Unlikely Pairing: Environmental Activist and Multinational Packaging Manufacturer See Eye to Eye on Global Plastic Waste Crisis

Both want plastics out of the natural environment. They agree that human behavior is the problem. One global firm is altering its own behavior to promote four types of recycling.

You might not expect shared passion and convictions on the global plastic waste issue between the founder of an organization devoted to eliminating single-use plastics pollution and the CEO of the world’s largest maker of PET packaging films. But that’s what was on display at an unusual shared presentation in New York City last week by Lizzie Carr, founder of Plastic Patrol, and Anantshree Chaturvedi, vice chairman and CEO of FlexFilms International.

Lizzie Carr’s Story

Ms. Carr is devoted to paddle boarding, which led to her investigations of plastic and other waste she encountered in her journeys, which have included a 400-mile, 22-day voyage along England’s waterways in 2016; a 7-hr crossing of the English Channel in 2017; and 170-mile trip down the Hudson River from Albany to New York city in 2018. Along the way, she took thousands of photos of the plastic waste she encountered.

In 2016, Carr founded a nonprofit volunteer organization called Plastic Patrol, with an app by which volunteers can communicate. Volunteers in 68 countries have conducted more than 130 clean-ups and have collected more than 300 tons of rubbish (more than 197,000 individual pieces) from rivers and other natural environments. Carr calls this “citizen science”—crowd sourcing data that can be used by scientists to analyze global problems. Plastic Patrol is working with the University of Nottingham, England, to catalog the locations, types, and even brands of plastic waste found and logged on the app by the volunteers.

I attended this event largely out of curiosity to find out whether Plastic Patrol would challenge the conventional wisdom that “ocean plastics” are largely an Asian and African problem, not an issue for the developed economies of the Western world. I don’t think that Ms. Carr’s group has changed my mind on this issue, but that’s not to say there isn’t plenty of trash that gets into our own waterways. I asked Ms. Carr what were the main types of plastics waste she found in her paddle board adventures, and she said the top three were plastic bottles, bags, and packaging films.

Speaking after Carr, FlexFilms’ Chaturvedi expressed views remarkably in sync with Carr’s. His firm is based in India, but has BOPET, BOPP, and multilayer film plants in India, Dubai, Mexico, Poland, Egypt, and the U.S. (in Elizabethtown, Ky.). FlexFilms is a unit of Uflex Ltd., India’s largest flexible packaging company. “We want plastics to have a future,” Chaturvedi said. “We don’t want plastics where plastics are not supposed to be.”

The two speakers agreed that eliminating plastics waste from the environment is not primarily a technical problem but a human behavior problem. “It’s not plastic destroying the environment, it’s us!” stated Chaturvedi. While Carr’s view of the human behavior problem leans toward weaning people away from single-use plastics, like water bottles, Chaturvedi is focused more on the need for comprehensive recycling for a true “circular economy.” “There’s so much value that goes into making that stuff,” he said, that we can’t afford to just throw it away and bury it in landfills.”

Project PlasticFix

That’s what led the parent company Uflex to launch Project PlasticFix. It involves four main thrusts:

• Recycling of multilayer, multimaterial films with the aid of a compatibilizer into injection and blow molded products like garbage cans, highway dividers, and outdoor furniture. In 1995, the Davos Recycle Forum granted an award to Uflex for recycling printed, laminated film of metalized PET/LDPE/BOPP. In India, FlexFilms utilizes its own recycled films in the form of injection molded core plugs for its film rolls.

• Recycling post-consumer recycled (PCR) monolayer films into new films. FlexFilms has been doing this for 18 months in India and is now offering 90% PCR PET film and will soon launch a 100% PCR product.

• Using pyrolysis to convert plastics not easily recyclable by other means into fuel oil.

• Formulating plastic films to biodegrade into biomass, not “microplastic” particles. Uflex developed a patented “biodegradable enzyme,” called Pepzyme that reportedly allows for 100% degradation by natural soil bacteria. Use life of products can be tuned to months or years before degradation begins. According to Chaturvedi, this is the only commercial technology that allows plastic products to be both fully recyclable and fully biodegradable.

Chaturvedi says Uflex uses all four of these technologies in India, but plans to introduce them selectively at its facilities in Poland, Mexico, England and U.S. For example, its Mexican BOPET film plant will install an Erema machine to reclaim PCR in the first quarter of 2020. And, Uflex is willing to license these technologies to others.

My Two Cents

This entry is already rather long, but if you care to know what I think about all this, here goes:

1. Given that the majority of the plastic waste problem, from a global perspective, comes from less developed countries, a lot can be accomplished through so-called “micro capitalist” ventures to collect waste plastics at the source—before they get into waterways. Enlist thousands, or tens of thousands of people in those countries to become self-employed collectors of plastic waste and earn a living delivering that waste to depots that can serve local industrial recycling firms. This has already been practiced on a small scale in places like the Caribbean.

2. Collecting and sorting are the two major technical and economic hurdles to larger-scale recycling efforts. A shortcut around both obstacles is chemical recycling—turning dirty, mixed plastics back into industrial chemicals or diesel-type fuel. I see a constant stream of announcements by startups and established companies that are itching to field new technologies for chemical recycling of plastics. Scratch that itch and everybody wins.

Related Content

Young Stretch-Film Processor Bets on Nanolayers

Going up against companies with as much as double its capacity, young stretch-film processor Zummit believes that new technology — notably 59-nanolayer films — will give it a competitive edge.

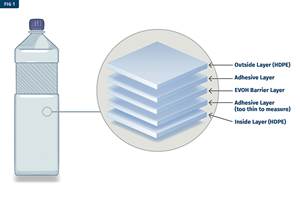

Read MoreMeasuring Multilayer Plastic Containers Made Easier With Today's Ultrasonic Gauges

Ultrasonic gauge technology has evolved to simplify measurement of very thin layers in plastic containers. Today’s gauges with high-frequency capabilities and specialized software can make multilayer container measurement quick and easy for ordinary users.

Read MoreSolve Four Common Problems in PET Stretch-Blow Molding

Here’s a quick guide to fixing four nettlesome problems in processing PET bottles.

Read MoreHow to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

Read MoreRead Next

Trash as Value: Turning Ocean Waste Into Viable Products

So-called “ocean plastics” is a global problem, but a wide range of companies across the entire supply chain have put in the time, money and R&D efforts necessary to make capturing and converting the material into a sustainable business. But demand must follow.

Read MoreEarth Day 2019: Reinventing Reuse with Ocean-Bound Plastics Initiatives

A look at new products and initiatives to help curb ocean-bound plastics, including HP, adidas and Dow.

Read MoreG7 Summit: Leaders Agree to Ocean Plastics Charter

Five countries of the G7 group—excluding the U.S. and Japan—endorsed a plastics charter on ocean pollution.

Read More