Consistent Shots for Consistent Shots

An integral supplier in the effort to fast-track COVID-19 vaccine deployment, Retractable Technologies turned to Arburg and its PressurePilot technology to help deliver more than 500 million syringes during the pandemic.

Before and after shots of Retractable Technologies Inc.’s VanishPoint syringe. Source: Retractable Technologies Inc.

“We had to have machines right away, and we had to have molds right away to help combat the pandemic,” says Larry Salerno, director of operations at Retractable Technologies Inc. (RTI), Little Elm, Texas.

RTI designs, manufactures and markets safety syringes and other safety medical products. In 2020, its VanishPoint syringe design was fast-tracked as part of the Operation Warp Speed effort to rapidly mobilize sectors of the manufacturing industry. At that time, RTI purchased and installed many Arburg presses and added 40,000 ft2 of additional cleanroom space, along with supporting material handling and assembly equipment.

All the installed Arburg machines utilize the company’s PressurePilot to automatically optimize the molding process’ pressure profile. “The benefit we realize from PressurePilot is better consistency and increased customer satisfaction,” Salerno says. “We have a tighter capability potential (CP) and CPK. And, in addition to better consistency, we now make fewer adjustments to the process because we have better control over it.”

The syringes used for vaccines measure just a quarter of an inch in diameter but must maintain tolerances of ± .001 or ± .002 inch. Molded from a 96-cavity tool, the syringe applies PP for the barrels and plunger handles, and a TPV for a friction-ring gasket and plunger plug, which seals the medication into the barrel. The entire syringe consists of seven molded parts: barrel, handle plunger, handle cap, needle cap, friction ring, plunger plug and plunger seal.

A mechanical device with a delicate and important function, the syringe’s “friction fit” is key. “Our particular product is friction fit,” explains RTI’s Jordan Duesman. “So the way the product functions means we have to hold very tight tolerances, and we found that the PressurePilot helps maintain those specifications.”

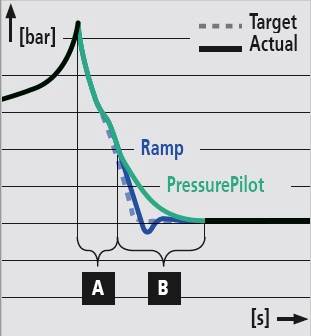

Arburg says the PressurePilot function of its Gestica machine control makes a nonlinear automatically optimized pressure profile possible, enlarging the process window and providing more balanced fill. PressurePilot’s automatically generated curve progression eliminates pressure drops or loss by initially reducing pressure abruptly but then ever more slowly. The dynamic, rapid pressure reduction helps avoid internal pressure peaks inside the cavity that could prompt overfilling and flash.

RTI estimates that it uses PressurePilot on roughly 90% of the jobs it runs on its Arburg presses, boosting pressure by up to 250%. In these instances, the company says PressurePilot prevents the screw from bouncing back during pressure changes from boost to hold. “This is an ideal situation for the PressurePilot control,” Salerno says. “Some boost-to-hold pressures show a significant change, and it definitely helps with that situation.”

Salerno says the “functionality force” and friction generated by the tight tolerances between plunger and barrel wall are key. “In addition to the friction technology holding the pressure against leakage of the medication,” Salerno explains, “the syringe also has to trigger under a certain amount of force so that the pressure on the thumb feels right for the health care worker, but not so low that the medication blows out or leaks during usage.”

In addition to safety, RTI’s syringes have very little “dead space,” enabling users to get six doses of medicine from a five-dose vial. The VanishPoint products also have fixed needles and come ready-to-use, so its customers do not waste time attaching, changing or recapping needles.

“During the pandemic, people were getting vaccinations everywhere,” Salerno says, emphasizing his company’s needles ease of use. “You were going to stadiums and sitting in your car and having the health care worker give a shot while you're still sitting in the car.”

RTI has been manufacturing its patented technology retractable syringe to protect against needlesticks (that can spread HIV, hepatitis and other bloodborne diseases) since 1997. Nearly 25 years later, the government called on the company for assistance in a public health crisis.

At this point, Salerno estimates that RTI has molded around a half billion parts on the new Arburg equipment. “The government wanted the ability to have a syringe for every person in the U.S. within a year,” Salerno says, “so we have a considerable amount of capacity.”

Retractable Technologies turned to Arburg and its PressurePilot technology to help meet the demand for vaccine syringes. Source: Retractable Technologies Inc.

Related Content

Foam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

Read MoreHow to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.

Read MoreIn Sustainable Packaging, the Word is ‘Monomaterial’

In both flexible and rigid packaging, the trend is to replace multimaterial laminates, coextrusions and “composites” with single-material structures, usually based on PE or PP. Nonpackaging applications are following suit.

Read MoreSolve Four Common Problems in PET Stretch-Blow Molding

Here’s a quick guide to fixing four nettlesome problems in processing PET bottles.

Read MoreRead Next

Hardware/Software Package for Processing Recycle

Arburg has combined plasticating-unit features and selected adaptive-control functions into a package to enable more consistent processing of recycled materials.

Read MoreOptimized Pressure Control for a More Repeatable Process and Parts

New software from Arburg automatically determines the ideal ramp of the injection-to-hold profile.

Read MoreArburg Updates Machine Control

Arburg announced a series of updates to its Gestica conrol platform, including the addition of new “assistants” and “pilots.”

Read More