Sussex IM CEO Keith Everson (right) and Kyle Kopp, v.p. of manufacturing, in front of the trimming and leak-testing station of the automated injection and blow molding cell that produces sports water bottles with IML.

Sussex IM is an injection molder and contract manufacturer with broad competence in secondary operations—degating, barcoding, pad printing, digital ink transfer, in-mold labeling and decorating (IML, IMD), digital watermarking, laser etching, sonic and vibratory welding, functional testing, and even retail packaging. To make all that efficient, the company is also committed to automation. As it states on its website (sussexim.com), this combined focus is integral to the company’s philosophy:

“Value-added operations are one of the criteria for distinguishing between shoot-and-ship molding—where a part is ejected from the mold and essentially goes straight into a box—and engineered molding. One of the most efficient procedures in plastics manufacturing involves integrating downstream operation to the molding cycle. While we have control of the part, through robotics and fixturing, we can effectively reorient, inspect, test, decorate, machine, assemble, and package.”

So, when Sussex needed to make a hollow-bodied object with solid attachments of a different material, it adopted blow molding as just another secondary operation to injection molding, and engineered the automation to link them together efficiently.

Bringing an innovative technique over from Asia and adding automation in place of hand labor.

The concept of joining two materials in the mold—in-mold assembly—was already familiar to Sussex IM, which has experience with a wide variety of multi-shot injection molding techniques. Extrusion blow molding, however, is very different from injection molding, a likely reason why there aren’t a lot of shops that do both. Fortunately, Sussex IM had a history in blow molding—and some long-time employees who remembered that experience.

Automation & Control

Sussex IM was started in 1977 as Sussex Plastics Inc. The current CEO, Keith Everson, has been with the firm almost all of that time, during which, Sussex has grown to a $70 million operation that employs 500 people and houses 70 injection machines from 25 to 955 tons—plus two blow molders—at two facilities in Sussex, Wis., that total 210,000 ft2. Its activities are divided almost equally among four market sectors: consumer goods (including cosmetics packaging), healthcare, agriculture, and industrial. Sussex also has a small proprietary Sussex Brands division, which makes Mr. Lid food-storage containers (mrlid.com).

“Back in the late 1980s,” recalls Everson, “we reached a fork in the road: go automated or do just manual jobs. We chose automation and to do it internally. We hired a full staff of seven automation engineers and technicians to build custom automation for specific programs. Post-mold operations are a big niche for us, so we build several million dollars worth of automation each year. If we had to buy that outside, it would cost twice as much, take twice as long, and work half as well.”

Adds Kyle Kopp, v.p. of manufacturing, “In-house automation expertise gives us total control. We build systems for our people and our style of operations, so our people find it more intuitive and learn it quicker. Doing automation in-house also makes it easier to optimize and fine-tune. This gives speed to market by allowing us to react faster.”

Compact integrated cells save “huge” amounts of energy by not moving parts around the plant.

Sussex IM has 100 robots and several collaborative robots (cobots), the latter used to transfer products between operations. The firm also has a 3D printer that allows it make custom plastic components for jigs, fixtures, mandrels and robot grippers, as well as prototype parts.

Kopp notes that Sussex automation engineers pride themselves on designing compact workcells that perform multiple operations within a small footprint: “By streamlining the assembly process, we can eliminate unnecessary touchpoints, minimize excess handling of WIP items, and actually yield significant energy savings. These are discrete pieces of the sustainability puzzle that may be overlooked in conventional thinking.”

Paired Processes

An example of such compact cells are the two lines making reusable water bottles (“sports bottles”) in a variety of sizes and color configurations, using paired injection and blow molding machines. According to Everson, these bottles formerly were made only in Asia. The original procedure was to injection mold TPE soft grips, which were hand loaded into fixtures, from which a robot would place them in the blow mold. After molding, the bottles were trimmed and pad printed.

