How to Keep Your Conveyor Running Smoothly

Low-profile conveyors are ubiquitous in industry, typically used in 24/7 applications in packaging, assembly, labeling, inspection, and sorting. Here's how to keep them up and running.

Low-profile conveyors are ubiquitous in industry, typically used in 24/7 applications in packaging, assembly, labeling, inspection, and sorting. These are compact belt conveyors with 1- to 2-in. pulley diameters and maximum belt widths of 24 in. They form critical production links where unplanned downtime or time-consuming maintenance is intolerable.

The most critical areas of low-profile conveyors that draw maintenance attention are the belt itself and the pulley/bearing system. Speed, load, accumulation, and inclined operation increase forces on these components and on the drive system, highlighting problem areas such as belt tension.

Belt manufacturers universally cite correct belt tension and crowned pulleys as keys to long belt life and consistent slip-free performance with positive self -tracking. Incorrect belt tension is responsible for a high percentage of component-related failures and maintenance cost. Incorrect belt tension can cause many problems, including bearing overload, miss-tracking, belt slippage., etc.

Correct tension varies with the application, but typically it will be 1 mm of belt stretch per foot of conveyor length. However, with allowable manufacturing tolerances on belts, a belt will normally be a little longer or shorter than its stated size. To ensure correct tensioning, a simple system has been developed to allow maintenance people, and even novice operators, to set correct tension in seconds.

The system uses the tail pulley to set tension. Once all belt slack is taken up, tension is set via a scale on each side of the conveyor, where each increment represents the tension setting/ft of conveyor length. It seems counterintuitive, but a belt that is under-tensioned can actually elongate in use, which leads to many belts in good condition being discarded, due to a conveyor’s limited tensioning capacity.

CENTERING WITH CROWNED PULLEYS

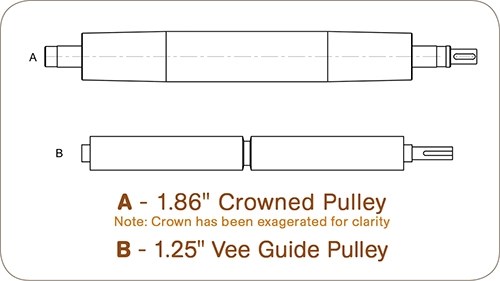

Following the recommendations of the major belt manufacturers, a crowned pulley with a correctly tensioned belt is the preferred way to achieve automatic belt centering. A crowned pulley produces dual lateral opposing belt forces, which balance each other when the belt is centered over the crown. If the belt moves off center, these lateral opposing forces become unbalanced, resulting in the “higher force” side directing the belt back to its centered position. This action provides virtually wear-free centering. Crowned pulley systems also allow higher accelerations and speeds with much less belt and component wear.

Properly tensioned belts on crowned pulleys easily withstand moderate short-term lateral forces without major displacement from center. When side loads increase, a V-retainer on the underside of the belt can be added to limit off-center drift. The V-shaped profile rides in a groove cut into the pulleys (which reduces pulley rigidity), and a groove running the length of the conveyor bed. This approach allows the crowned pulley to quickly center the belt when the external force is removed, minimizing wear on the V-retainer.

Belt manufactures recommend that V-retainers should not be the primary belt-tracking system due to the high wear the V-profile incurs. If the lateral force is sufficient, the V-retainer will climb out of its groove, and may damage the belt. An alternative is to use the V-retainer on the top edge surface of the belt and have it guided and constrained from the top down by a rolling V-guide made of acetal plastic (such as DuPont’s Delrin), located opposite the point where the belt experiences side forces. These guides keep the V-profile fully constrained with reduced wear.

A normal V-retainer alone does not offer true “non-contact guiding” so it tends to drag against the sides of the groove and wear constantly. Another point to consider on a bottom-mounted V-retainer is that the weld used to attach it results in a slight high spot in the middle of the belt, which can be troublesome if the belt carries small products that are prone to tip over. Because of material incompatibilities, the V-profile cannot be used with certain types of belts, such as those based on silicone, PTFE, or polypropylene.

