Domo, RPD Partner to Accelerate 3D Printing with Advanced Materials

This collaboration combines the development of Sinterline Technyl PA6 powders with expertise in SLS process technology.

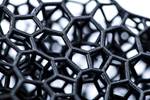

Domo’s Sinterline PA6 powders combined with RPD’s SLS printer.

Domo Chemicals has teamed up with Rapid Product Development GmbH, an Austrian provider in 3D printing, to provide advanced materials for the market.

The increased use of Selective Laser Sintering (SLS) in high-performance functional parts in automotive and other demanding market segments, has created a need for plastic materials that are capable of bridging the gap between conventional injection molding and 3D printing. Domo’s partnership with RPD is targeted at accelerating this production process, by offering a growing range of dedicated Sinterline PA6 SLS powders that are complemented by a complete package of support services.

The collaboration will benefit from RPD’s advanced know-how in application development and SLS process technology. Another advantage comes from the integrated component design capabilities of HUB by Sinterline, Domo’s unique set of SLS services from material selection to stringent physical part testing.

“As our Sinterline Technyl PA6 powders continue to set new standards in functional 3D printed applications, we are delighted to join forces with RPD,” says Dominique Giannotta, Sinterline program leader at Domo Chemicals. “This partnership opens up new opportunities for SLS customers in near to small series automotive and other higher-volume application areas beyond prototyping.”

“Together, we will help designers and manufacturers maximize the benefits of our combined material and process expertise for enhanced product differentiation, faster time-to-market, and greater development cost efficiency in this game changing business,” Giannotta said.

Domo’s Sinterline product family is available in various unfilled and glass-filled grades. Just recently, a specialized PA6 based powder was added to the range to meet the requirements of functional wear-and-friction components.

“Sinterline has pioneered the use of high-performance PA6 in 3D printing, and allows us to leverage the same polymer base that has proven so successful in many existing injection molding applications,” said Wolfgang Kraschitzer, general manager and plastics processing leader at RPD. “Backed by the joint application development services of our companies, even highly stressed automotive components can now be successfully 3D printed in PA6 to near-series and fully functional quality standards.”

Related Content

-

420 Stainless Steel Now Qualified With TrueShape 3D Printing Technology

NPE2024: Mantle's additive manufacturing technology is designed for precision tooling.

-

Make Every Shot Count: Mold Simulation Maximizes Functional Parts From Printed Tooling

If a printed tool only has a finite number of shots in it, why waste any of them on process development?

-

Production Tool, Prototype Time

Mantle's metal 3D printing technology targeted toolmaking and injection molders and moldmakers are taking notice.

.png;maxWidth=300;quality=90)