When Sussex IM took on this application, it had the advantage of prior experience with extrusion blow molding. “About 25 years ago, we had five machines making seasonal point-of-sale decorations—pumpkin heads, Christmas trees, candy canes,” Everson notes. “Then we got out of it. Most of that business went to Asia.”

“The trick with extrusion blow molding is getting repeatability. You have parisons out there blowing in the wind.”

When Sussex IM approached blow molding again, five years ago, it decided to focus only on specialty niche applications. For the sports bottles, Sussex approached it in its accustomed fashion—with a do-it-ourselves attitude and an urge to automate.

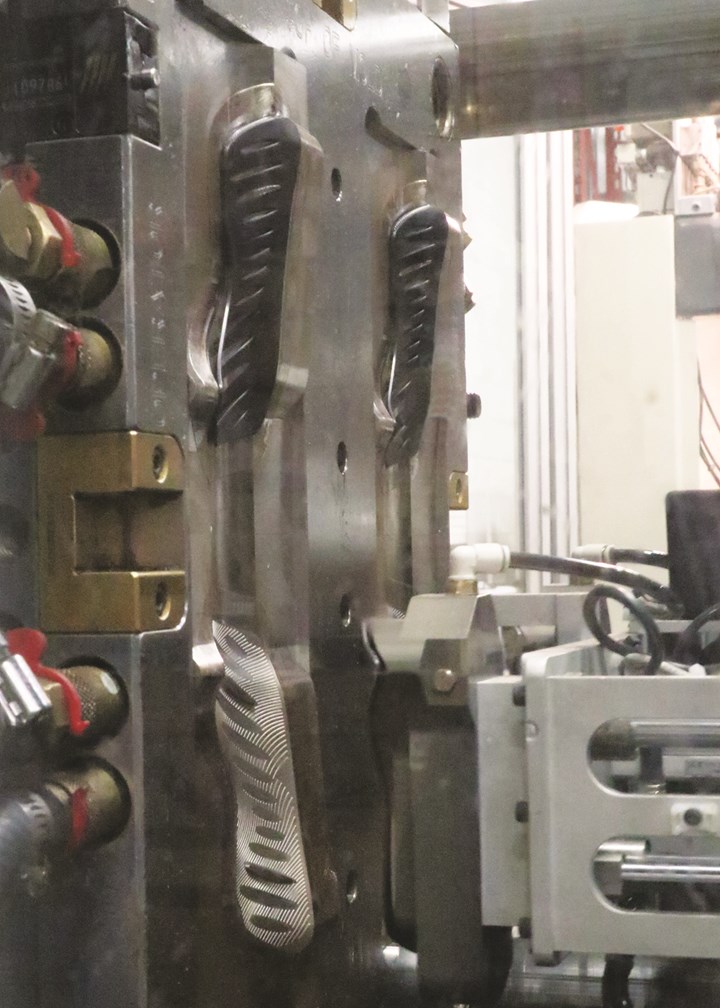

The result was a cell in which the process starts with injection molding four TPE soft grips in a 120-ton press. A six-axis robot extracts the grips with end-of-arm tooling that also picks up two in-mold labels and places all of them in two aluminum blow molds—one grip in each mold half—in an adjoining press.

Sports bottle cell

Four TPE soft grips are removed from the injection mold of a 120-ton press by a six-axis robot.

The robot places the TPE grips on both sides of two blow molds.

The same six-axis robot and EOAT that transfers the TPE grips from injection to blow molds also picks and places in-mold labels in the blow molds.

