AMP Robotics Extends Partnership with Food-Grade rPET Manufacturer Evergreen

Evergreen now has 15 of AMP’s robotic sorting systems guided by AI.

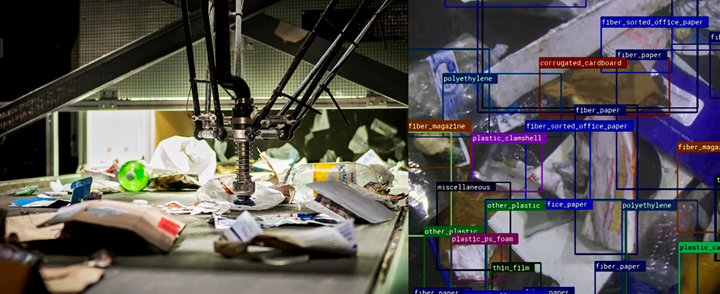

Pioneer in AI, robotics, and infrastructure for the waste and recycling industry AMP Robotics has extended its partnership with Evergreen, one of North America’s three largest producers of food-grade rPET. Evergreen, which has grown through acquisitions to four locations across North America from its original facility in Clyde, Ohio, now has 15 of AMP’s robotic sorting systems guided by artificial intelligence installed or planned across three facilities. In addition to six robots in Clyde, Evergreen has added six in Riverside, Calif., and will soon add three in Albany, N.Y.

AMP’s technology identifies and sorts green and clear PET from post-consumer bales of plastic soft drink bottles at speeds up to three times faster and at a higher accuracy than manual sorters can achieve. Evergreen then recycles the material into reusable flakes or pellets, which it sells to end markets as feedstock for new containers and packaging.

Evergreen claims that with AMP’s robots focused on refining the quality of material, separating plastics more precisely by color, it has seen a notable improvement in purity along with pick rates of up to 120 bottles/min.—an increase of up to 200%. The robots are removing up to 90% of contamination, on average, across different lines at Evergreen’s Clyde facility.

Thanks to its expansion and infrastructure investments, Evergreen’s annual capacity of rPET has swelled to more than 147 million/lbs, up from 40 million/lbs a year ago. Evergreen has also increased the number of PCR-PET bottles it collects and recycles, from two billion PET bottles annually to 11.6 billion bottles.

In addition to PET, AMP’s AI platform precisely identifies and captures plastics including HDPE, LDPE, PP, and PS, sorted further by color, clarity, and opacity, along with different form factors—lids, tubs, clamshells, cups, and more. AMP’s technology also recovers cardboard, paper, cans, cartons, and many other containers and packaging types reclaimed for raw material processing. It can quickly adapt to container packaging introduced into the recycling stream with recognition capabilities to the brand level—increasingly critical as demand for sufficient quantities of high-quality recycled material grows to meet consumer packaged goods companies’ commitment to use of post-consumer recycled content.

Related Content

-

How to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.

-

Prices of All Five Commodity Resins Drop

Factors include slowed demand, more than ample supplier inventories, and lower feedstock costs.

-

The Strain Rate Effect

The rate of loading for a plastic material is a key component of how we perceive its performance.