of a part to be placed against the spectrometer's viewing port.

Related Content

SD Polymers: 'One-Stop Solution for Mechanical Recycling'

‘Passionate’ recycler invests in people and technology to meet commitment to innovative, sustainable solutions for its processor customers.

Read MoreAvoid Four Common Traps In Granulation

Today, more than ever, granulation is an important step in the total production process. Our expert explains a few of the many common traps to avoid when thinking about granulators

Read MoreScaling Up Sustainable Solutions for Fiber Reinforced Composite Materials

Oak Ridge National Laboratory's Sustainable Manufacturing Technologies Group helps industrial partners tackle the sustainability challenges presented by fiber-reinforced composite materials.

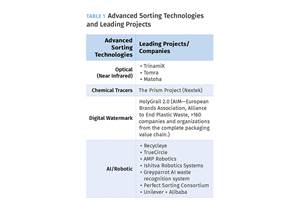

Read MoreRecycling: What's Ahead in Advanced Sorting Technology

As the industry tries to ramp up recycling, there are several innovative sorting solutions in the offing—ranging from enhanced optical sorting technologies and chemical tracers to advanced solutions based digital watermarks and artificial intelligence.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreRecycling Partners Collaborate to Eliminate Production Scrap Waste at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair will seek to recover and recycle 100% of the parts produced at the show.

Read More