Assembly:High-Precision and Versatile Dual-Axis Servo Spin Welder

Forward Technology’s new HD2X-OSW welder is well suited for use in a broad range of molding applications; company upgrades its industry-leading linear vibration welder.

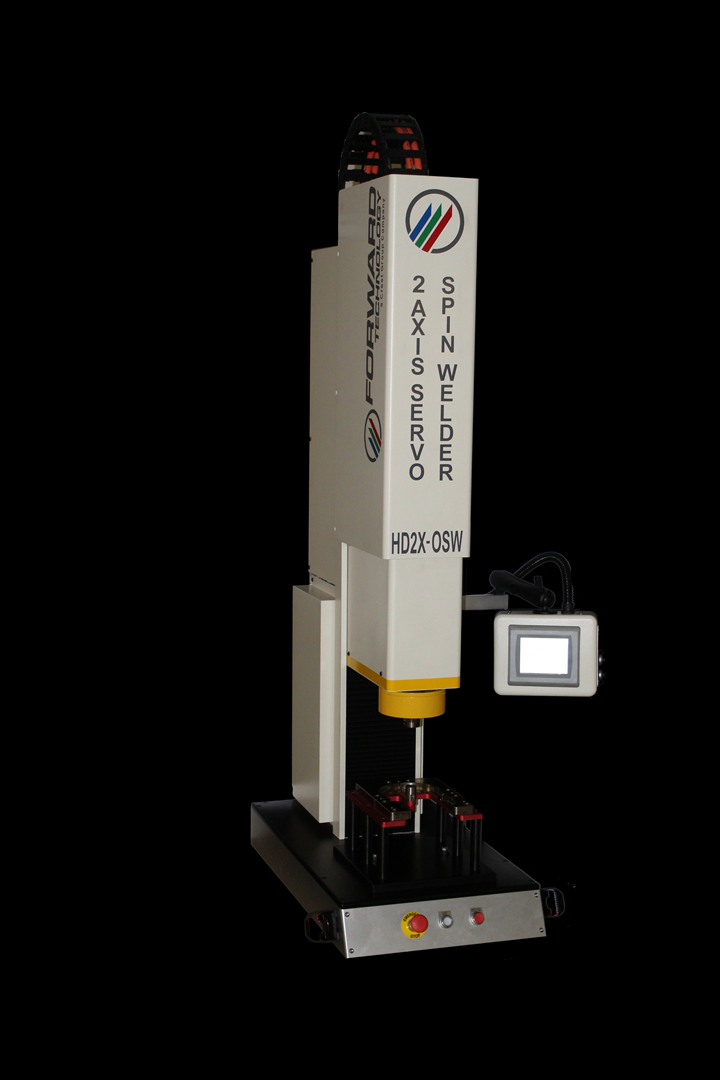

A dual-axis servo spin welder designed for a wide range of injection molded applications that require high rotational power and the highest degree of vertical and rotational precision, is newly available from Forward Technology, Cokato, Minn. . The company has also enhanced its industry-leading linear vibration welder for a range of large injection molded parts.

▪ The HD2X-OSW servo spin welder reportedly provides excellent rotational and vertical positioning, along with a 24-in of stroke (weld height range). This large range allows for simple push-button recipe changes when switching from tall to short tools, or vice versa, without manually adjusting the head’s vertical position. The spin welder orients part halves relative to each other with rotational tolerance accuracy of ± 0.1-deg. and provides a finished vertical weld tolerance of ±0.002-in.

The 600 lbs of press force is said to give process engineers plenty of head room when designing spin weld applications, including those with difficult-to-weld materials and large diameters. Said general manager Brett Raisanen, “The new HD2X-OSW spin welder combines precision and versatility, thus making it suitable for large and small applications alike.” The unit comes with an upgraded Allen-Bradley package which allows for robust controls and a range of opportunities for customization and automation, along with Statistical Process Control (SPC) options and other networking advantages.

When compared to other orienting or non-orienting models, the dual-servo system is said to allow for precise control of welding depth (collapse or absolute distance with an accuracy of ±0.002-in) and to enable synchronization of vertical and rotational movement to optimize the weld process. The full servo control also allows for setting a recipe adjustable load position, reducing the stroke during each cycle and saving valuable cycle time.

▪ The company’s DLVW-4848-LX vibration welder has been upgrades with an enhanced drive for additional analytical options. The unit uses synchronized heads to provide substantial amounts of weld force and is capable of welding parts up to 48-in by 48-in or multiple smaller parts. The patented two-pole digital (servo) drive technology is said to allow for vastly improved process control while substantially increasing the available power.

The DLVW-4848-LX is particularly suited for welding of large automotive parts such as intake manifolds, instrument panels, and engine covers, along with plastic pallets for the transportation and logistics industries. In the fast-growing plastic pallet industry, the vibration welder is an effective alternative to hot plate systems, offering significant cycle time reductions. As a standard benefit with all Forward Technology equipment, these large welders can easily be integrated into automated systems for further labor reduction and increased throughput.

Forward Technology offers the DLVW-4848-LX in its laboratory for quick turnaround welding services for customers who are undertaking prototyping and concept testing. The company utilizes its inventory of existing prototype tooling to reduce both cost and lead times for prototype applications.

Related Content

-

Medical Molder, Moldmaker Embraces Continuous Improvement

True to the adjective in its name, Dynamic Group has been characterized by constant change, activity and progress over its nearly five decades as a medical molder and moldmaker.

-

How to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

-

Automotive Awards Highlight ‘Firsts,’ Emerging Technologies

Annual SPE event recognizes sustainability as a major theme.

(2).jpg;maxWidth=300;quality=90)