PULLYS: SIZE MATTERS

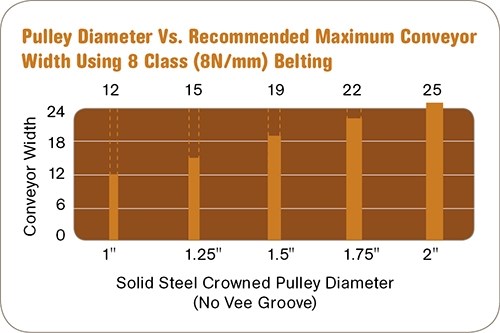

As noted, low-profile conveyor pulleys normally range from 1- to 2-in. diam., but this small range can produce a surprising difference in conveyor capacity and performance, as well as belt, cleat, and bearing life. Smaller pulleys may be needed for applications requiring a minimum height and moderate speeds and loads. However, logic dictates that a smaller-diameter drive pulley will have a much greater tendency to deflect as the conveyor width increases (a 1.25-in. pulley without a V-groove will deflect nearly five times more than a 1.86-in. pulley with the same load). This creates an inherent “traction” disadvantage for load-carrying purposes, and can negate the crowning effect (belt-centering capability) of the pulley. This is highly problematic in applications that involve wider conveyors, reversing, accumulating, or inclined operation. Flexing a belt over a smaller diameter also accelerates the breakdown of the belt structure, leading to erratic operation and shorter life.

When scaled up in width, conveyors with small-diameter pulleys often cannot carry proportionally greater loads. For example, a conveyor with a pulley diameter of approximately 2 in. and a correctly tensioned belt will carry twice the load at 24 in. wide that it does at 12 in.wide. This rule of thumb does not hold as pulley diameters approach the 1.25-in. range (see chart on p. 44).

Smaller pulley diameters—with their greater tendency to deflect—have limited ability to produce the proper belt tension to achieve automatic centering with a crowned pulley. The resulting loss of “traction” and self-centering are sometimes compensated for by lagging or knurling the pulley and substituting a longitudinal V-retainer for a crowned pulley. Because the pulley must now have a V-groove in its center, as well as being knurled, its rigidity is further compromised.

Belt manufacturers, too, discourage knurled pulleys because they invariably abrade the belt’s underside and resist tracking, which leads to a substantial reduction in belt life. Impacted debris in the pulley knurl or worn knurling can lead to belt slippage and miss-tracking, as well as accelerated wear of the belt, V-retainer, and pulley knurl. Abrasion can occur without any load on the conveyor, and it increases with belt speed. Debris from this abrasion may be unacceptable in food, pharmaceutical or cleanroom applications. Routine cleaning of the knurls is impractical because it requires stopping production and removing the belt.

Bearing life is also greatly affected by pulley diameter. A 1-in. pulley must run at twice the rpm of a 2-in.-diam. pulley to produce an identical belt speed. Small pulley diameters can result in smaller bearings with lower load capacity running at higher speeds, reducing service life. Ensuring that the bearing outer race cannot rotate in the bearing plate housing can improve bearing performance and avoid the need to replace worn bearing housings.

Drives are available in a wide variety of styles. One that is gaining popularity is the external shaft-mounted design. This unit is compact, provides “perfect alignment,” and eliminates all couplings, drive belts, chains, sprockets, guards, and tensioning. These drives can be radially positioned in 30° increments. and can be exchanged in less than 5 min when equipped with an optional plug connector.

If a conveyor is used for multiple applications at different speeds, a variable-speed drive may be desirable. This reduces wear and power consumption, and provides optimum speed for each application.

The service manual for a conveyor can give clues on preventive maintenance and troubleshooting. For example, does the manual recommend stocking spare pulleys, bearings, and bearing plates? Or disassembling and checking bearings during a belt change or cleaning knurled pulleys? Belt-change time should be based on the conveyor in its operating position, not resting on a bench.

Manufacturers offer a broad range of options such as cantilever stands and tool-less guide-rail and belt-support removal and belt release that can permit a “one-minute” belt change on a stand-mounted conveyor. These options should be reviewed with the manufacturer, especially if downtime is a critical factor.

Related Content

Improve The Cooling Performance Of Your Molds

Need to figure out your mold-cooling energy requirements for the various polymers you run? What about sizing cooling circuits so they provide adequate cooling capacity? Learn the tricks of the trade here.

Read MoreThe Importance of Melt & Mold Temperature

Molders should realize how significantly process conditions can influence the final properties of the part.

Read MoreSolve Four Common Problems in PET Stretch-Blow Molding

Here’s a quick guide to fixing four nettlesome problems in processing PET bottles.

Read MoreThe Strain Rate Effect

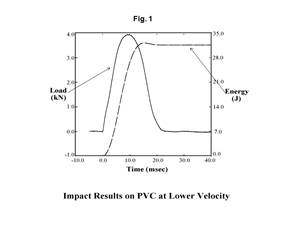

The rate of loading for a plastic material is a key component of how we perceive its performance.

Read MoreRead Next

Recycling Partners Collaborate to Eliminate Production Scrap Waste at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair will seek to recover and recycle 100% of the parts produced at the show.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE 2024.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More

(2).jpg;maxWidth=300;quality=90)