Italian Machine Builders Bandera, Macchi Running Film Lines

Five layer lines running all polyethylene as part of sustainability push.

Italian machine builders Luigi Bandera and Macchi are bucking the trend among suppliers of blown film machinery by running production lines during NPE2024.

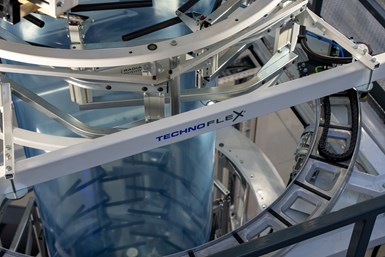

In the case of Macchi, NPE2024 marks the first time ever it will run a line at a show outside Europe. The machine builder, which recently opened a new office in the U.S. in Charlotte, N.C., will operate its 5-layer TechnoFlex line in Orlando May 6-10, running a variety of polyolefin-based structures for shrink film, lamination, printing and gusseted film.

At the show, Bandera will be running a thickness from 20 to 200 μm at output rates of 880 lbs/hr. The line was shipped to the show after it debuted at an open house in January at Bandera’s headquarters in Busto Arsizio, Italy (near Milan). It will be available for sale right from the show floor, says Mattia Gambarotto, general manager of Bandera’s North American operation.

While builders of injection molding and blow molding machinery conventionally operate machines at trade shows, many manufacturers of extrusion lines have trended toward static displays — in particular at NPE, but of late at the K Show as well — due to cost, line size and complexity, more restrictive ceiling heights, potential processing complications and numerous other factors.

Bandera, however, decided to invest in running an actual blown film line at the show as a means to demonstrate its commitment to the North American market, Gambarotto notes. “Compared to other European suppliers of blown film technology, our decision to invest in the North American market came a little later, so we feel that demonstrating our capabilities at a show like NPE is important given our new organization in North America and our plan to increase brand awareness,” he says.

The line features a 20-component gravimetric dosing system with an automatic cleaning system; 5 extruders (one 85 mm; the other four 65 mm); a 5-layer 300-mm coextrusion die head with IBC; a high-efficiency dual-lip air ring; automatic film thickness control; flattening and gusseting devices; calibration cages; an oscillating haul-off, 1,800-mm roller width; the company’s Trim Flex edge-reclaim system; a two-station face-to-face winder featuring contact/axial winding modes with automatic reel extraction; and a complete tower frame. The line is designed and supplied on 480-volt components.

Says Gambarotto, “Nowadays when someone purchases a blown film line and invests millions, they want to be sure not only about the technology but also about the company they are buying from, how strong it is, how committed they are to the market. We’re confident that what we will be demonstrating will be interesting to the audience and also be positive for Bandera.”

Meantime, Bandera’s new 6,000-square-foot facility in Charlotte will house sales, spare parts and service support.

Macchi has run lines at the last several NPEs. This week, it’s running a 5-layer polyolefin-dedicated line featuring 5 extruders; a continuous flow hydraulic screen changers to better accommodate the introduction of reclaim; a triple-flow air ring with and integrated automatic profile control system; a wax drainage system for the air ring; a frost line scanner; a smoke suction system on bubble guide; a Centro Freeze supporting basket with cooling function; a double station automatic winder; and an inline system for side trim recovery.

What’s more, the line is furnished with Macchi I.o.T., a digital solution that performs OEE monitoring, breakdown analytics and predictive maintenance to verify production efficiency in real time. Also in action is the Macchi W.i.S. (Web Inspection System), an innovative solution for film defects mapping.

Related Content

Polyethylene Fundamentals – Part 4: Failed HDPE Case Study

Injection molders of small fuel tanks learned the hard way that a very small difference in density — 0.6% — could make a large difference in PE stress-crack resistance.

Read MoreNew Entrant Heartland Polymers Stepping up as Reliable Supplier

Heartland Polymers’ new Alberta, Canada facility will produce 525 KTA propylene and 525 KTA polypropylene. It is expected to stabilize supply chains across the continent.

Read MoreFundamentals of Polyethylene – Part 6: PE Performance

Don’t assume you know everything there is to know about PE because it’s been around so long. Here is yet another example of how the performance of PE is influenced by molecular weight and density.

Read MoreImproving Twin-Screw Compounding of Reinforced Polyolefins

Compounders face a number of processing challenges when incorporating a high loading of low-bulk-density mineral filler into polyolefins. Here are some possible solutions.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More

(2).jpg;maxWidth=300;quality=90)