New Tech Center Shows Off New Injection Presses

Facility features a variety of machines from Yizumi-HPM for the U.S. market.

Just last month, HPM North America Corp., a member of the Yizumi Group of China, moved its sales, engineering, and administrative headquarters from Marion, Ohio, to a 28,000-ft2 Yizumi-HPM technical center in Iberia, Ohio. Assembly, remanufacturing, and die-cast machine manufacturing operations will remain in Marion.

The new facility is equipped with a high-bay area and 25-ton bridge crane to support its function as a demo center for Yizumi HPM injection machines. According to Bill Duff, HPM general manager of sales and marketing, “This new facility, totally rehabbed at a cost of several million dollars, expresses the company’s commitment to the North American market.”

Redesigning machines specifically for this market is another sign of that commitment, Duff added. Seven of its latest models, most of them new releases, were on display at an open house in mid-October to illustrate the range of the company’s offerings.

Duff says HPM now has over 20 sales representatives in North America. The firm has sold over 60 machines since its return to the market under Yizumi ownership in 2012, and is on track to sell 25 machines this year.

NEW MACHINES TAILORED FOR U.S.

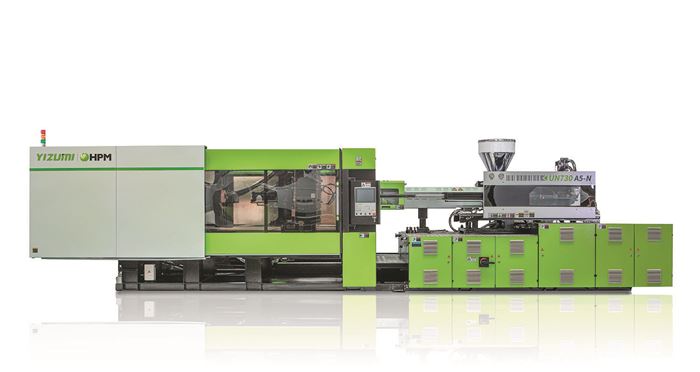

Exemplifying the revision of Yizumi products to meet North American needs and standards is the model UN720A5-N toggle press with servohydraulic pump. This 720-ton (U.S.) member of the new A5-N (N = North America) series has platens with U.S. platen mold-mounting patterns, Bosch Rexroth hydraulics, new KEBA touch- screen controller from Austria, and U.S.-designed control software. It has a larger hydraulic power unit for higher speeds. This series ranges from 65 to 1150 tons and includes new series (and others in HPM’s line) is also available as hybrids with electric screw drive.

These are the other machines currently on display at HPM:

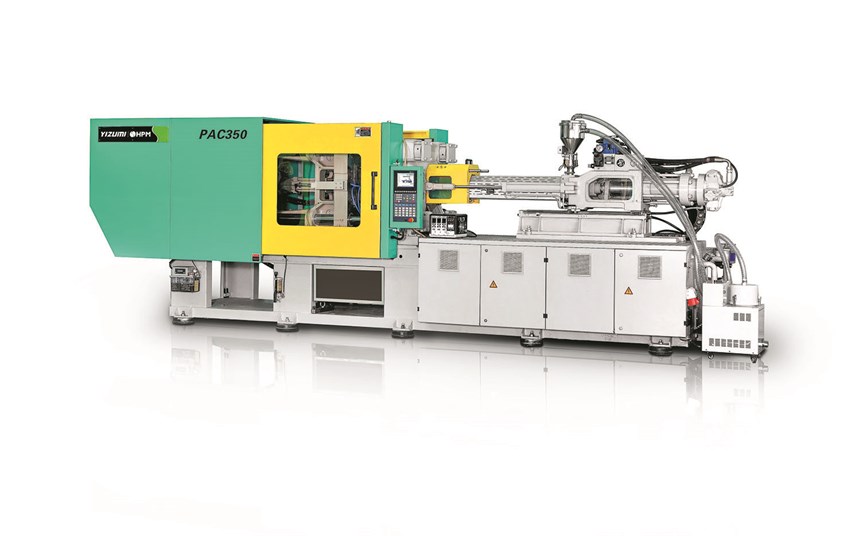

• The PAC-350 (350 tons) is a high-speed packaging machine based on the A5-N line. It incorporates an accumulator and an upgraded servohydraulic power pack to permit simultaneous clamp and screw motions. At the open house, it ran a four-cavity container lid mold in under 5 sec. PAC models range from 150 to 450 tons.

