Automotive LED Optic Parts Run on LSR Plug-n-Play Conversion Kit

Zeiger uses Dowsil liquid silicone rubber and a Milacron-FANUC Roboshot to mold high-performance LED automotive parts.

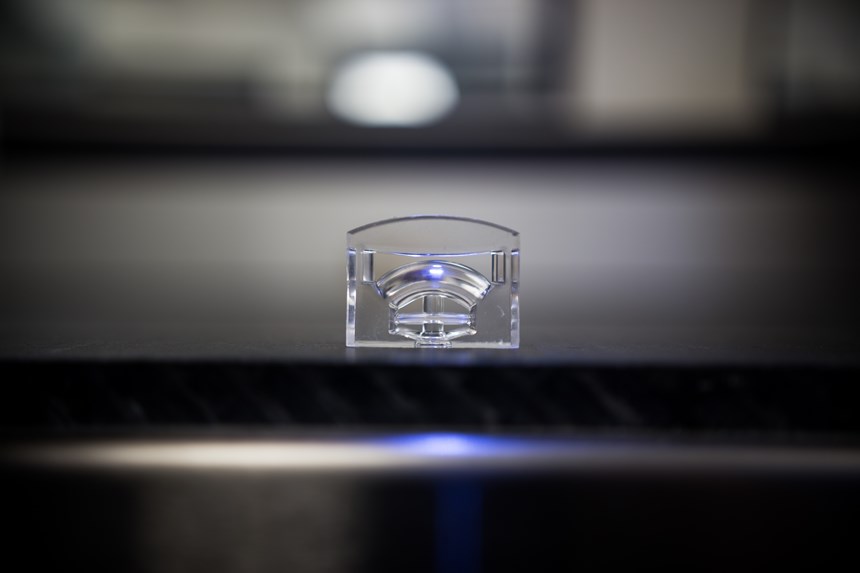

Zeiger Industries is molding a high-performance automotive LED optical part made from Dowsil MS-4007 liquid silicone rubber (LSR) on a Milacron–FANUC Roboshot a-S55iA with that company’s new iHMI Controller. The Roboshot is running a two-cavity mold mounted to a M.R. Mold universal base with a single-drop-gated cold runner system.

The production cell will feature an Elmet TOP 5000P dosing system, a Yushin YC-100 robot and a Thermal Care air-cooled EQ3A01 portable chiller. The Zeiger LSR Plug-n-Play kit incorporates a Wexco777 water-cooled barrel, Zpringlok LSR pre-closed valve, ZSAR PM zero compression ratio screw and Zeiger’s proprietary barrel/screw sealing device. The Dowsil MS-4007 material, like the rest of the Dowsil Moldable Optical Silicone portfolio, reportedly exhibits excellent performance in demanding conditions and enables complex optical designs that cannot be replicated with more rigid materials.

In this application, Zeiger reports that the resulting lens will allow 15% more light transmittance than a typical PC lens.

Related Content

-

Minnesota Rubber and Plastics Opens Innovation Center

The plastics and rubber compounder and molder has opened the 9000-ft2 center that’s intended to help speed product development with design, prototyping, testing and production capabilities.

-

Datwyler Expands O-Ring Production

The company has added injection molding machines to production sites in Mexico and China to boost production.

-

Silicone Elastomer Course Returns

After completely filling the classroom last year, the Silicone Elastomers Technology and Fabrication course returns to Pomona, Calif. Jan. 31-Feb. 3.