News in Medical Tubing & Materials

Close Up: Medical Plastics

Two innovations in medical tubing and more than a dozen new materials, coatings, and adhesives were on display at June’s Medical Design & Manufacturing (MD&M) East show in Philadelphia.

Two innovations in medical tubing and more than a dozen new materials, coatings, and adhesives were on display at June’s Medical Design & Manufacturing (MD&M) East show in Philadelphia. Here’s a quick rundown of these developments:

ADVANCES IN TUBING

In the last couple of years, Teleflex Medical OEM, Gurnee, Ill., became one of the first to coextrude medical tubing using EFEP fluoropolymer and nylon 12 or PEBA-type TPEs. Unlike other fluoropolymers (PTFE and FEP) used to provide lubricity in multi-layer tubing for applications such as catheters, EFEP bonds well with polyamide-based resins without the need for chemical etching. That preserves clarity, which is sacrificed by etching, and also saves a manufacturing step and the attendant cost. EFEP reportedly adheres both to other plastics and to wire coil or braid reinforcements without risk of delamination.

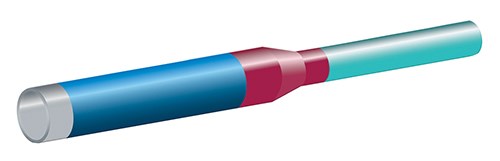

Sources at Daikin America, Inc., Orangeburg, N.Y., the only supplier of EFEP, says other tubing manufacturers are now developing products based on this concept. A second innovation from Teleflex Medical OEM, which came on the market last fall, is an overmolding process for joining tubing segments of different diameters. The usual approach is heat-shrinking a segment of bonding material over the joint between the two tubing components in devices such as catheters. This has the drawback of creating a rigid bond site that limits catheter flexibility. The new approach allows the transition section to be rigid or flexible as desired without interfering with the strength of the mating tube components. Overmolding also allows joining tubes of wider diameter differences (beyond the usual 1.1:1 ratio), the company reports.

NEW MATERIALS, ADHESIVES, COATINGS

Thermoplastic elastomers were the most numerous category of materials introduced at MD&M East. Teknor Apex Co., Pawtucket, R.I., unveiled what’s said to be the first medical-grade TPEs that can be calendered. Calendering reportedly provides better thickness uniformity, more consistent physical properties, and greater thermal stability than film extrusion. While previous TPEs reportedly have not performed well in calendering, Teknor fine-tuned the rheology of its Medalist MD-500 Series TPEs for this process in collaboration with O’Sullivan Films, Winchester, Va. Teknor also worked with Genesis Plastics Welding, Indianapolis, to show that MD-500 TPEs can be radio-frequency (RF) welded. Teknor says its TPEs have proven to be “fully comparable to PVC in processing, bonding, assembly, and clinical handling.” This development is said to eliminate the usual disadvantages of TPEs vs. PVC in film applications such as fluid drainage and storage bags, cushioning bladders, and surgical pouches.

Teknor says its Medalist MD-500 Series offers the same strength as PVC in films one-half as thick. Combined with 30% lower density than PVC, TPE films can be up to 70% lighter than PVC and lower in cost. In addition, Medalist MD-500 resins are available in lower hardnesses than flexible PVC and reportedly provide a broader processing window, greater elasticity and tear strength, better low-temperature flexibility and toughness, and lower permeability to nitrogen and moisture.

Lubrizol Corp., Cleveland, brought several new TPUs to the show. It has expanded its Tecothane Soft series of clear, aromatic products from one to four grades spanning a hardness range of 62A to 97A. Adding harder versions opens up a broader range of applications, including larger catheters and extension tubing. These TPUs feature low density and better alcohol and chemical resistance than standard TPUs.

Lubrizol also expanded its Pellethane line of TPUs with eight new medical aromatic grades for wound care, medical garments, film, and tubing. These include two polyester and six polyether products that offer high moisture vapor transmission rates, stiffness and non-kinking properties, and lower swell than other TPUs.

Other Lubrizol introductions included eight new aromatic Carbothane TPUs to complement existing aliphatic grades in the series. Aromatic versions of these polycarbonate-based TPUs are said to be stronger and more resistant to chemicals and creep.

Also new was a non-halogen flame-retardant system available across its TPU line, said to be the first for these materials to offer an LOI of 30 and either glossy or matte finish. It also exhibits low smoke and toxicity, the company says.

Foster Corp., Putnam, Conn., introduced ProPell TPU and PEBA compounds for catheters that are said to dramatically reduce tackiness and friction in soft, flexible polymers without compromising physical properties. Dry coefficient of friction was reduced 66% for a TPU of 80 Shore A and 84% for a PEBA of 35 Shore D.

New from the Engineered Polymer Systems (EPS) Div. of Parker Hannifin Corp., Salt Lake City, is an aliphatic polycarbonate-based TPU with not only the expected resistance to oxidation and alcohol swelling, but also improved ESCR. Parker Medical Grade ALC Polyurethane is offered in clear or radiopaque grades.