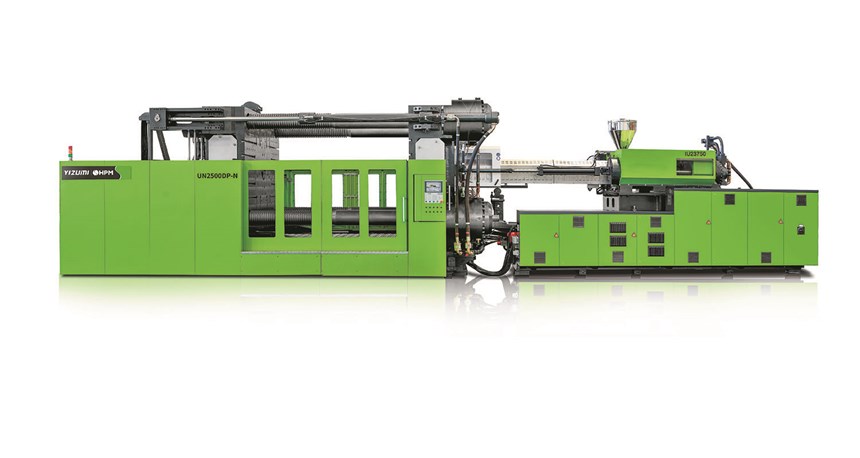

• A 1650-ton model UN1650-18500DP-N servohydraulic, two-platen press is an example of a new “North American” series from 880 to 3500 tons. It has a KEBA control system like the A5-N series; in fact, Duff notes that all HPM machines now have a common controls format.

• Two models of the HST2 servohydraulic toggle presses are at the new tech center. Upgraded with more power and new control software, they are successors to the HST line that was introduced in 2015 and shown at NPE that year. They range from 60 to 720 tons. Duff says they will gradually be replaced by the A5-N line over the next two years.

One model at the tech center is an HST2-440 (440 tons) with a gas-assist system supplied by Linde North America, Inc., Murray Hill, N.J. This system gets its gas supply from evaporation of liquid CO2; the low temperature of the gas reportedly helps minimize cycle times. This press also will demonstrate the new CoPilot process monitoring system from RJG, Inc., Traverse City, Mich.

Also on display is an HST2-65-LIM, a 65-ton press outfitted for LSR with a two-component metering system and static mixer from Elmet North America, Inc., Lansing, Mich. Duff notes that LSR is a new area for Yizumi, and this system was developed in the U.S.

Yizumi-HPM’s latest all-electric line is the FE-N series from 65 to 360 tons. These also are built to North American design criteria. The tech center has an FE60 (65 tons).

• The new tech center also features two vertical-clamp rubber injection presses, YL2-V280L and YL2-V350L. Like other models, these servohydraulic presses have KEBA controls.

Though details have not been finalized, Duff says HPM will exhibit three machines at NPE2018 next May in Orlando, Fla., and one or two more will be running at other booths, such as Linde’s.

Related Content

Fakuma 2023: Wittmann Battenfeld Expands All-Electric Line, Direct-Current Capabilities

Wittmann Battenfeld will introduce the new EcoPower B8X injection molding machine line and show direct current as an energy source for a concept machine that will power its own robot.

Read MoreFakuma 2023: More Details on New Machine Line

Wittmann Battenfeld has released more details on the new EcoPower B8X debuting at Fakuma (October 17-21; Friedrichshafen, Germany), which it previously announced.

Read MoreConsistent Shots for Consistent Shots

An integral supplier in the effort to fast-track COVID-19 vaccine deployment, Retractable Technologies turned to Arburg and its PressurePilot technology to help deliver more than 500 million syringes during the pandemic.

Read MoreIPEX Opens Injection Molding Facility in North Carolina

The pipe and fittings manufacturer’s new 200,000-square-foot facility represents a $200 million investment and will create 150 jobs.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE 2024.

Read More