EXTRUSION: What’s the Right Feed Throat Temperature?

Selecting the proper one is critical to the process.

In earlier columns I detailed the importance of the extruder feed throat design and how it affects both output and stability. Obviously nothing passes through the extruder that does not pass through the feed throat first, so its design is extremely important to the entire process.

So is feed throat temperature. It’s been noted that injection machine “extruders” often have higher specific output than extrusion extruders with the identical screw designs and discharge pressures. This is because injection molding machines do not utilize a separate feed throat. Instead, the barrel extends through the feed opening for strength reasons. As a result, the inner wall of the barrel at the resin entry point is usually much hotter than it is with an extruder having a separate feed throat.

The hotter inner surface on injection extruders increases the frictional drag between the barrel and polymer. There is a direct relationship between the barrel-to-polymer friction and output and often the output stability as well. Some extrusion extruders utilize the same concept. In those cases, specific output rates have been shown to improve 10-20%, depending on the polymer type, due to the greater and more rapid pressure development in the feed section.

In addition to improvements in output, a warmer feed throat can improve stability, particularly with polymers having low friction coefficients to metal and for high-temperature polymers. Surging occurs when the polymer adheres lightly to the barrel but then slips as the pressure in the feed area builds. This can result in an almost cyclic feed-rate variation that transfers all along the screw and results in a continuously varying output at the discharge.

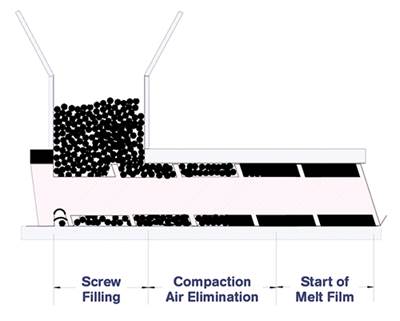

If warmer feed throats improve output and stability, why are they not more popular in extrusion? Primarily because many extrusion processors worry about the polymer melting prematurely in the feed opening. This is certainly a valid concern to anyone who has experienced that situation. However, it is relatively rare and can be controlled with a cooling jacket (see illustration). It seldom occurs when the screw is turning, but rather when it is stopped. The same is true of polymer melting and sticking to the early feed flights of the screw.

During processing the incoming polymer continuously absorbs heat from the screw and feed throat, which keeps the metal cool enough to prevent it from melting the resin too soon. But remember that a screw is a machined steel bar, and when one end is kept hot the other end eventually will get hot too if there is nothing to extract the heat. Interestingly, the screw does not actually touch the feed throat because of additional radial clearance in that area, so cooling the feed throat has only a minor convective cooling effect on the screw temperature. If the screw temperature needs to be controlled, it’s best to utilize internal cooling channels.

Essentially all extruders have some means to cool their feed throats; water is typically used. The feed throat is cored so that water can be passed through it to control the temperature. Some processors have attempted a more precise control mechanism by metering the flow or by controlling the outlet temperature, or both. Although this can produce a workable solution, it is not a true control because the feed throat changes temperature with various processes and polymer characteristics, and metering the flow and controlling the outlet temperature are only part of the overall thermal balance.

There is also a general misunderstanding about the feed throat by operators. Many consider it as only a hole through which to introduce polymer to the screw, when in fact it’s the initial part of the barrel. As a result they incorrectly assume that if a little water is good then a lot is better, and they wind up losing a control variable and often reducing the extruder performance. The same can be said for internal screw cooling.

Excessive cooling can significantly affect power efficiency, as the early part of the screw and barrel are where it’s desirable to maximize the energy going into the polymer rather than extracting energy. To get the proper energy balance in the feed throat, each extruder will have its own “best” temperature, as the balance is affected by other variables such as screw speed, zone 1 setting, polymer characteristics, mass of the extrudate, etc. This “best” temperature must be found through trial and error by comparing specific output and stability (head pressure) as the coolant flow is adjusted. By adding a separate thermocouple in the feed throat with a temperature indicator, the proper setting during changing conditions can be much more quickly achieved once the ideal temperature is determined.

Related Content

How to Set Barrel Zone Temps in Injection Molding

Start by picking a target melt temperature, and double-check data sheets for the resin supplier’s recommendations. Now for the rest...

Read MoreThe Importance of Melt & Mold Temperature

Molders should realize how significantly process conditions can influence the final properties of the part.

Read MoreHow to Stop Flash

Flashing of a part can occur for several reasons—from variations in the process or material to tooling trouble.

Read MorePBT and PET Polyester: The Difference Crystallinity Makes

To properly understand the differences in performance between PET and PBT we need to compare apples to apples—the semi-crystalline forms of each polymer.

Read MoreRead Next

Don’t Overlook the Feed Section

Most extrusion screw designers often do not design the feed section with the same rigor as other sections. This is odd since nothing goes through the screw that doesn’t first go through the feed section.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More.jpg;width=70;height=70;mode=crop)