Recent developments from RTP Co., Winona, Minn., include MD Series medical-grade TPEs that show good adhesion to other thermoplastics in overmolded seals, grips, and buttons. The RTP 2700 S MD Series of styrenic TPEs bonds to PP and comes in 30A to 80A hardness. RTP 6003 and 6042 MD Series specialty TPEs (44A to 70A) bond to ABS, PC, PC alloys, PBT, and rigid TPU (RTPU).

RTP also has new MD grades of antistatic/static-dissipative compounds that offer transparency as well as rapid charge dissipation (5 kV in less than 2 sec). Resins include PP, acrylic, clear ABS, and cylic olefin copolymer (COC). All MD grades are tested for biocompatibility and meet ISO 10993 specs. Colors are available (masterbatch or precolor).

Techmer Engineered Solutions, Clinton, Tenn., also has new silver-based antimicrobial products, available in a variety of colors and resins—polyolefins, nylons, polyesters, PC, etc. Also new are laser-markable grades and gamma-stable colors and additives for PC.

The Medical Devices unit of BASF New Business, Tarrytown, N.Y., expanded its HyGentic series of antimicrobial compounds containing silver. To its existing nylon 6 and SBC (styrene-butadiene block copolymer) grades, BASF added HyGentic SA styrene-acrylic copolymer, based on its Xylar resin.

Sheet extruder Goex, Janesville, Wis., introduced Medex 641 sheet based on a a proprietary styrenic alloy for rigid medical and pharmaceutical packaging. Its low density (1.015 g/cc) offers a yield advantage over PVC, PETG, and PC. Available in rollstock of 0.010 to 0.050 in. thickness, it’s said to be clear, tough, and ETO or gamma sterilizable; and it seals to standard Tyvek lidding materials.

Also new from Goex is medical-grade PETG, PS, and PP sheet containing additives said to make medical packaging biodegradable in biologically active landfills. The Eco-One organic additives are supplied by Ecologic, LLC, Oakbrook Terrace, Ill. They are said not to alter the appearance or physical/mechanical properties of the product and are not affected by ETO or gamma sterilization.

A new liquid silicone rubber (LSR) for injection molding is MED 5440 from NuSil Corp. LLC, Carpinteria, Calif. This is a 100% fluorosilicone grade (40 Shore A) for O-rings, seals, gaskets, and precision molded parts. Fluorosilicone contributes high resistance to absorption and swelling in contact with solvents and silicone oils. Also relatively new are thermally conductive LSRs: MED15-2980 (70-80A) and MED-2955 (40-55A). A new series of standard USP Class VI grades (50A, 60A, 70A) for high-volume, lower-cost applications is in development.

Wacker Chemical Corp., Adrian, Mich., is offering new grades of restricted implantable LSRs in its Silpuran line.

NuSil and Wacker also have new silicone adhesives and sealants for bonding cured silicone rubbers to textiles and other materials: NuSil’s MED 1555 100% fluorosilicone and MED 1540 low-viscosity silicone; and Wacker’s Silpuran 2438 ADH A/B.

New medical coatings also were on display:

•Microcare Medical, New Britain, Conn., introduced Duraglide ISO 10993 certified dry lubricant in aerosol form. It deposits microdispersed PTFE onto catheters, hypotubes, and medical instruments that need lubricity.

•New from Specialty Coating Systems (SCS), Indianapolis, microResist is a said to be a “breakthrough” in parylene coatings for medical devices in that it adds antimicrobial action to parylene’s dry-film lubricity and barrier protection.

•A relatively new acqueous coating, Diofan Super B, is said to double the moisture and oxygen barrier properties of standard PVDC coatings for pharmaceutical blister packaging. Solvay Specialty Polymers, Granville, Ohio, says it’s transparent and easily thermoformable.

Related Content

Benchtop LSR Injection Molding Machine Launches

APSX LLC, which previously marketed the APSX‑PIM desktop thermoplastic injection molding machine, has debuted the APSX‑LSR — a benchtop liquid silicone rubber (LSR) injection system.

Read MoreArterex Acquires Italian Medical Device Provider

Arterex’s acquisition of Phoenix S.r.l. continues its growth mission to offer customers in North America and Europe diversified, high-precision medical device manufacturing solutions.

Read MoreConsistent Shots for Consistent Shots

An integral supplier in the effort to fast-track COVID-19 vaccine deployment, Retractable Technologies turned to Arburg and its PressurePilot technology to help deliver more than 500 million syringes during the pandemic.

Read MoreCatheter Specialist Finds Sweet Spot Serving Small, Medium-Sized Concerns

Medical-component specialist LightningCath has carved a niche meeting the needs of small to medium-sized entrepreneurs with complex catheter designs … quickly.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More