Why & How to Assemble Parts While They’re Still Warm

For any molder seeking to maximize productivity and efficiency, carefully managing inventory and warehouse space is a key concern. One way to address this challenge is to assemble parts directly out of the mold, when they’re still warm.

For any molder seeking to maximize productivity and efficiency, carefully managing inventory and warehouse space is a key concern. Processors must constantly seek ways to keep parts out of the work-in-progress (WIP) stage and flowing through the line. One way to address this challenge is to assemble parts directly out of the mold, when they’re still warm.

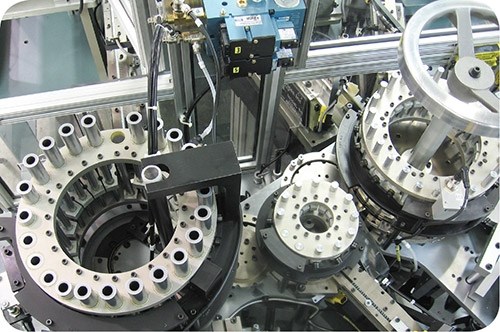

Assembling parts straight from the mold reduces the floorspace and labor required for handling the part, and it keeps parts moving through the operation. Better yet, it can help improve productivity and increase the bottom line. Let’s take a closer look at whether warm-parts assembly can work for your operation and at the challenges involved and how to overcome them.

First, a caveat: Assembling warm parts isn’t always necessary or recommended. Consider a processor that molds a part in only three colors initially. Maintaining inventory and keeping the parts moving through assembly would be relatively manageable. However, if that same molder later finds itself making parts in 20 different colors, inventory becomes much more of a challenge, and the prospect of assembling the parts warm becomes more attractive.

Similarly, molders that deal with parts in multiple cavities and/or having thin walls could benefit from the practice, as placing these parts in a box for inventory while they are still warm may cause them to become misshapen, leading to problems during later assembly.

OVERCOMING THE CHALLENGES

Not surprisingly, handling and assembling warm parts creates its own set of challenges that must be addressed to prevent damage and to avoid a system shutdown. These factors include:

•Creating a buffer system that allows for shutdown or adjustment of the automation system without affecting the mold’s ability to continue producing parts.

•Optimizing timing between the mold and the automation machine.

•Minimizing friction to allow for proper part orientation and handling.

•Adjusting the snapping forces needed for part assembly.

•Ensuring versatility in automation equipment to work on both warm and cold parts.

When assembling parts straight from the mold, companies typically position the assembly equipment next to the molding machine. Because of this proximity, many feel that moving the parts from the mold directly to the assembly machine is the most efficient course of action.

Unfortunately, should a misfeed occur (either with the assembly equipment or because of a defect in the molded part) it can have a “domino effect” that results in a stoppage of the mold. And, of course, no molding means no money.

A better and less risky option is to build a buffer into the operation, ideally with 20 to 30 minutes’ capacity. In case of a disruption, the part would be moved from the mold to a temporary bulk storage area or small buffer bin at the press and then put back into the assembly system in a “first-in/first-out” manner. Holding parts in a buffer bin not only gives personnel the time to remedy the problem, but it also eliminates the time necessary for boxing up parts and moving them to a warehouse for storage. Further, it prevents the parts from fully curing and becoming brittle, which can cause problems in later assembly.

Contrary to what many may think, use of a buffer won’t slow down the assembly operation. Because the speed of the automation equipment is going to be faster than the molding speed, it will easily catch up with any backlog of parts in the buffer bin. Also keep in mind that this buffer will only be used when a bad part or pause in assembly occurs; otherwise, parts will go straight from press to assembly without using the buffer.

One challenge to be aware of when building a buffer is that the parts need to be reoriented for assembly after they have been placed in the bin. Even so, the cost of using a vibratory feeder bowl or rotary feed bowl for this task is typically less expensive and less time-consuming than a stoppage in the mold and/or assembly system.

DEALING WITH FRICTION, OTHER FACTORS

Without proper consideration, friction can cause defects, or even machine shutdown, when assembling parts straight from the mold. For that reason, molders should ensure that their equipment supplier accounts for friction, as this will affect the way in which they use frictional devices to spin or orient still-warm parts.

One way to account for friction is to evaluate the part design to determine its robustness, starting by using a cold part. If the concept is marginal with cold, room-temperature parts, then it will most likely fail during a warm-part assembly. One of the best solutions, however, is to design an assembly system that doesn’t rely on friction-based alignment or movement in the first place.

Similarly, molders need to ensure that their machine builders account for required assembly forces. Warmer parts go together more easily than colder ones. That is a great benefit because the machine exerts less force on the part, reducing the risk of part damage.

Yet a molder may encounter a situation where the same system needs to assemble cold parts. For example, if another machine is undergoing routine maintenance, the molding machine will eventually create a backup of parts that are cold by the time the assembly system is ready to run again. The solution is to specify a machine for assembling warm parts, but which can also easily assemble cold parts.

BUILDING THE MACHINE

Building an assembly machine that is adaptable and can work with freshly molded parts is a challenge in itself. The best approach is to work closely with an automation equipment supplier during the design phase, as the vendor can help replicate the process of assembling the part straight from the mold to make sure that it will work properly in the customer’s real-life scenario.

Also, molders must remember that this approach isn’t an out-of-the-box solution, and areas of the assembly operation they are unsure of should be developed in a flexible way. Doing so allows for simple tweaking on-site rather than significant rebuilding or configuring of the assembly system and changing the overall parts flow.

Realistically, it may take a little bit of time to optimize the system, yet that time will be well spent given the potential production advantage it can provide to molders and assemblers alike.

Related Content

Reengineered Series of Laser Welders

Dukane’s Laser Plastic Welding Line covers full spectrum of needs from stand-alone to fully-integrated systems.

Read MoreEco-Sustainable Pad Printing Ink

Incups GN Series passes the ISO cytoxicity test and complies with EuPIA.

Read MoreX-Ray Vision Inside Parts Gets More Affordable for Processors

Shimadzu’s new benchtop x-ray CT scanner provides internal and external metrology and flaw detection at a fraction of the previous cost.

Read MoreNew Cleanroom-Rated Static Eliminator

Neutralize static hands-free in sensitive medical, pharmaceutical and electronic manufacturing operations.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More

(2).jpg;maxWidth=300;quality=90)