First Commercial Recycling Process For Electronics Waste

A 23-year-old Dutch plastic recycling firm, Plastic Herverwerking Brabant (PHB) BV has become the first supplier in the world of a complete commercial altered-density-media system tailored to separate the plastics in waste electrical and electronic equipment (WEEE). Since last October, PHB has operated a WEEE recycling system sized for 33 million lb/yr and averages about 4400 lb/hr of reclaimed material from 11,000 lb/hr of waste input.

A 23-year-old Dutch plastic recycling firm, Plastic Herverwerking Brabant (PHB) BV has become the first supplier in the world of a complete commercial altered-density-media system tailored to separate the plastics in waste electrical and electronic equipment (WEEE). Since last October, PHB has operated a WEEE recycling system sized for 33 million lb/yr and averages about 4400 lb/hr of reclaimed material from 11,000 lb/hr of waste input. The relatively small proportion of recaptured saleable material pays off because it includes about 10% valuable metals—mostly copper, but also gold. PHB has been recycling WEEE plastics since 2002. It builds commercial recycling machinery through a separate business called Envirotec BV in the same location.

Only two other known recyclers process exclusively WEEE plastics: MBA Polymers, headquartered in the U.S. does so commercially in China and Austria. Axion Recycling Ltd. in the U.K. is in the developmental stages. But neither of these two firms’ technology is for sale. MBA only offers its proprietary system design to joint ventures; and Axion’s process, developed with the Fraunhofer Institute in Germany, is still developmental and involves licensing (see Learn More).

Among other machine builders, Turbo Laminare Trenntechnik in Germany also builds a recycling system for WEEE, the first of which was installed last year at metals reclaimer TBS (Technische Behandlungssysteme GmbH) in Enns, Austria. Like the PHB system, it uses altered-density separation, but is designed to process a blend of WEEE and auto shredder residue. Also, it yields a blend of PS and ABS, whereas PHB recovers separate streams of PS, ABS, and flame-retardant materials (PC and ABS).

PHB’s Envirotec division has sold three complete WEEE recycling plants to customers in the U.K., France, and Japan. The first of these is expected to be up and running in the U.K. this summer. Envirotec also sold a half-dozen installations of individual WEEE recycling components like float/sink tanks or water-treatment systems, and has also supplied technical designs for customers to build their own systems. Envirotec uses PHB’s full-scale WEEE recycling line for customer trials.

ALTERED-DENSITY SEPARATION

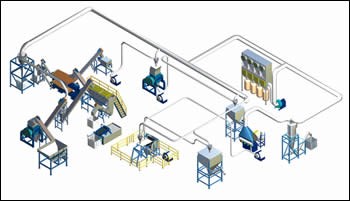

The Envirotec line starts with a binful of shredded WEEE plastic with more than 50% contamination from nonferrous metals, glass, stones, urethane foam, etc. The waste is auger fed at 11,000 lb/hr onto a belt conveyor. The belt feeds it into an elongated box where a high-speed, high-torque rotor with paddles turns at 3000 rpm. The rotor beats the flake against a screen cage, removing most of the surface dirt, sand, rocks, and foam in seconds.

Flake then goes onto a large (1.5 x 4.5 meter) inclined tray with a washboard-like, grooved surface. Water sluices over the left half of the board, washing the plastic flake down. Heavier metals stay in the grooves and move off to the right. The plastic flake is taken by auger to a granulator to grind the material into 10 mm particles. (PHB uses a Rapid grinder.)

Flake next goes into the first float/sink tank, which is filled with plain water. PE and PP float off and are sold as a mixture of roughly 60/40 PE and PP. Meanwhile, PS, ABS, and flame-retardant materials sink. These “sinks” go into Tank 2, containing an aqueous solution of 1.035 g/cc density, as well as three rotating drums with paddle vanes. PS floats in this tank, while ABS and FR materials sink.

The ABS and FR plastics go into a third tank, longer than the first two, and equipped with four drums having paddle vanes. Tank 3 has a 1.07 density water solution in which ABS floats, while FR materials sink. The FR PC and ABS are a compatible blend, which PHB sells for applications like electrical boxes and adjustable feet for leveling kitchen cabinets.

PHB also runs recycling lines in adjacent plants for PP from car batteries, wire/cable scrap, and PS from refrigerators. Annual production from all recycling lines at PHB is about 60 million lb/yr. “For now, most machinery sales, and the most interest, is for the WEEE line,” says Edwin Visser, commercial manager of PHB.

WATER TREATMENT

PHB/Envirotec’s process can’t handle waste plastics with food or chemical contamination, which has to be pre-washed. Any grease or fat throws off the density separation and keeps afloat materials that would normally sink. More important, it plugs the water filtration and treatment system, which is critical to Envirotec’s WEEE recycling process. Ground-up computer housings, vacuum cleaners, cell phones, refrigerators, and other used appliances don’t require pre-washing.

“Water filtration is the heart of the system,” says Marinus (“Rien”) Driessen, founder of PHB and managing director of Envirotec. The closed-loop system never changes the water column, but continuously filters out particulates with fine nylon mesh. The filter is a continuous revolving belt, cleaned at one end by high-pressure water jets. Particulate matter is pushed backward off the belt by the water jets as water passes through. At the far end of the belt, drained particulate matter is knocked off the belt by a rotating brush and removed by an auger.

The water is automatically and continuously monitored for temperature, density, level, and flow rate at all the altered-density media stages. Because the system is closed-loop, only about 10 gal of make-up water is added per hour to replace evaporation and water removed with the flakes and contamination. For 4400 lb/hr of output, water usage is about 0.0025 gal/lb of plastic. The entire system holds about 1000 gal of water in all three tanks, the water sluice, and water-filtration system.

Related Content

Vecoplan Opens New Location in Southern California

The company’s new office will allow the company to more effectively service customers in the country’s western region.

Read MoreNew Facility Refreshes Post-Consumer PP by Washing Out Additives, Contaminants

PureCycle prepares to scale up its novel solvent recycling approach as new facility nears completion.

Read MoreInside the Florida Recycler Gearing Up to Take on Scrap at NPE2024

Hundreds of tons of demonstration products will be created at NPE2024 next spring. Commercial Plastics Recycling strives to recycle all of it.

Read MoreCompatibilizers Aid Recycling & Upcycling of Mixed Resins

Compatibilizers are proving their worth in boosting critical properties such as impact/stiffness balance of PCR and PIR blends of polyolefins and other plastics.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE 2024.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More