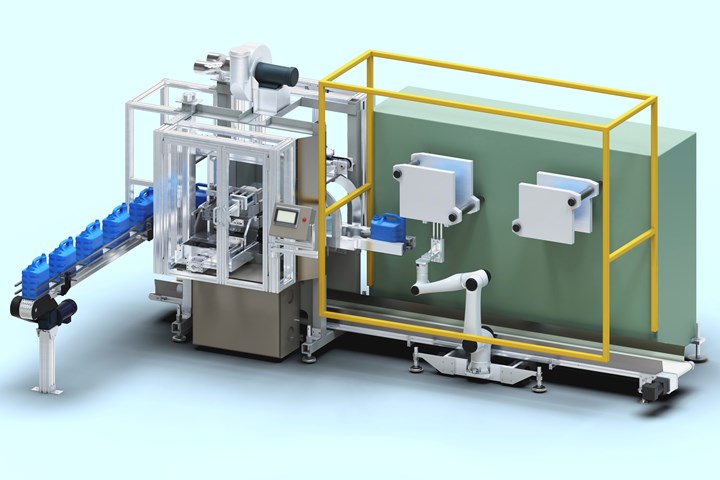

Cobot Takeout System for Shuttle Machines

NPE2024: Proco Machinery upgrades its Robopik bottle takeout system for shuttle blow molders with the addition of a collaborative robot.

Updated Robopik bottle takeout system from Proco Machinery substitutes a versatile cobot for older fixed automation. Source: Proco Machinery

The next generation of Proco Machinery’s Robopik bottle takeout system is distinguished by its use of a jointed-arm collaborative robot (cobot), said to offer greater flexibility and adaptability than older fixed automation. The Robopik, designed for unloading and deflashing containers from shuttle blow molders, can be reconfigured easily to handle different types of products and adapt to changing production requirements, Proco says. The magnetically coupled cobot is said to also unload products faster and with greater accuracy than previous systems. The new system can handle delicate or irregularly shaped containers and minimize the risk of damage or defects.

It also features built-in safety features such as collision detection, emergency stop mechanism and protective barriers. Advanced connectivity enables seamless integration with other “smart factory” (Industry 4.0) technologies.

Related Content

-

All-Motor Driven Pad Printing Machine

Deco Technology now selling the new ML-500E linear & servo motor driven from microPrint of Switzerland

-

Diverse 24V Line-Up of Static Ionizing Bars

Simco’s IQ Easy portfolio includes three 24V static neutralizing bars designed with M12 connectors that allow for power to the pins and more.

-

New Cleanroom-Rated Static Eliminator

Neutralize static hands-free in sensitive medical, pharmaceutical and electronic manufacturing operations.