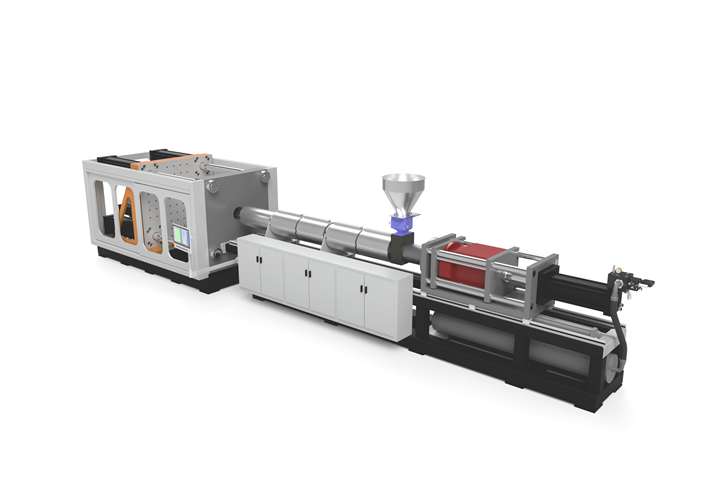

Medium-Pressure Machine for Structural Foam

Wilmington’s 500-ton model is suited to both solid molding and thin-wall structural foam.

Wilmington Machinery has launched the Lumina MP500 medium-pressure injection machine, a 500-ton version of the MP800 introduced several years ago (Feb. ’17, Keeping Up). Though capable of solid molding, the MP500 is aimed primarily at structural foam parts for automotive, recreational, material-handling and enclosure parts. Compared with Wilmington’s low-pressure foam presses, the MP500 has twice the injection pressure and clamping force, suitable for molding thin-wall or core-back foamed parts. But in common with the firm’s low-pressure machines, the MP500 has a 30:1 L/D plasticating unit capable of compounding additives and processing 100% recycled materials, as well as being ported for direct gas injection.

Like the MP800, the new, smaller model has a reciprocating screw as standard with two-stage (screw/plunger) injection optional. The reciprocating-screw version comes with a reportedly unique inline accumulator that offers double the shot volume typical for a given screw diameter while retaining first-in/first-out performance. Shot size for foam is 40 in.3 (approx. 15 lb of HDPE); for solid molding it’s 240 in.3 (approx. 7.5 lb HDPE).

The two-platen clamp has tiebar clearance of 42 × 42 in. and usable mold space of 60 × 42 in. Hydraulic ejection is standard.

Related Content

-

Best Methods of Molding Undercuts

Producing plastics parts with undercuts presents distinct challenges for molders.

-

How to Reduce Sinks in Injection Molding

Modifications to the common core pin can be a simple solution, but don’t expect all resins to behave the same. Gas assist is also worth a try.

-

Know Your Options in Injection Machine Nozzles

Improvements in nozzle design in recent years overcome some of the limitations of previous filter, mixing, and shut-off nozzles.