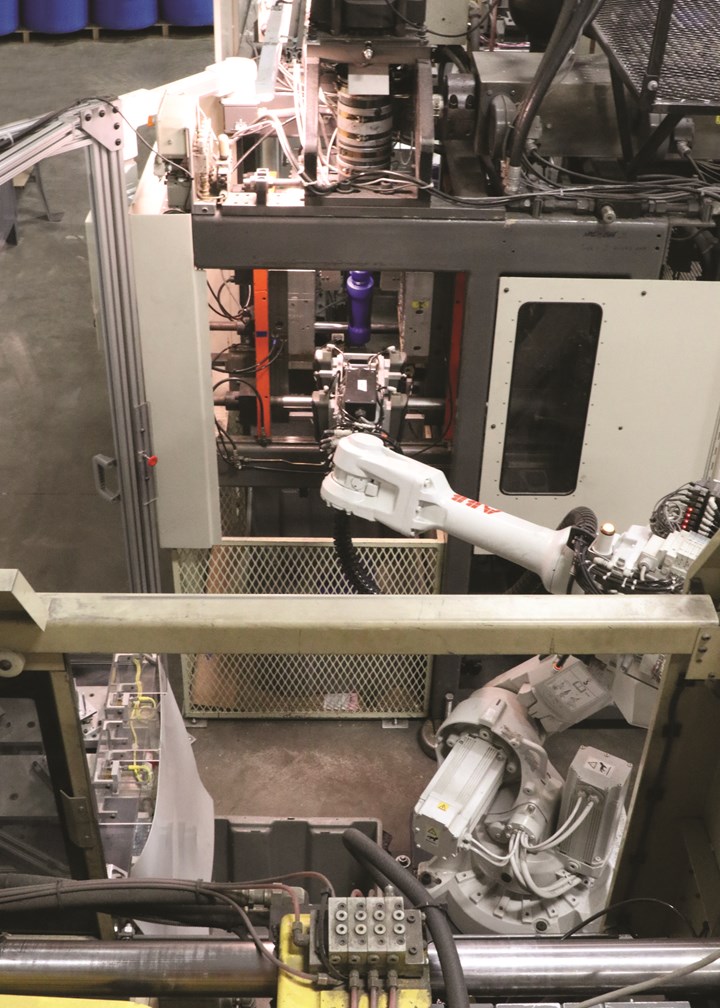

The six-axis robot waits by the blow mold for a second robot to remove the bottles for leak testing and trimming. This view is looking over the injection press, whose tiebar is seen at bottom.

The blow molder is not a brand-name machine but a custom system built to Sussex’s unique specifications at a local machine builder with a global reputation. It has two accumulator heads—one for each cavity—and an 80-ton clamp.

After blow molding, the TPE grips are bonded to the bottle body (LDPE or PP) and in-mold decorated (eliminating the subsequent pad-print operation). A secondary robot removes the two bottles and transfers them to another station, where the bottles are automatically trimmed, leak tested and passed to a wairint conveyor system. Lastly, an operator gives a quick visual check, adds a unique multishot cap assembly, product information tag, and UPC code label, and packs the bottles for retail distribution. This is all done within the blow molding cycle.

Finished bottles in trimming station.

The two sports-bottle cells currently run 24/5, but Everson sees other applications beckoning for this dual-molding approach and its nearly full-wrap IML capability. One factor is the growing popularity of refillable water bottles versus single-use PET bottles. Another is the untapped potential in products such as wipes containers and medical products (Sussex is ISO 13485 certified).

An operator touches the finished bottles only for a quick visual check, adding a cap and UPC label, and packing.

Other injection molders might be attracted to the idea of blowing hollow-bodied objects with grips, handles, or other attachments incorporated via an insert-molding approach. But a word of caution is in order. Notes Kopp, “There are aspects of the process that can be challenging when you combine multiple technologies. Making it all function within cycle time consistently is not easy. It’s challenging, but we work very hard to eliminate variables.”

Related Content

Know Your Options in Injection Machine Nozzles

Improvements in nozzle design in recent years overcome some of the limitations of previous filter, mixing, and shut-off nozzles.

Read MoreHow to Set Barrel Zone Temps in Injection Molding

Start by picking a target melt temperature, and double-check data sheets for the resin supplier’s recommendations. Now for the rest...

Read MoreImprove The Cooling Performance Of Your Molds

Need to figure out your mold-cooling energy requirements for the various polymers you run? What about sizing cooling circuits so they provide adequate cooling capacity? Learn the tricks of the trade here.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More