Intouch Monitoring: Scheduling and Analytics System for Increased OEE

Make more products with the same or fewer resources, allowing you to be more competitive without sacrificing quality or profit. (Sponsored)

Intro (00:00)

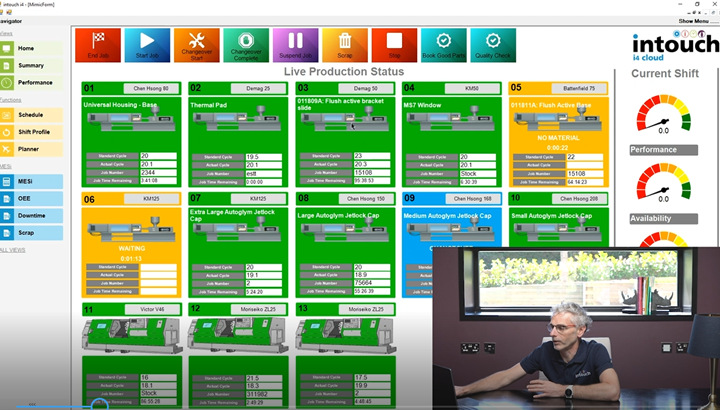

Real-Time Dashboards (00:40)

Operator Job Control (06:36)

Scheduling (08:38)

Reporting (13:04)

Outro (19:30)

John, MD of Intouch talks you through how to use the Intouch i4 Cloud and what benefits you can expect.

Intouch Manufacturing Execution System (MES) monitors, manages and brings together all the different parts involved in production.

It gives you accurate, real-time data that allows for the right questions to be asked at the right time.

With that information, you can be proactive, rather than reactive and those timely decisions increase productivity, improve OEE and increase profit, whilst maintaining quality.

Make more products with the same or fewer resources, allowing you to be more competitive without sacrificing quality or profit.

Intouch is made up of several components: A monitoring module that shows what is happening in the factory in real-time; a live scheduling module that allows the planning and scheduling of jobs and a reporting and business analytics module that provides accurate reports so that any patterns are easily spotted and changes that need to be made are obvious.

Intouch is a scalable SaaS system that is easy to learn and integrates with any ERP system.

Since 1997 and in 300 sites worldwide, we are proud of our exceptional customer service.

For more information on this and other Intouch Monitoring products, visit Intouchmonitoring.com and follow them online on Twitter, Facebook, and LinkedIn.

(1).jpg;maxWidth=970;quality=90)